Battery cell coating machine conveying mechanism capable of inhibiting coating bubbles and battery cell coating method

A technology of conveying mechanism and coating machine, which is applied in the direction of assembling battery machine, non-aqueous electrolyte battery, non-aqueous electrolyte battery, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

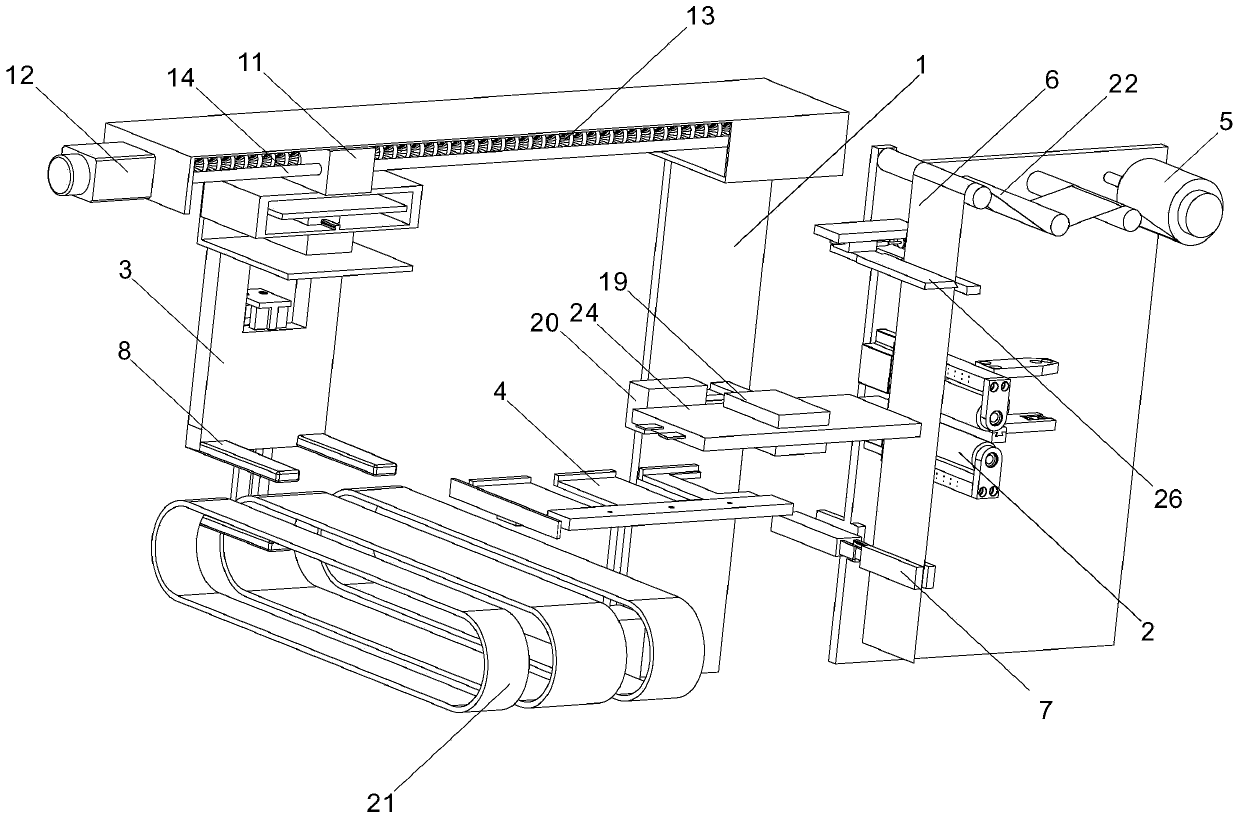

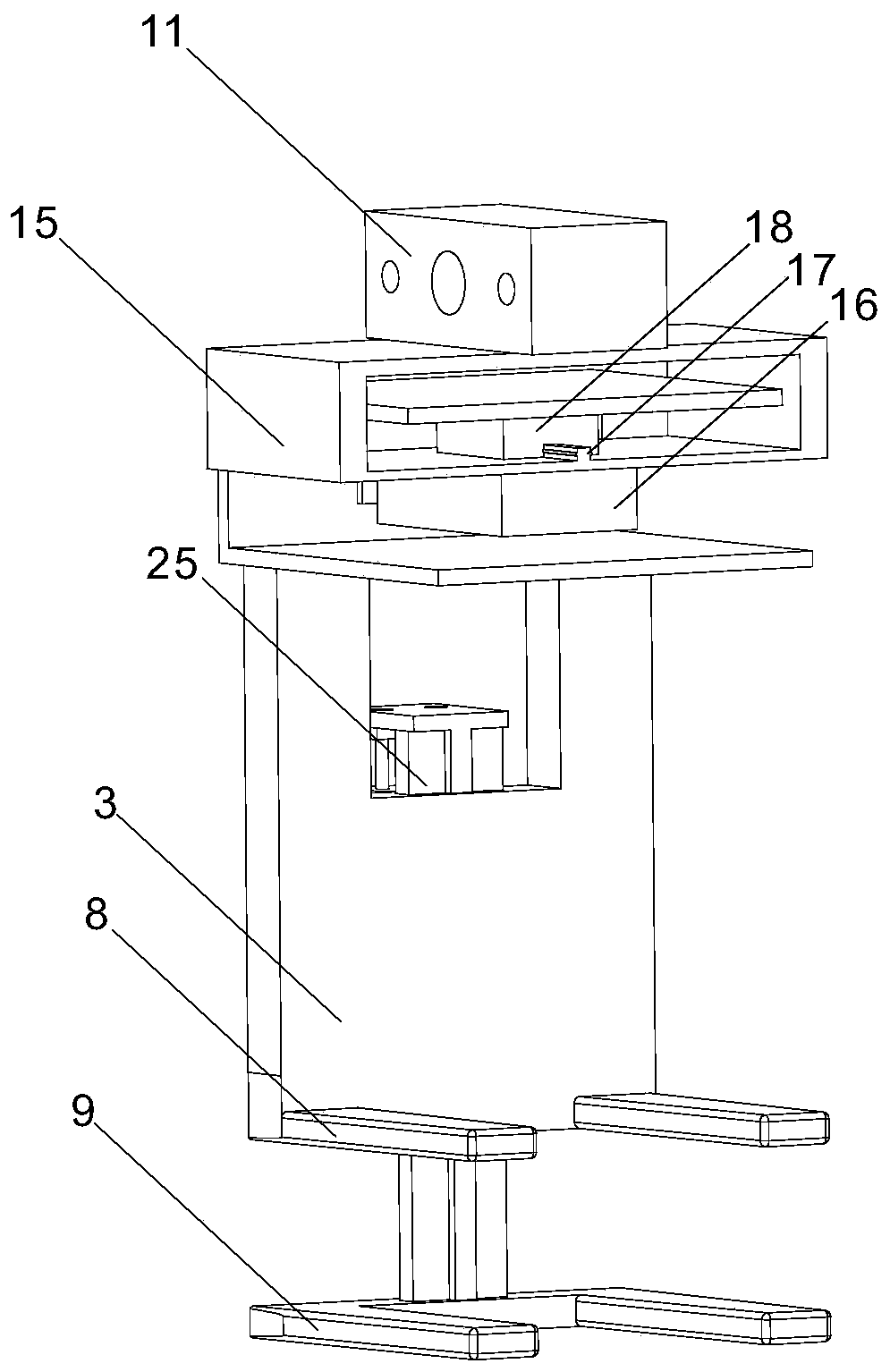

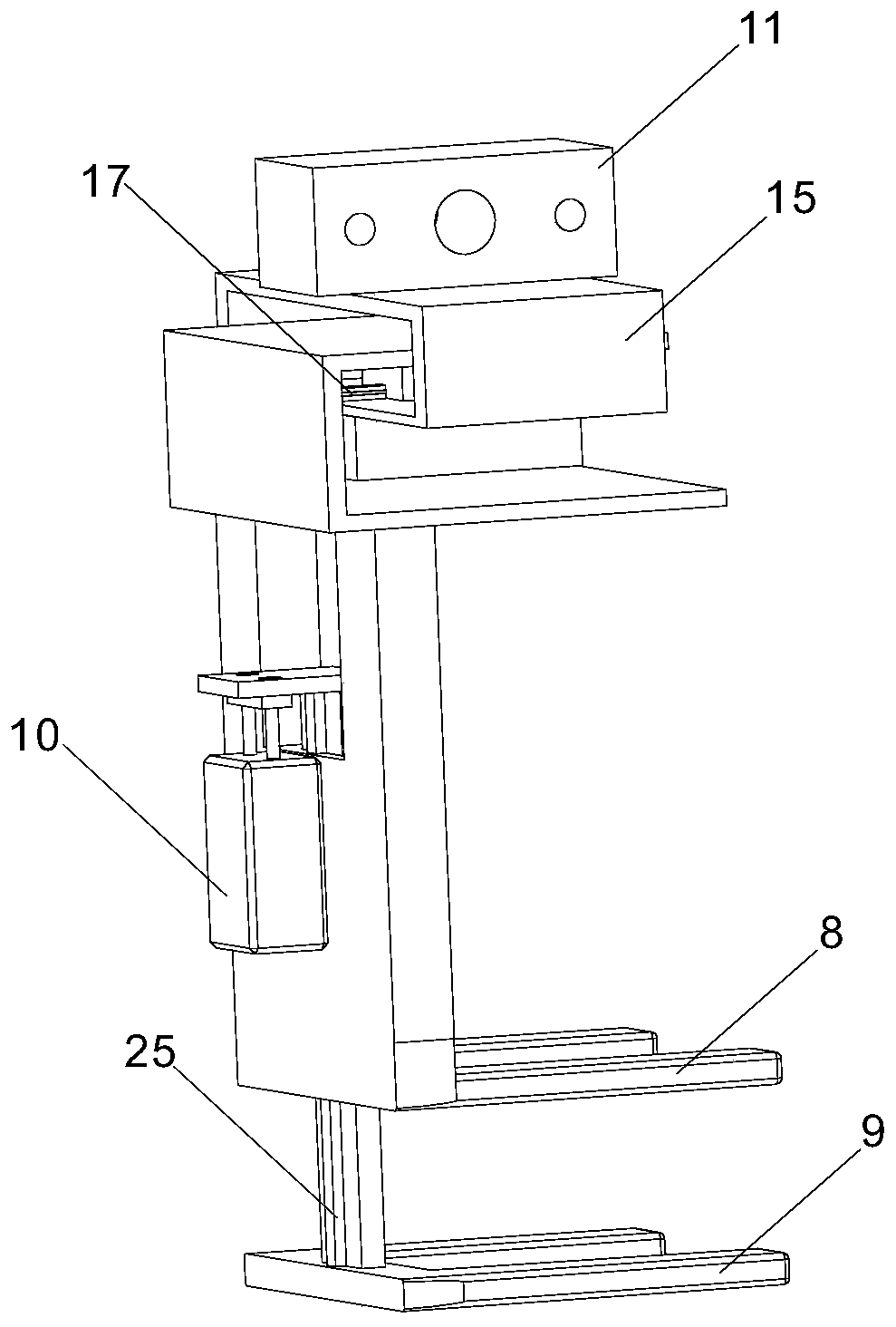

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, the conveying mechanism of the cell coating machine that suppresses the bubbles in the coating is set on the frame 1 of the cell coating machine. Roller group, a film roll shaft 5, three film-drawing rollers 22 and a film cutter 23, the film-applying roller group includes a pair of vertically arranged and parallel film-applying rollers 2, and the film-applying roller 2 is made of polyurethane with a Shore hardness of 20° , between the two laminating rollers 2, there is a return tension spring 23, the free end of the PET film 6 on the roll film shaft 5 is clamped on the lifting film clamping finger 7, and the unfolded PET film 6 moves from the positioning platform 4 and the Passes between sets of film rolls. The front end of the cell coating machine inputs the 24 workpieces of the cell that have been plastic-sealed with aluminum-plastic film through the cell conveyor belt. The conveying mechanism of the ce...

Embodiment 2

[0036] The movable splint driving device 10 is an electric cylinder. Film sticking roller 2 selects the rubber that Shore hardness is 20 ° for use. All the other are with embodiment 1.

Embodiment 3

[0038] Film sticking roller 2 selects the rubber that Shore hardness is 22 ° for use. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com