Passive Flow Direction Biasing in Low Temperature Thermosyphons

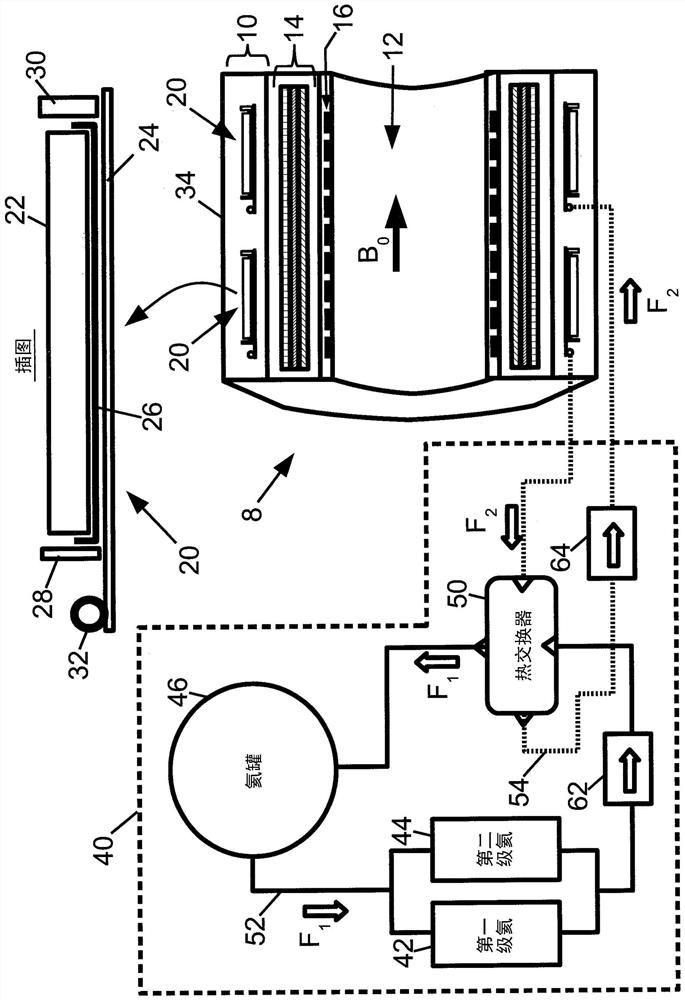

A flow direction, passive technology, applied in the direction of measuring devices, lighting and heating equipment, superconducting magnets/coils, etc., can solve the problem of high cost of liquid helium, and achieve the effect of efficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

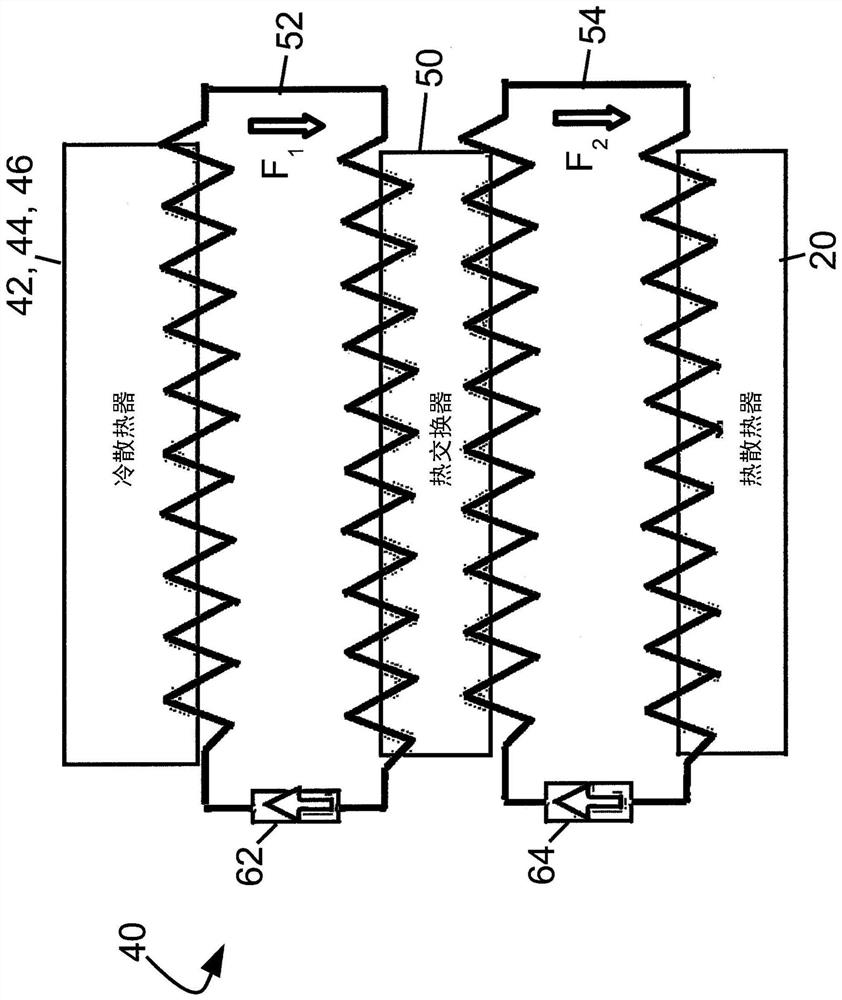

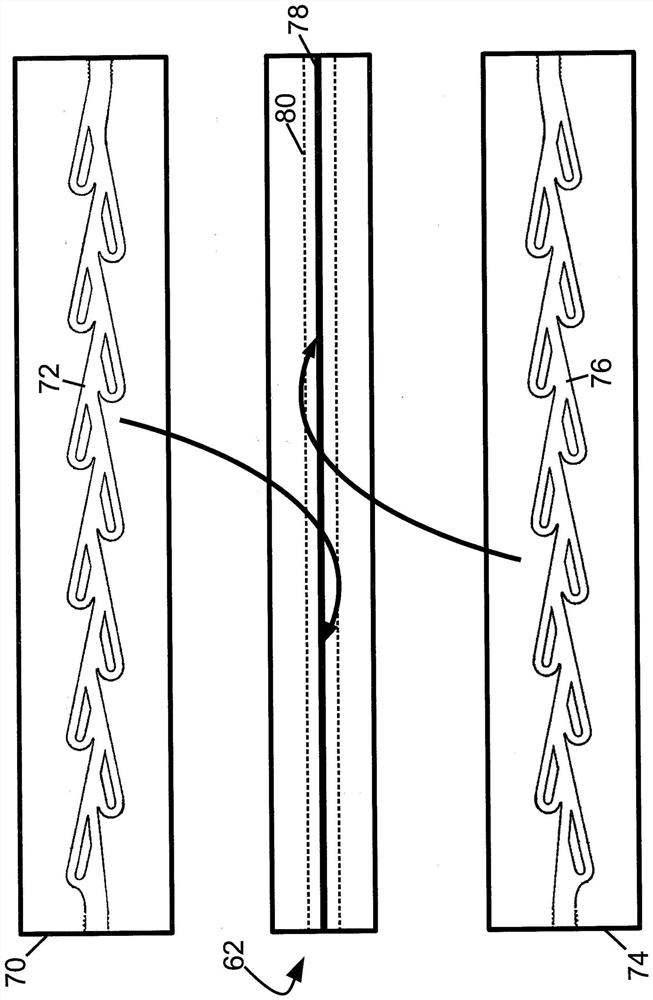

[0022] In the heat exchanger, the hotter coolant fluid flows in a flow path close to the flow path carrying the cooler coolant fluid, and heat is transferred from the hotter coolant fluid to the cooler coolant fluid, reducing The temperature of the hotter coolant fluid. In a heat exchanger, the flow of hotter coolant fluid through its flow path may be parallel to the flow of cooler coolant fluid through its flow path. Alternatively, the flow of the hotter coolant fluid through its flow path may be antiparallel to (ie, in the opposite direction of) the flow of the cooler coolant fluid through its flow path. The latter arrangement is known as a counterflow arrangement and is more efficient than a parallel flow arrangement because the average temperature difference at points along the parallel flow path is higher.

[0023] This paper recognizes that a problem with existing thermosiphon cooling installations that employ primary and secondary coolant circuits connected by heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com