A fixed zirconium silane interface modified polyvinylidene fluoride film and its preparation and application

A technology of polyvinylidene fluoride membrane and polyvinylidene fluoride, which is applied in the field of phosphorus-containing protein separation membrane and its preparation and application, can solve the problem of low efficiency of fixed metal chelation affinity technology, low specific adsorption capacity, and inability to repeat Repeated adsorption and other problems to achieve the effect of avoiding phosphorylation process, excellent adsorption effect, and improving affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

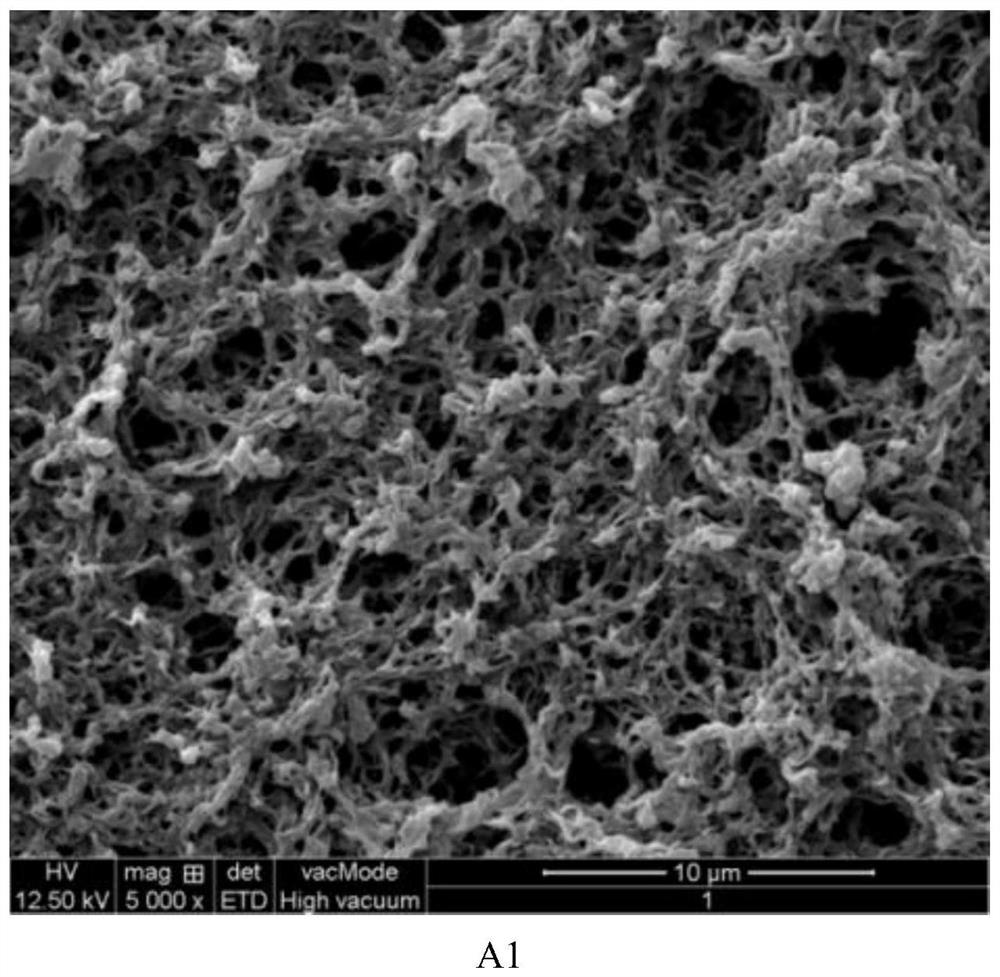

[0043] (1) Completely dissolve PVDF in triethyl phosphate (TEP) to form a PVDF solution with a mass fraction of 18%. After dissolving at 60°C for 8 hours, the casting solution is left to stand for 10 hours and poured on a 50°C scraper Squeeze the film with a 300 μm scraper, then put it into a mixture of TEP and water at a mass ratio of 1:1 and a temperature of 25°C for 5 seconds, then put it in pure water for 20 hours, and then peel it off to obtain PVDF membrane.

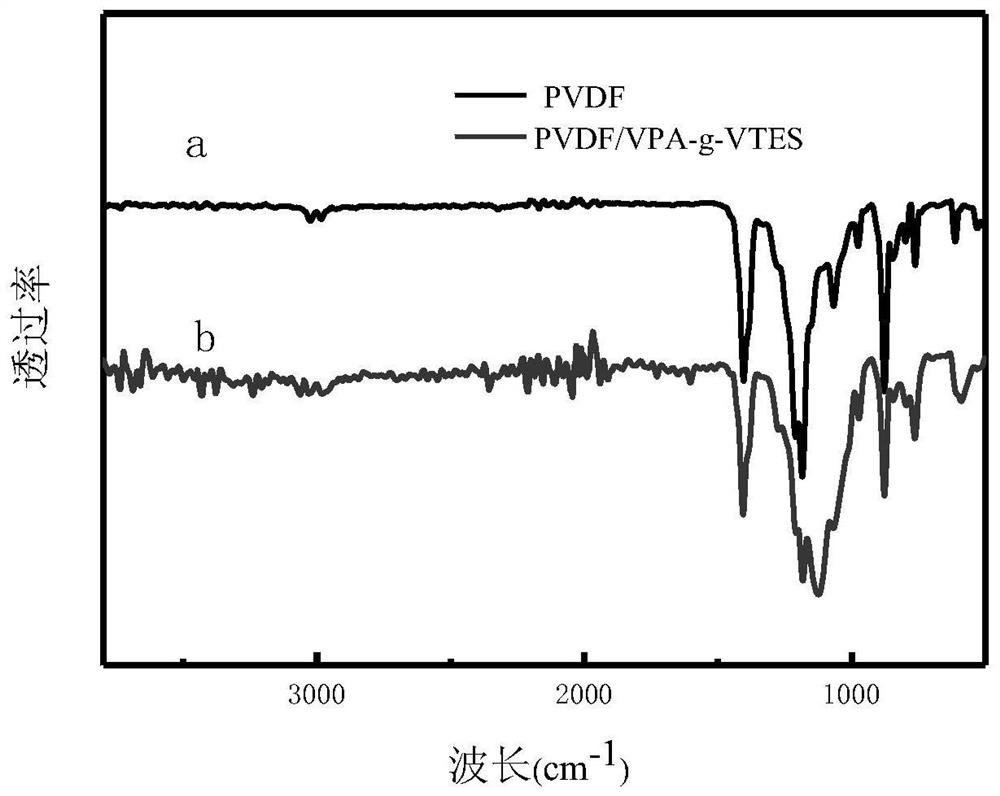

[0044] (2) Dissolve 2g of vinyl phosphoric acid (VPA), 1g of silane coupling agent vinyltriethoxysilane (VTES) and 0.05g of initiator azobisisobutyronitrile (AIBN) in 100g of triethyl phosphate at 60°C In the fusion solution of 1:1 (mass ratio) with water, polymerize for 12h, then immerse the PVDF membrane in the solution for 3h in step (1), and the prepolymer diffuses into the membrane during the immersion in the solution to obtain PVDF / VPA-g-VTES membrane.

[0045] (3) Submerge the PVDF / VPA-g-VTES membrane in ...

Embodiment 2

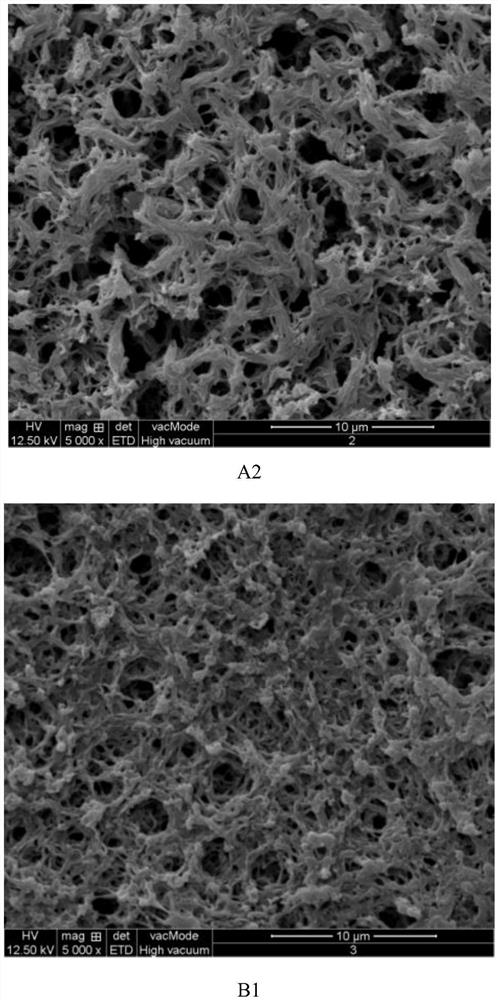

[0047] (1) Completely dissolve PVDF in triethyl phosphate (TEP) to form a PVDF solution with a mass fraction of 18%. After dissolving at 65°C for 8 hours, the casting solution is left to stand for 10 hours and poured on a 60°C scraper Squeeze the film with a 300 μm scraper, then put it into a mixture of TEP and water at a mass ratio of 1:1 and a temperature of 25°C for 5 seconds, then put it in pure water for 24 hours, and then peel it off to obtain PVDF membrane.

[0048] (2) Dissolve 2.5g vinyl phosphoric acid (VPA), 1.5g silane coupling agent vinyltriethoxysilane (VTES) and 0.06g initiator azobisisobutyronitrile (AIBN) in 100g phosphoric acid tris at 65°C In the fusion solution of ethyl ester and water 1:1 (mass ratio), polymerize for 16h, then immerse the PVDF membrane in the solution for 3h in the step (1), and the prepolymer diffuses into the membrane during the immersion in the solution, and obtains PVDF / VPA-g-VTES membrane.

[0049] (3) Submerge the PVDF / VPA-g-VTES m...

Embodiment 3

[0051] (1) Completely dissolve PVDF in triethyl phosphate (TEP) to form a PVDF solution with a mass fraction of 15%, dissolve it at 70°C for 9 hours, then let the casting solution stand for 10 hours and pour it on a 60°C scraping plate , use a 500μm scraper to scrape the film, then put it into a mixture of TEP and water with a mass ratio of 2:1 and a temperature of 25°C for 5s, then put it in pure water for 24h, and then peel it off to obtain PVDF membrane.

[0052] (2) Dissolve 2.5g vinyl phosphoric acid (VPA), 1.5g silane coupling agent vinyltriethoxysilane (VTES) and 0.06g initiator azobisisobutyronitrile (AIBN) in 100g phosphoric acid tris at 70°C In the fusion solution of ethyl ester and water 1:1 (mass ratio), polymerize for 24h, then immerse the PVDF membrane in the solution for 3h in the step (1), and the prepolymer diffuses into the membrane during the immersion in the solution, and obtains PVDF / VPA-g-VTES membrane.

[0053] (3) Submerge the PVDF / VPA-g-VTES membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com