Method for preparing bright red iron red hybrid pigment from iron tailings

An iron tailings, red technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of complex composition of iron tailings, complicated mechanism of action, etc., to achieve rich reserves and improve chromaticity. , the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Disperse 2.0 g of ball-milled iron tailings powder in 60 mL of an aqueous solution of 0.37 mol / L ferric chloride, fully stir (2500 r / min, 2 h) and ultrasonic (30 min) and then add 1 g of sodium hydroxide , 1mL of ammonia water (ammonia water mass fraction: 28wt.%; total base molar weight: 0.0398mol), after stirring vigorously at a speed of 4800r / min for 30min, continue stirring (1500r / min) and ultrasonication for 2h each to obtain a uniform suspension, the The suspension was transferred to a hydrothermal reaction kettle, reacted at 160°C for 24 hours, cooled naturally to room temperature, centrifuged, washed, dried, ground, and sieved to obtain a bright red iron red hybrid pigment.

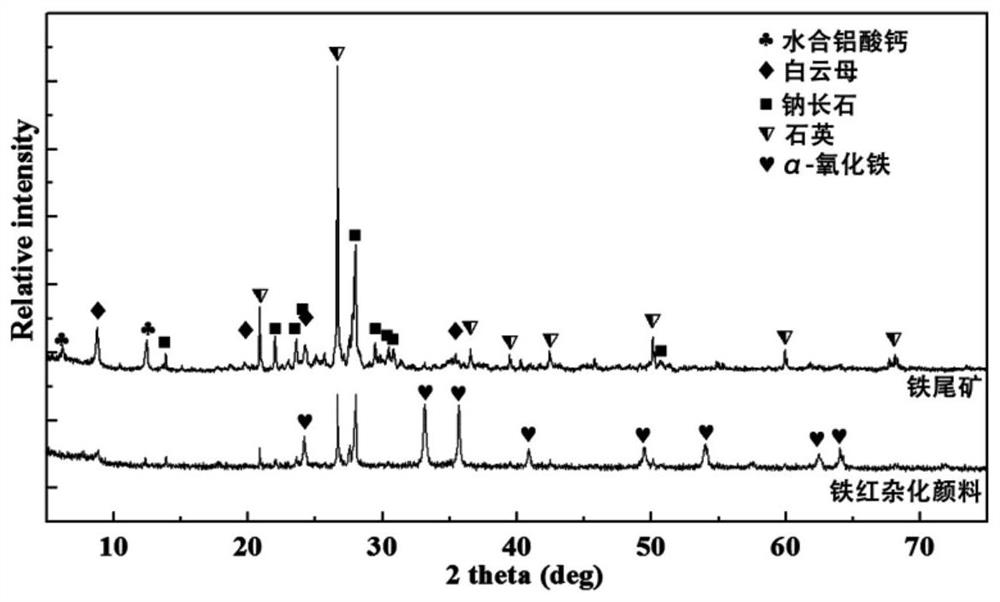

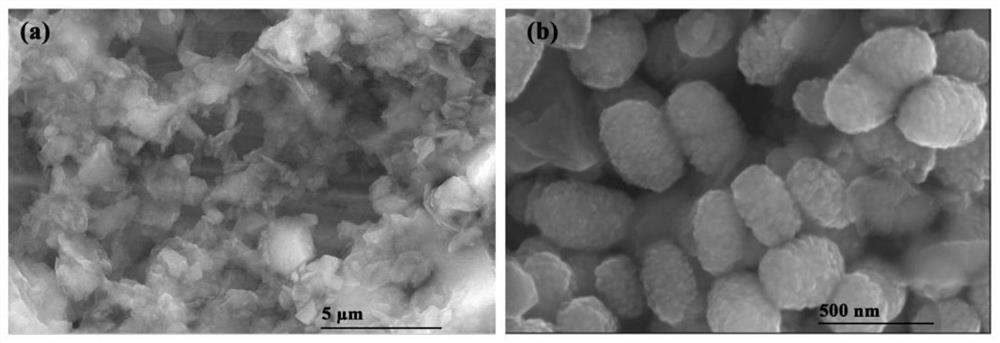

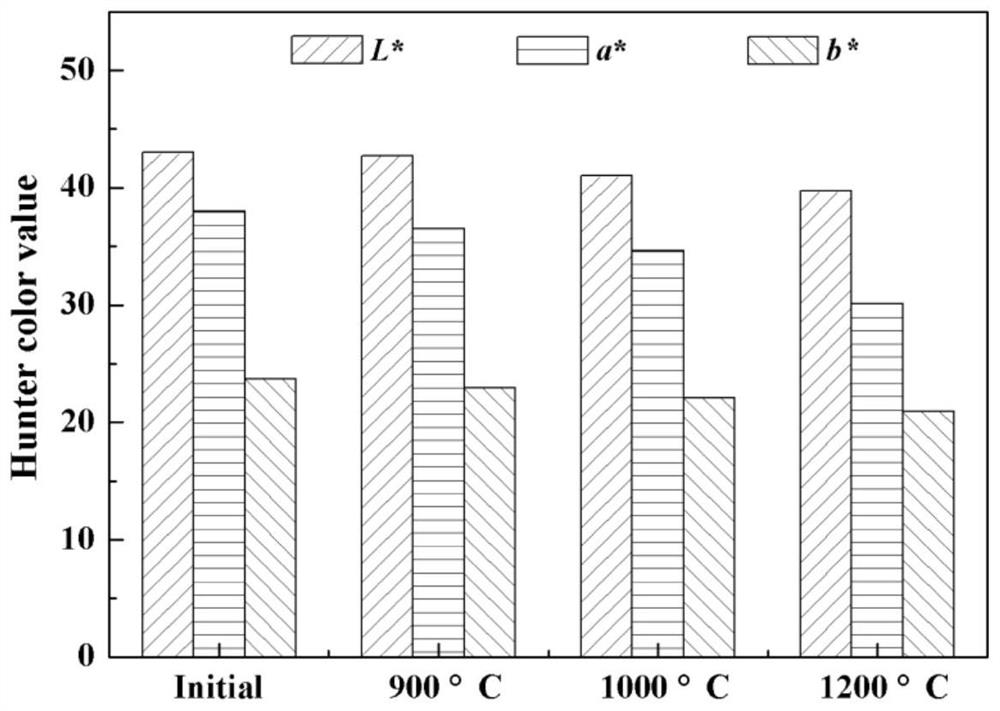

[0023] The main phase composition of the obtained iron red pigment is α-Fe 2 o 3 , albite, quartz (such as figure 1 shown); the shape is relatively regular, which is similar to the shape of silkworm cocoon, and the particle size is 160nm (such as figure 2 shown); the a* value...

Embodiment 2

[0024] Example 2: Disperse 4.0 g of iron tailings powder in 60 mL of an aqueous solution with a concentration of 0.18 mol / L ferric chloride and 0.21 mol / L ferric sulfate, fully stir (3000 r / min, 2 h) and ultrasonic (1.5 h) Then add 6mL of ammonia water (ammonia water mass fraction: 28wt.%; molar weight: 0.0888mol), stir vigorously at a speed of 4500r / min for 30min, then continue to stir (1500r / min) and ultrasonic for 1h each to obtain a uniform suspension. Transfer to a hydrothermal reaction kettle, react at 180°C for 12 hours, cool naturally to room temperature, centrifuge, wash, dry, grind, and sieve to obtain a bright red iron red hybrid pigment with a particle size of 210nm and a* value as high as 35.9, b* value is 22.1, and L* value is as high as 44.2, indicating that its color is bright (the chromaticity is tested by CR-400 / 410 of Beijing Kemei Runda Instrument Equipment Co., Ltd.).

Embodiment 3

[0025] Embodiment 3: the iron tailings powder of 3.0g is dispersed in the aqueous solution that 60mL concentration is 0.74mol / L ferric nitrate, fully stir (2000r / min, 1h) and ultrasonic (1.5h) add 3mL ammoniacal liquor (ammonia liquor mass fraction : 28wt.%), 3g sodium metasilicate (total alkali molar weight: 0.0602mol), after vigorously stirring at a speed of 5000r / min for 30min, continue to stir (2000r / min, 2h) and ultrasonic (30min) to obtain a homogeneous suspension, The suspension was transferred to a hydrothermal reaction kettle, reacted at 200°C for 6 hours, cooled naturally to room temperature, centrifuged, washed, dried, ground, and sieved to obtain a bright red iron red hybrid pigment with a particle size of 190nm. The a* value is as high as 33.9, the b* value is 23.2, and the L* value is as high as 42.7, indicating that its color is bright (the chromaticity is tested by CR-400 / 410 of Beijing Kemei Runda Instrument Equipment Co., Ltd.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com