A method for improving the stability and bonding strength of an RFID anti-uncovering fragile label

A paste strength and stability technology, applied in the field of RFID tags, can solve the problems of insufficient paste strength, waste of time and manpower, difficult to use in batches, etc., to achieve the effect of improving labeling efficiency, stability, and paste strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

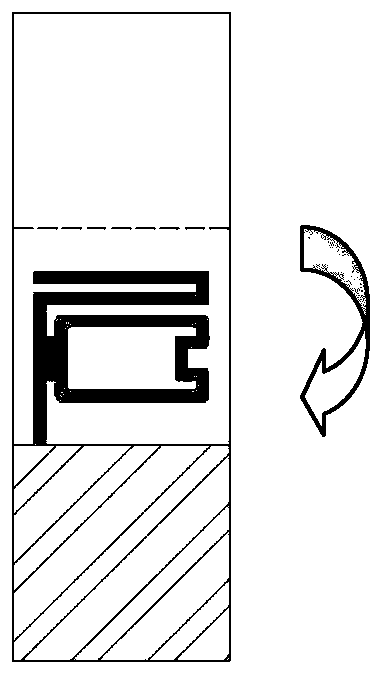

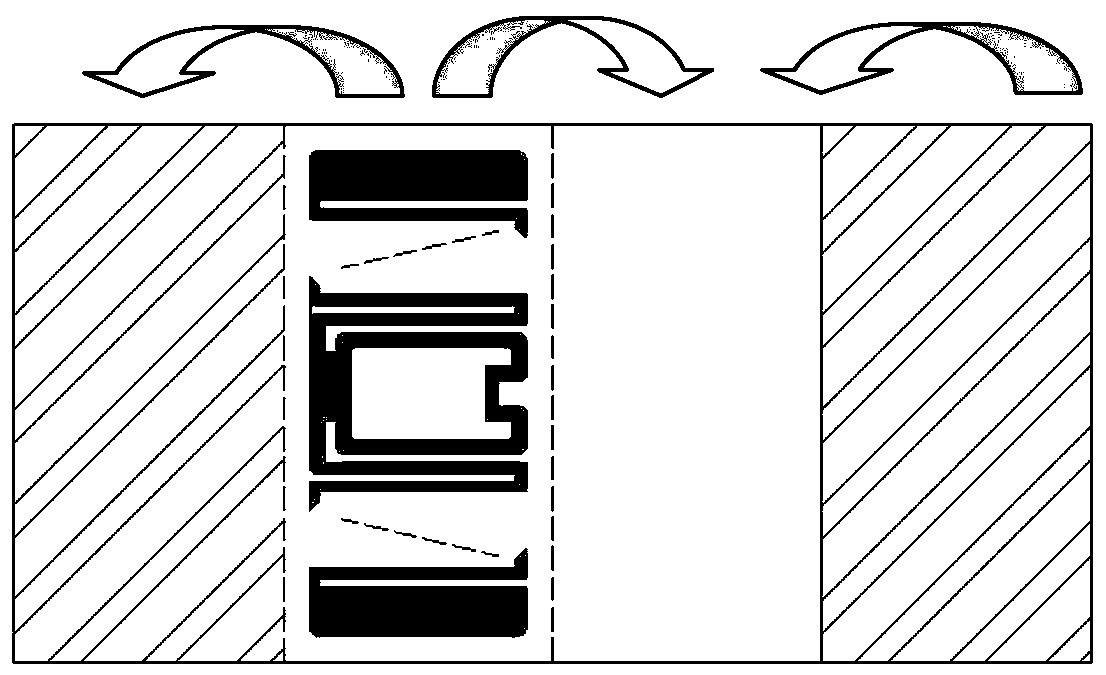

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] like Figure 3-8 As shown, a method for improving the stability and sticking strength of RFID anti-tampering fragile labels, the method is as follows:

[0027] (1) preparing the label substrate layer;

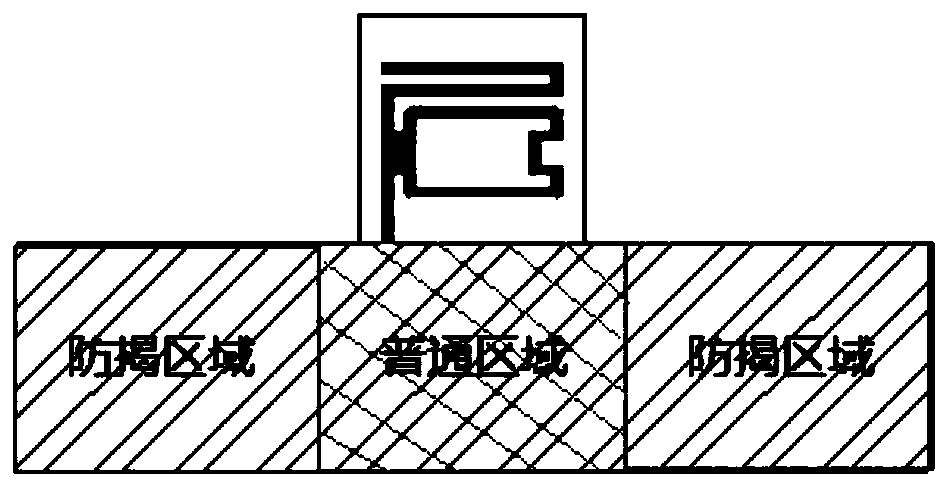

[0028] (2) Prepare the label antenna layer, the antenna layer is composed of the antenna area and the tamper-proof area, and the antenna area and the tamper-proof area are vertically intersected;

[0029] (3) gluing the antenna layer and the substrate layer;

[0030] (4) prepare the face material layer;

[0031] (5) Gluing the face material layer onto the antenna layer;

[0032] (6) Die-cutting with a destroying knife is performed on the surface of the face material layer.

[0033] The first example is image 3 As shown, a method to improve the stability and sticking strength of RFID tamper-evident and fragile labels: the tamper-evident area and the ordinary are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com