Pixel defining layer, color filter film and manufacturing method, self-luminous display panel

A technology of pixel definition layer and color filter film, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of high process complexity of inkjet printing technology, improve display performance, reduce film formation complexity, and increase cost. Effect of Membrane Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

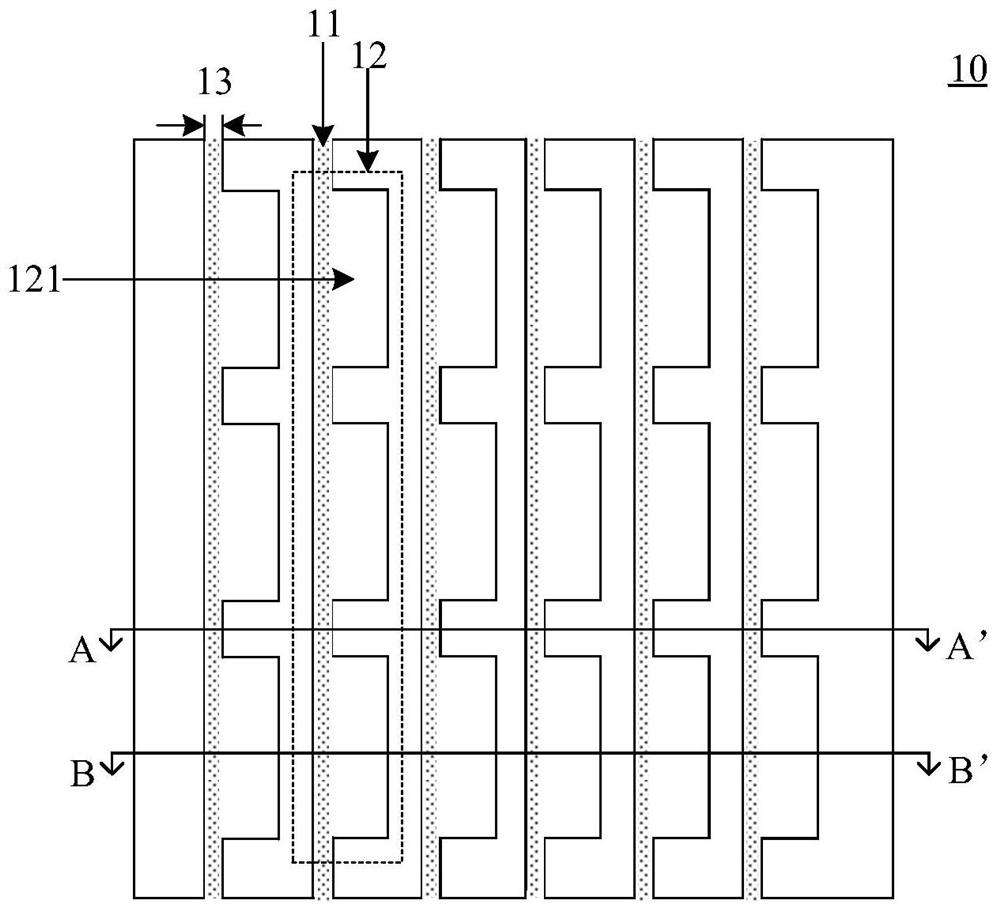

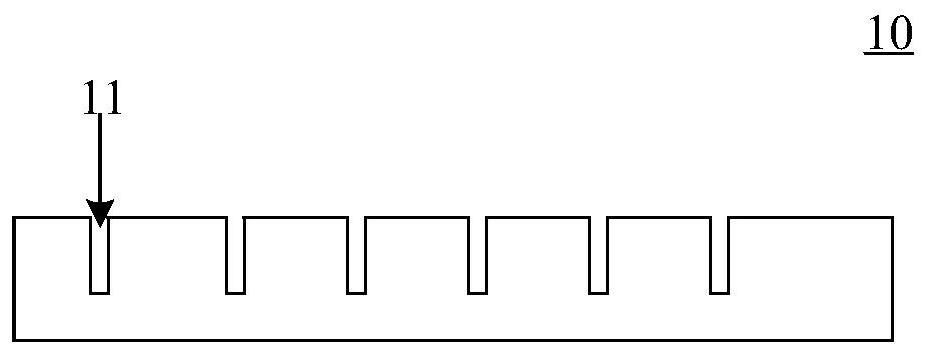

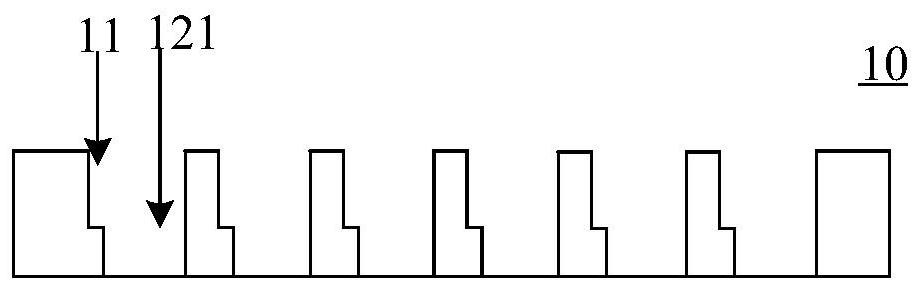

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0056] Compared with liquid crystal display panels (English: Liquid Crystal Display, abbreviation: LCD), self-luminous display panels have the advantages of self-luminescence, fast response, wide viewing angle, high brightness, bright colors, power saving and lightness, etc. The next-generation flat-panel display technology is one of the most concerned technologies in the flat-panel display technology. The self-luminous display panel may be an organic light emitting diode (English: Organic Light Emitting Display, abbreviation: OLED) display panel or a quantum dot light emitting diode (English: Quantum Dot Light Emitting Diodes, English: QLED).

[0057] In the manufacturing process of the self-luminous display panel, the colorization te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com