Loading hole unit welding tool for reaction wall and reaction pedestal

A technology of counter force pedestal and welding tooling, which is applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problem of far-reaching construction accuracy, and achieve the effect of ensuring position and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

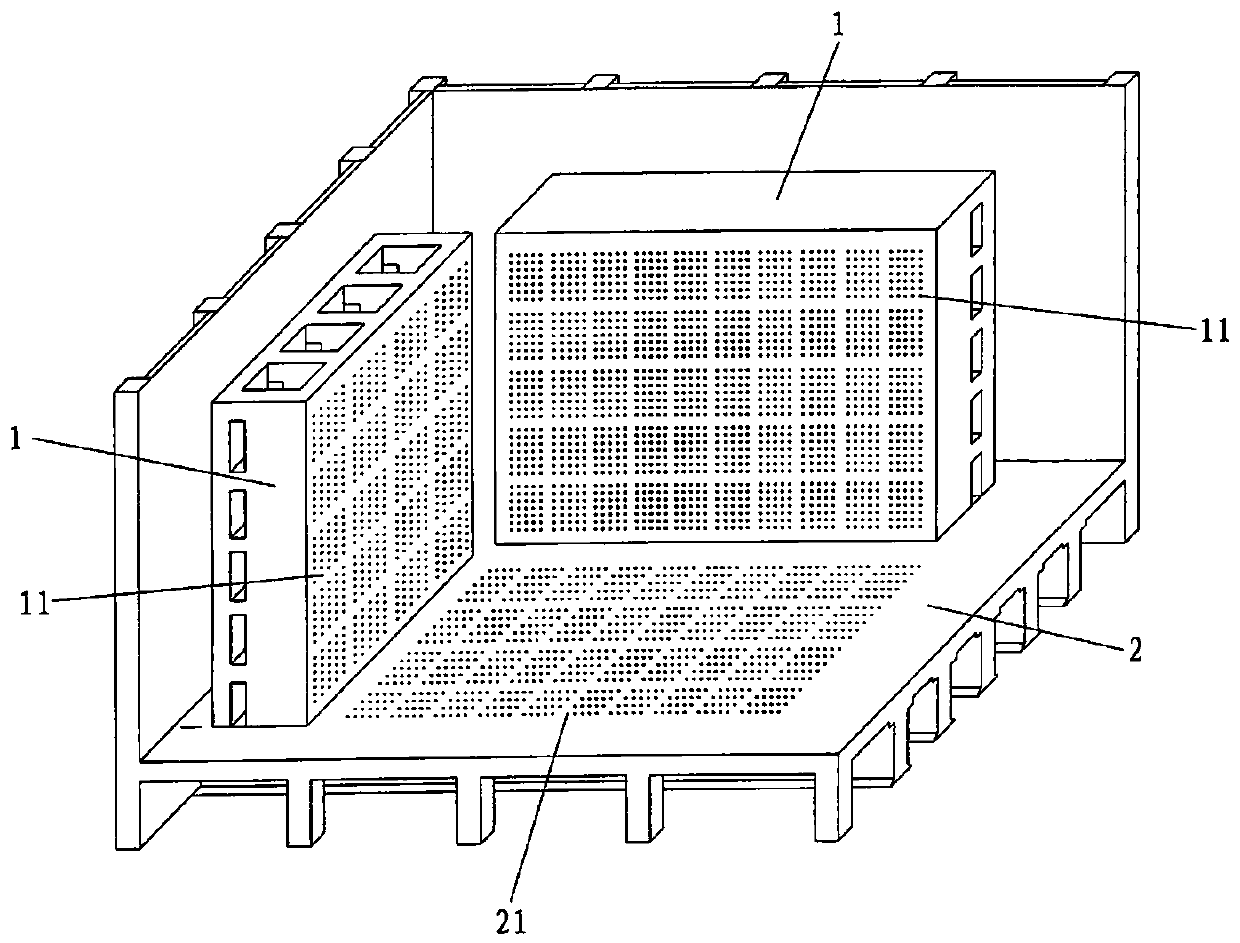

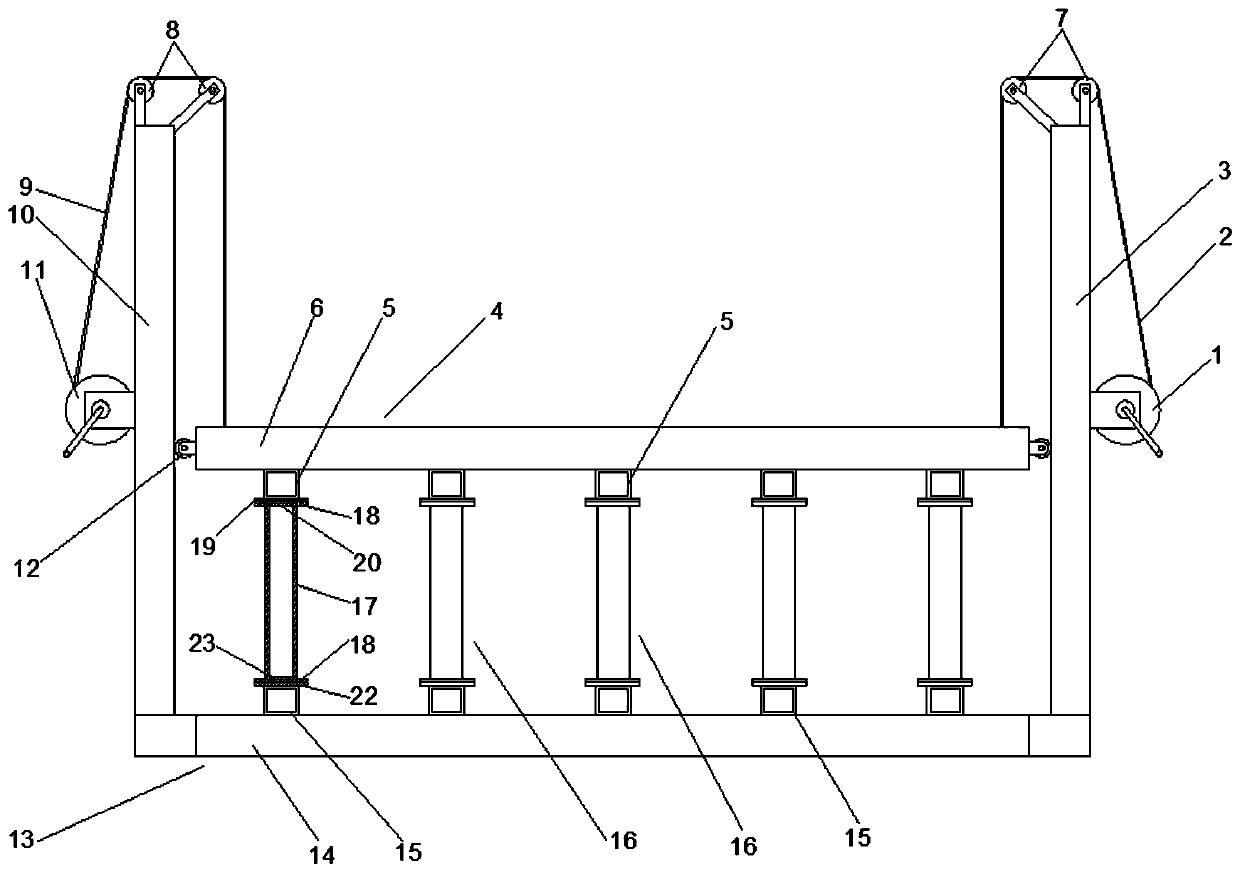

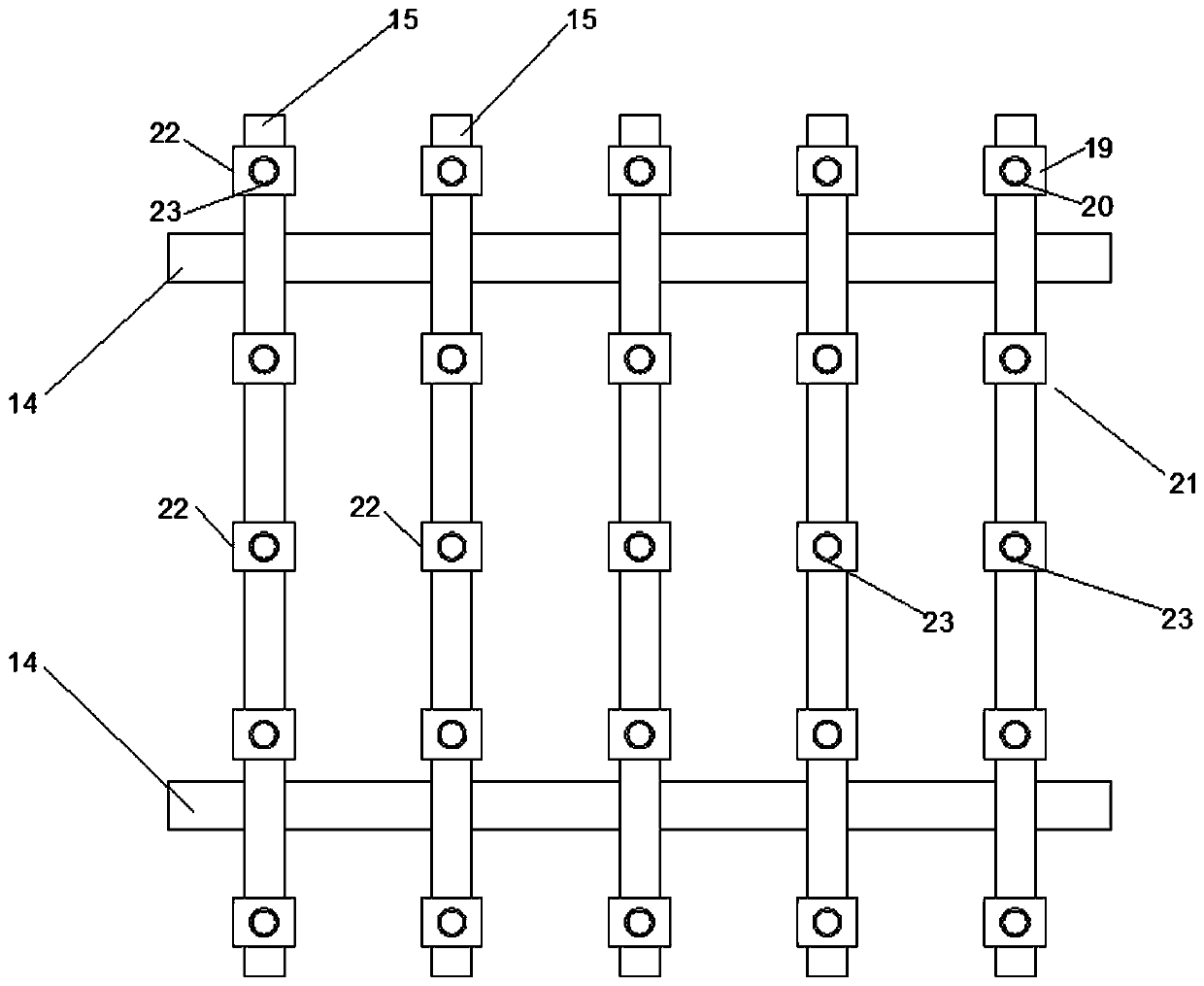

[0026] An embodiment of a loading hole unit welding tool for a reaction wall and a reaction pedestal Figure 2~12 Shown: including the tooling bracket, the tooling bracket is provided with a bottom support 13 and a counterweight pressure bearing 6 arranged opposite to the bottom support 13, and the tooling bracket is provided with a transmission connection with the counterweight pressure bearing 6 to drive The support lifting mechanism for the counterweight pressure bearing to move up and down. In this embodiment, the tooling support includes a left pillar 10 and a right pillar 3 fixed on the left and right sides of the bottom support, and the support lifting mechanism includes a The left reel 11 on the left side of the pillar 10 and the right reel 1 arranged on the right side of the right column 3, the left steel wire rope 9 is wound on the left reel 11, the right steel wire rope 2 is wound on the right reel 1, and the support lifting mechanism Also comprise the left side rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com