A clamping and conveying device for a square substrate with a hole

A square substrate, clamping transmission technology, applied to the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problem of not being able to absorb porous substrates, etc., to achieve firm grasping, accuracy assurance, and easy replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below with reference to the drawings.

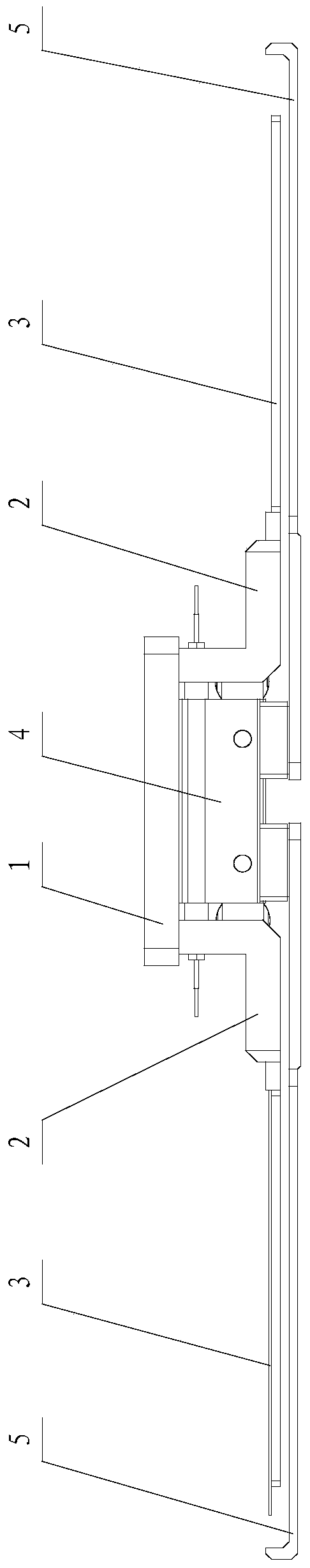

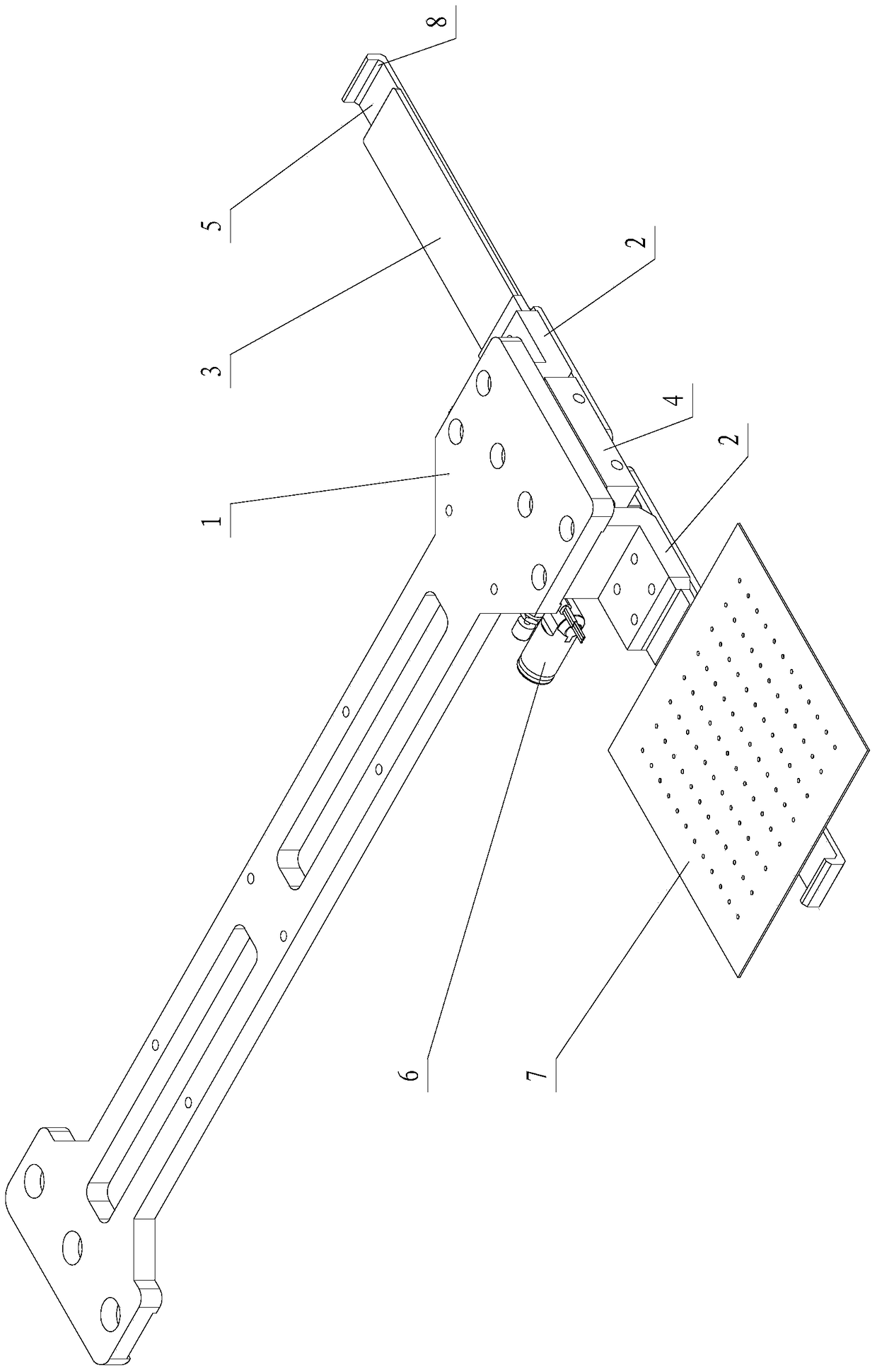

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a manipulator mounting base 1, a linear finger mounting base 2, a linear finger 3, a two-way sliding table 4, and an L-shaped finger 5. One end of the manipulator mounting base 1 is connected to the manipulator and moves with the manipulator. A two-way sliding table 4 is installed on the lower surface of the other end, and two inline finger mounting seats 2 are symmetrically provided on both sides of the two-way sliding table 4.

[0019] Each inline finger mounting seat 2 is of an "L" shape and is fixed on the lower surface of the manipulator mounting seat 1, and each inline finger mounting seat 2 is fixedly connected to a font finger 3.

[0020] The inline fingers 3 on both sides of the two-way sliding table 4 are arranged symmetrically at the same height, each inline finger 3 is rectangular, one end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com