Hole machining fixture for irregular thin-wall cavity parts

An irregular hole processing technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machine parts, etc., can solve the problem that the annular thin-walled parts cannot fit with the stepped surface, the lower end surface of the annular thin-walled parts is uneven, and the annular thin-walled parts cannot be applied. Thin-walled parts, etc., to achieve a wide range of applications, ensure the tolerance of aperture size and shape and position, and reduce the rate of rejection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

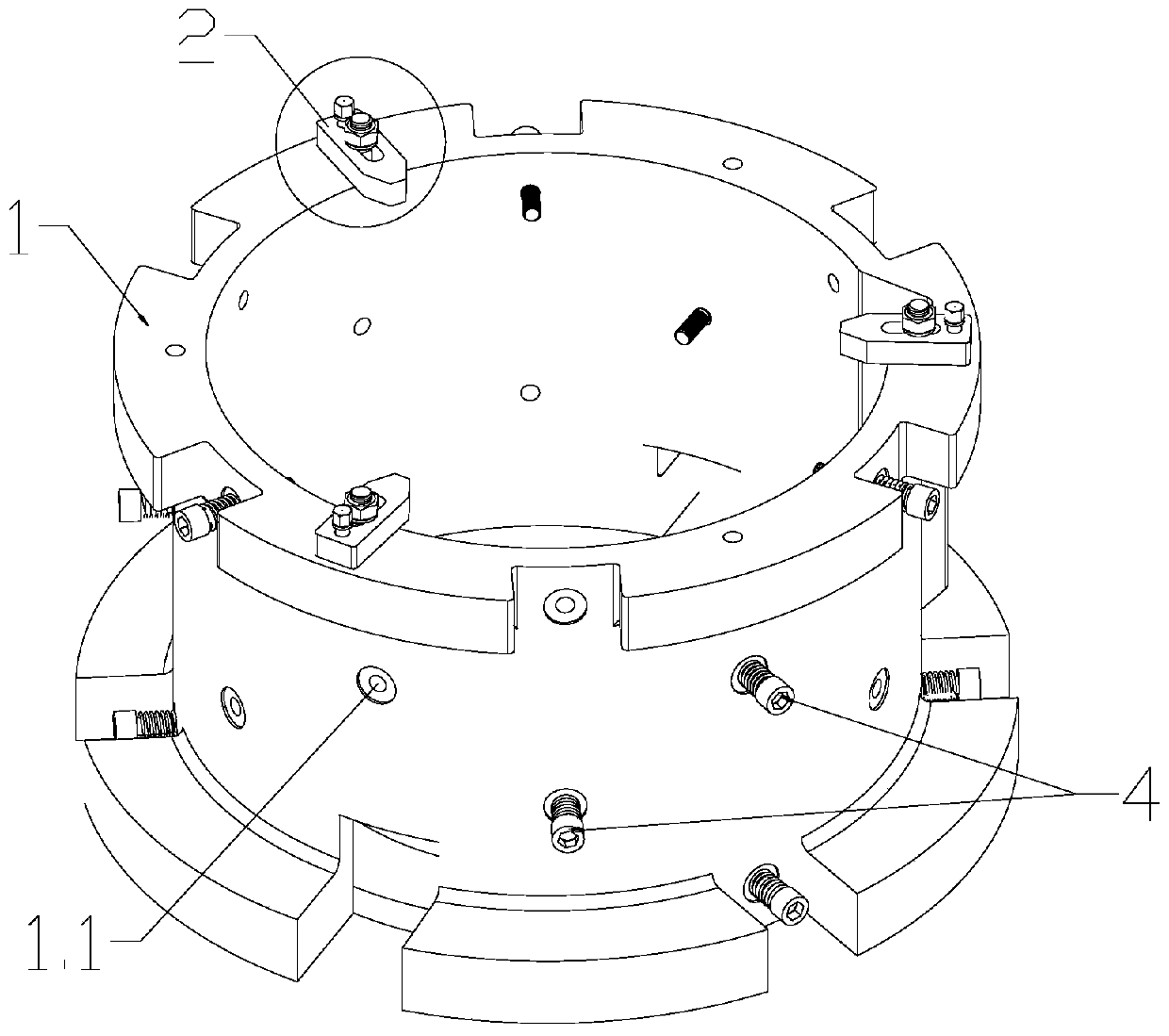

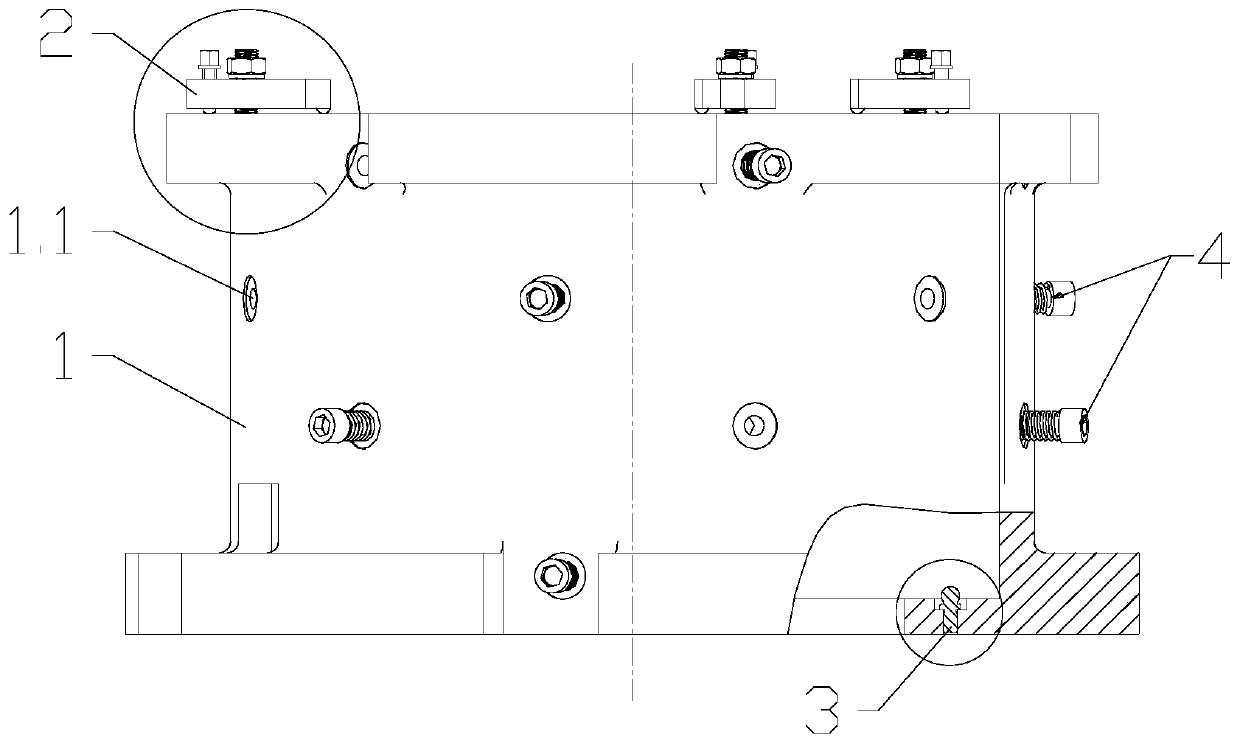

[0029] see Figure 1-6 , the present invention relates to a fixture for hole processing of irregular thin-walled cavity parts, which includes a fixture body 1, a top pressing assembly 2, a support nail 3 and a middle pressing assembly 4, and the workpiece 5 is an irregular thin-walled As for the cavity part, the workpiece 5 is placed in the cavity of the fixture body 1 .

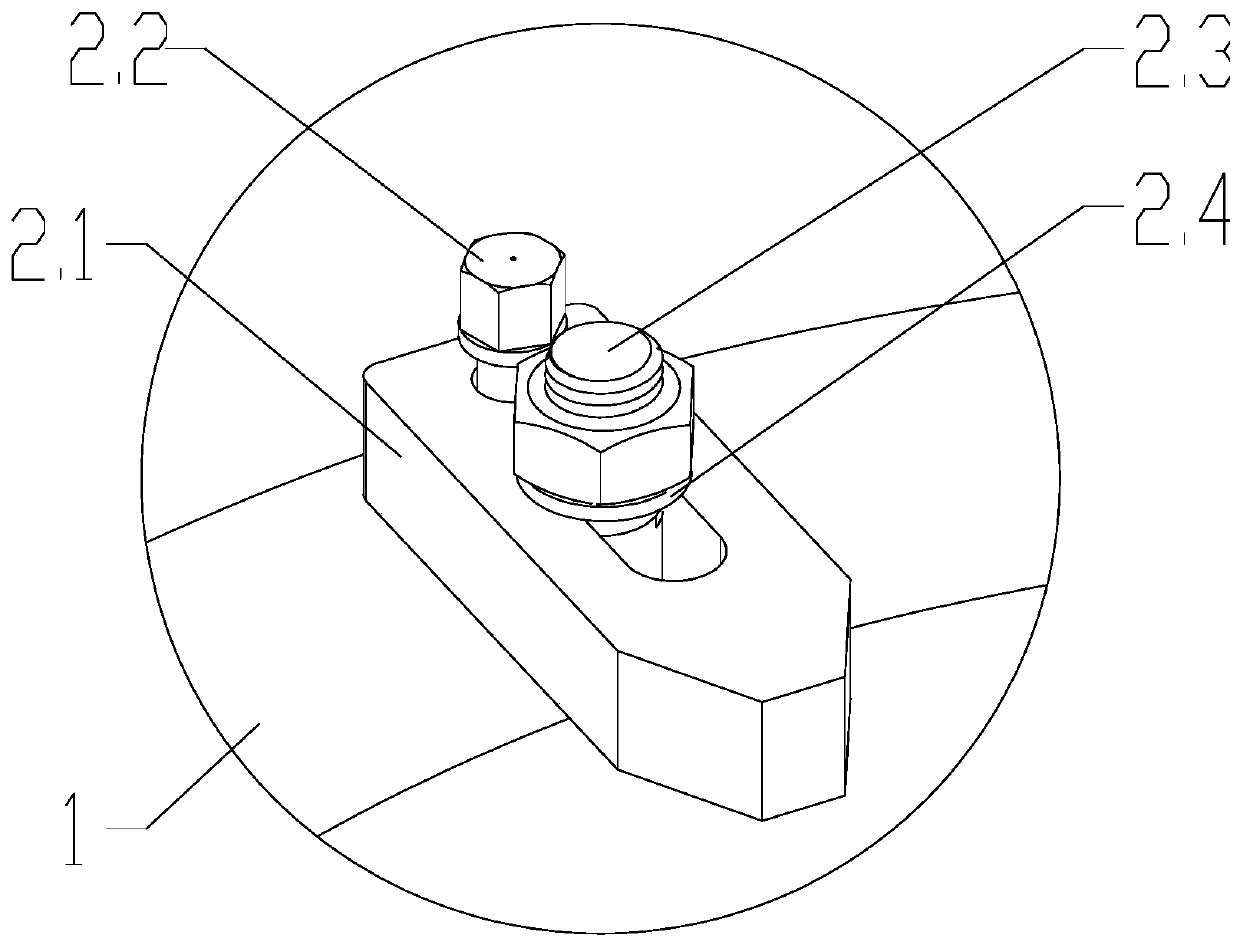

[0030] There are three top pressing components 2, which are evenly arranged on the top of the fixture body 1. The top pressing component 2 includes a pressure plate 2.1, a support screw 2.2 and a locking bolt 2.3. The outer end of the pressure plate 2.1 is against the upper surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com