Self-adsorption type vacuum sucker of crawling robot

A technology of crawling robot and vacuum suction cup, which is applied in the directions of motor vehicles, transportation and packaging, can solve the problems of high cost, difficult control, complex structure, etc., and achieve the effect of saving equipment cost, avoiding insufficient adsorption force, and simplifying the overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

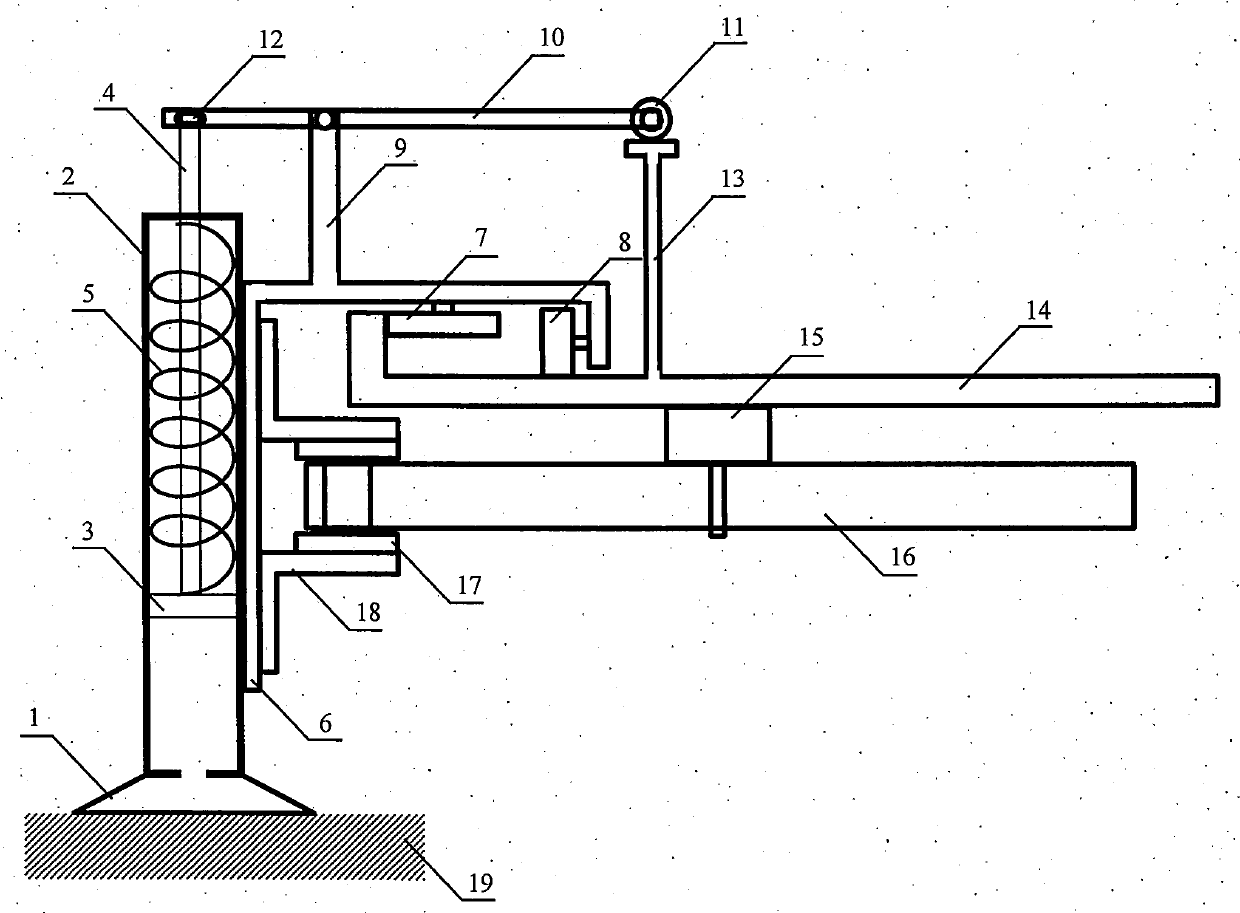

[0019] The present invention is realized through the following technical solutions:

[0020] Self-absorbing vacuum chuck for crawling robot, including vacuum chuck 1, cylinder block 2, piston 3, piston connecting rod 4, helical tension spring 5, bracket connected with chain attachment 6, horizontal wheel 7, longitudinal fixed wheel 8, Lever support 9, linkage lever 10, lever rolling wheel 11, U-shaped sliding groove 12, lever movement support 13 etc. are formed, and described cylinder is made up of cylinder block, piston, piston connecting rod and helical extension spring, and described The cylinder is composed of a cylinder block 2, a piston 3, a piston connecting rod 4 and a helical tension spring 5, and the connecting bracket is composed of a bracket 6 connected to the chain attachment, a horizontal wheel 7, a vertical fixed wheel 8, and a lever support 9.

[0021] The piston 3 and the helical tension spring 5 are placed inside the cylinder body of the cylinder, and the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com