Improved container binding system for ship

A container and improved technology, which is applied in the direction of deck loading, devices to prevent multi-way movement of goods, etc., can solve the problems of positioning and fastening of containers of different heights, easy to loose adjustment, etc., to achieve precise height adjustment and wide application range. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

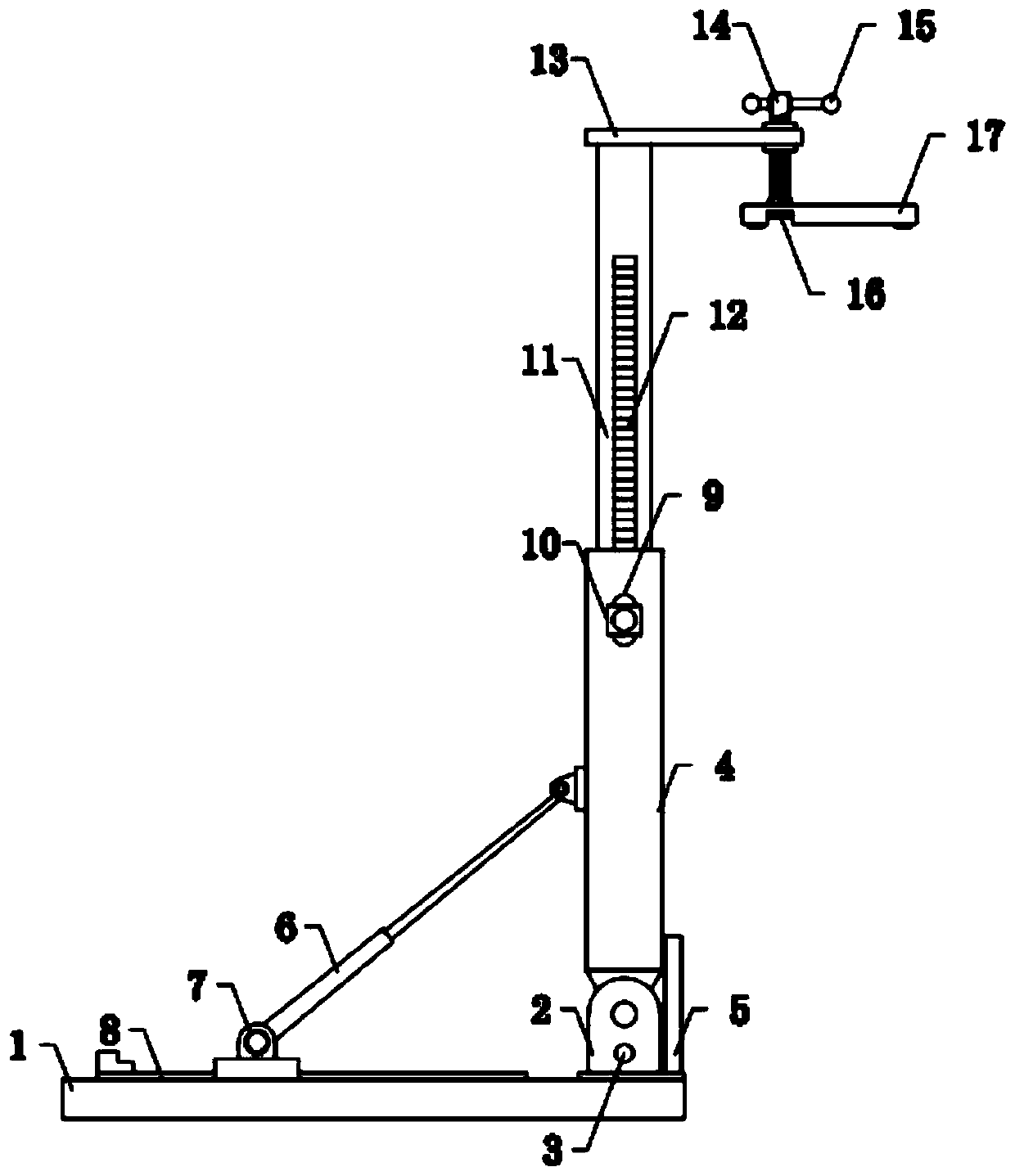

[0030] see Figure 1-6 , the present invention provides a technical solution: an improved marine container lashing system, including a support base plate 1 and a pin seat assembly 2 fixed on the right side of the upper surface of the support base plate 1 by screws, and the upper side of the pin seat assembly 2 passes through The pin shaft is connected with a support sleeve 4, and the support sleeve 4 can rotate relative to the pin shaft seat assembly 2 through the setting of the pin shaft, so as to facilitate the installation and fastening operation of the container;

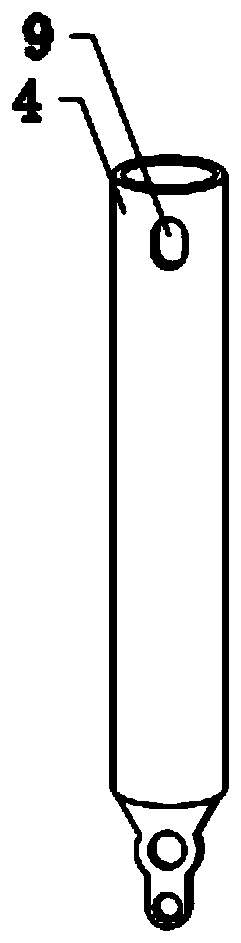

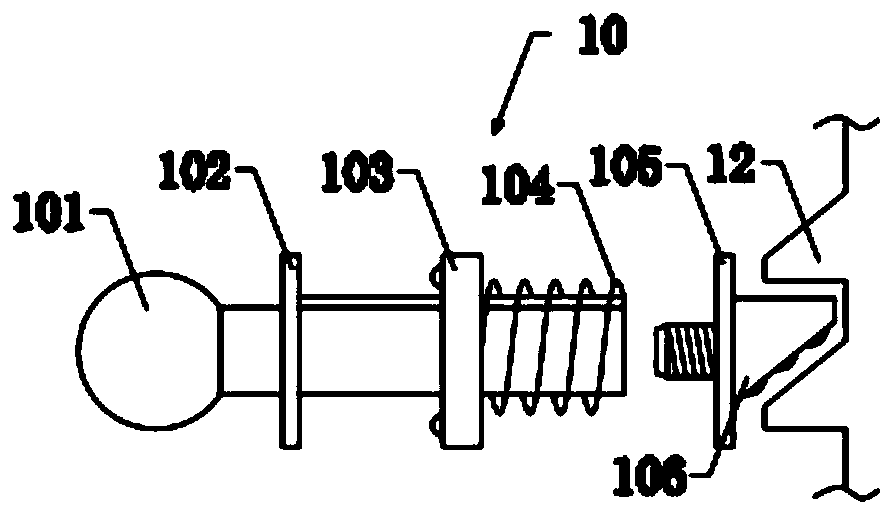

[0031] The outer wall of the support sleeve 4 is provided with a mounting groove 9 along the axial direction of the support sleeve 4, and a position-limiting tooth mechanism 10 is embedded in the mounting groove 9. The inner cavity of the support sleeve 4 is longitudinally inserted with a column 11, and the column 11 A positioning rack 12 is arranged on the front wall along the axial direction of the column 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com