Automatic adsorption counting device for rhinestones

A technology of moving devices and points, applied in packaging and other directions, can solve the problems of large gaps in the number of hot drills, different, slow distribution of finished products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

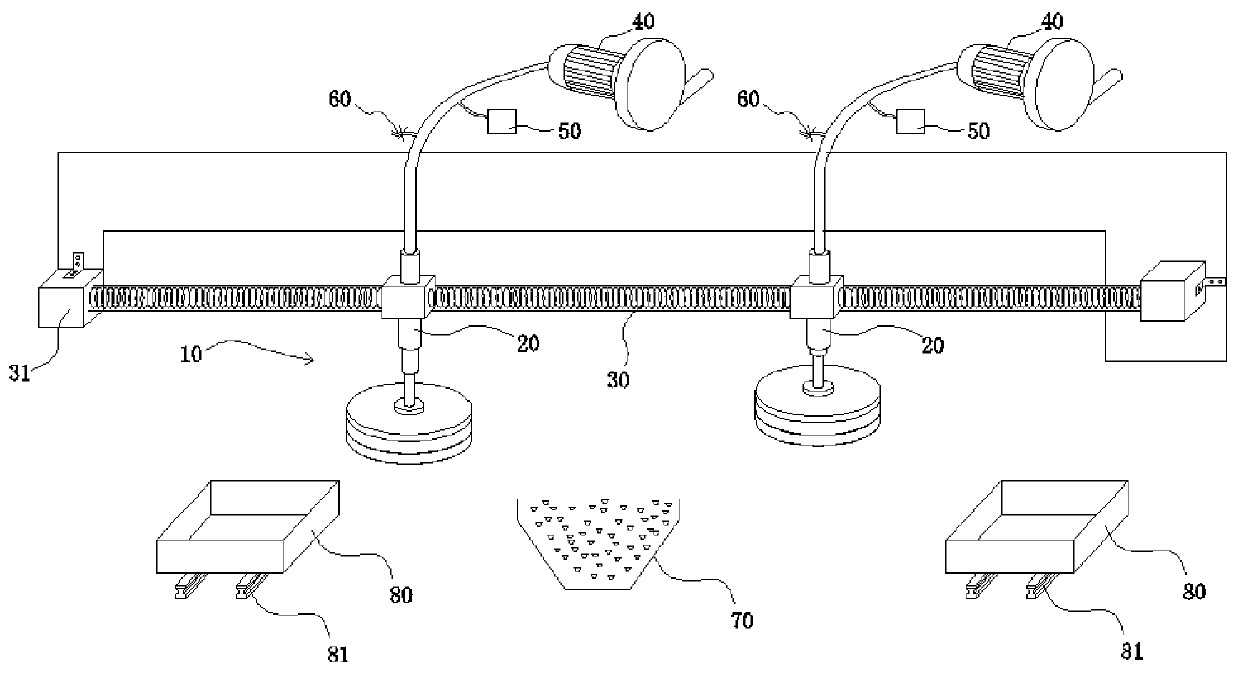

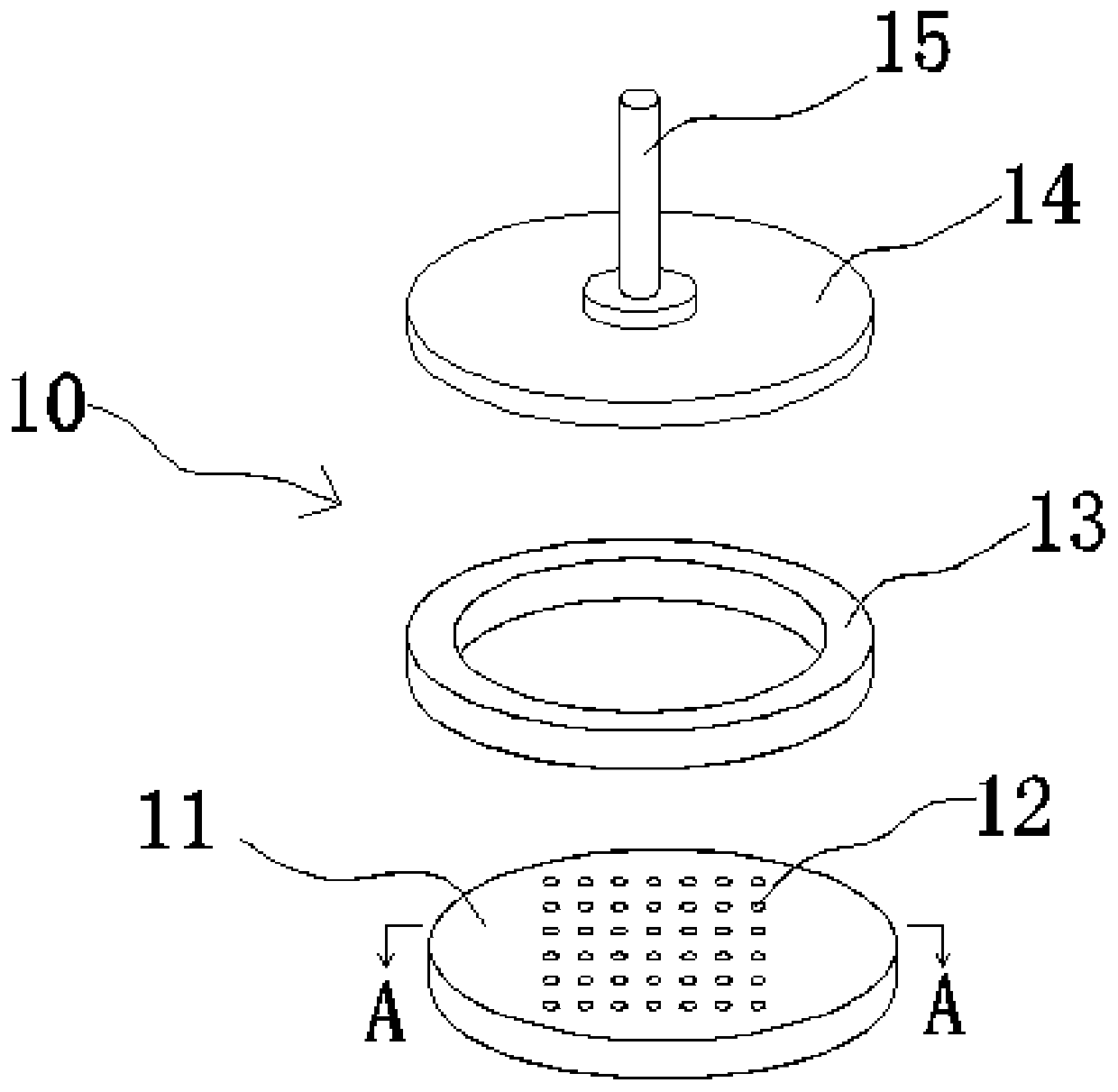

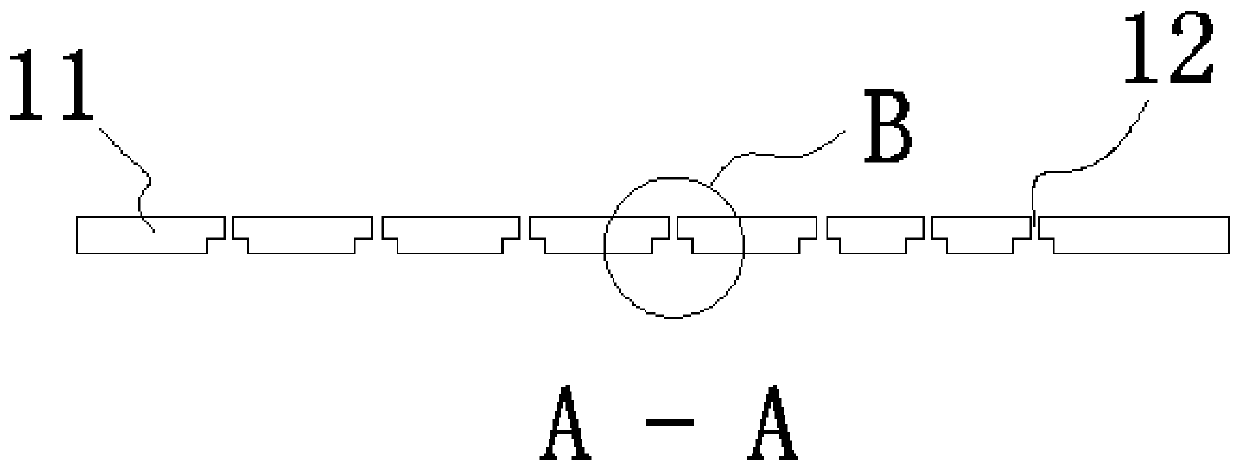

[0022] like Figure 1-5 Shown, a kind of automatic adsorption points device of hot drill of the present embodiment comprises hot drill adsorber 10, the mobile device that makes hot drill adsorber 10 move up and down, left and right, and links to each other exhaust device 40 with hot drill adsorber 10, Described hot drill adsorber 10 comprises adsorption plate 11, sealing ring 13 and sealing cover 14, and described adsorption plate 11 is provided with some adsorption holes 12, and adsorption hole 12 runs through the upper and lower surface of adsorption plate 11, and adsorption hole 12 The pore size jumps into two stages, and the pore diameter Φ2 close to the adsorption hole 12 on the upper surface is smaller than the pore diameter Φ1 near the adsorption hole 12 on the lower surface of the adsorption plate 11; 11 is sealed and connected, and the sealing ring 13 surrounds all the adsorption holes 12 in the space enclosed by the sealing ring 13; the sealing cover 14 is arranged a...

Embodiment 2

[0025] like image 3 , 4 , 5, the aperture Φ2 is greater than or equal to the outer diameter of the bottom of the hot drill, and the aperture Φ1 is smaller than the outer diameter of the bottom of the hot drill. The height H of the adsorption hole 12 with a diameter of Φ2 is less than the height of the hot drill and greater than half of the height of the hot drill. This embodiment is to solve the problem that if it is the top of the hot drill instead of the bottom of the hot drill that first enters the adsorption hole 12, it can be easily removed from the adsorption hole 12, and then re-adsorbed, so that the bottom surface of the hot drill first into the adsorption hole 12 to realize the sealing of the adsorption hole 12.

[0026] If the top surface of the hot drill has entered in the adsorption hole 12, the height H of the adsorption hole 12 with a diameter of Φ2 is less than the height of the hot drill and greater than half of the height of the hot drill, so that the botto...

Embodiment 3

[0028] like figure 1 As shown, the present embodiment improves the activity mode of the hot drill adsorber 10 . Described movable device comprises telescopic cylinder 20 up and down and moving screw mandrel 30 left and right, hot drill absorber 10 is arranged on the telescopic cylinder 20 up and down, described telescopic cylinder 20 is arranged on the screw mandrel 30 that moves left and right, and the screw mandrel that moves left and right 30 is connected with screw driver 31.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com