U-shaped clamping block for locking mechanical arm cables in intelligent workshops

A technology of manipulators and clamping blocks, applied in the field of U-shaped clamps for cable locking of manipulators in intelligent workshops, can solve the problems of short circuit or electric leakage, inconvenient work of manipulators, and inability to connect well at wiring, etc. Insulation, the effect of improving point-to-point efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

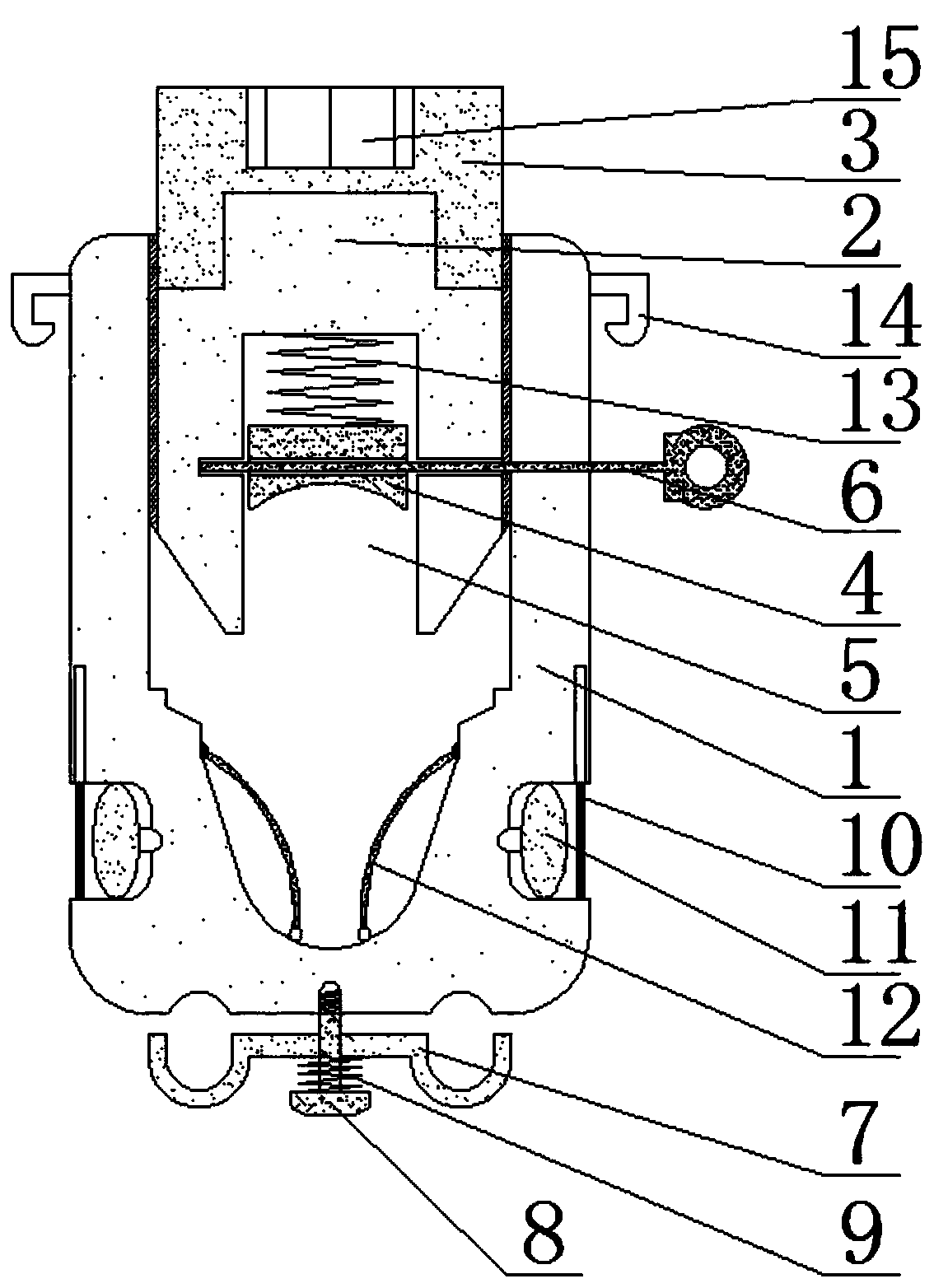

[0024] like figure 1 As shown, a U-shaped clamp block for locking cables of manipulators in intelligent workshops designed by the present invention includes a clamp body 1 and a threaded block 2 installed in the opening groove of the clamp block. The middle part of the threaded block 2 is provided with Circular groove 5, the top block 4 for clamping the cable joint is installed in the circular groove 5, the space in the opening groove of the clamp body is adjusted through the cooperation of the clamp body 1 and the threaded block 2, and two sections of cables are clamped by the top block 4 The top of the threaded block 2 is integrally equipped with an insulating cover 3, and the middle part of the insulating cover 3 is provided with a hole 15 for adjusting the connection state of the threaded block and the clamping block body. The hole 15 is an inner hexagonal groove, which is convenient Use a wrench to adjust the threaded block 2, and the top of the clamp body 1 is also equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com