Double-layer anti-pressure acrylic floor

An acrylic, double-layer technology, applied in the direction of elastic floor, floor, building, etc., can solve the problem of insufficient load-bearing and compressive capacity of acrylic board, and achieve the effect of preventing damage, improving service life and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

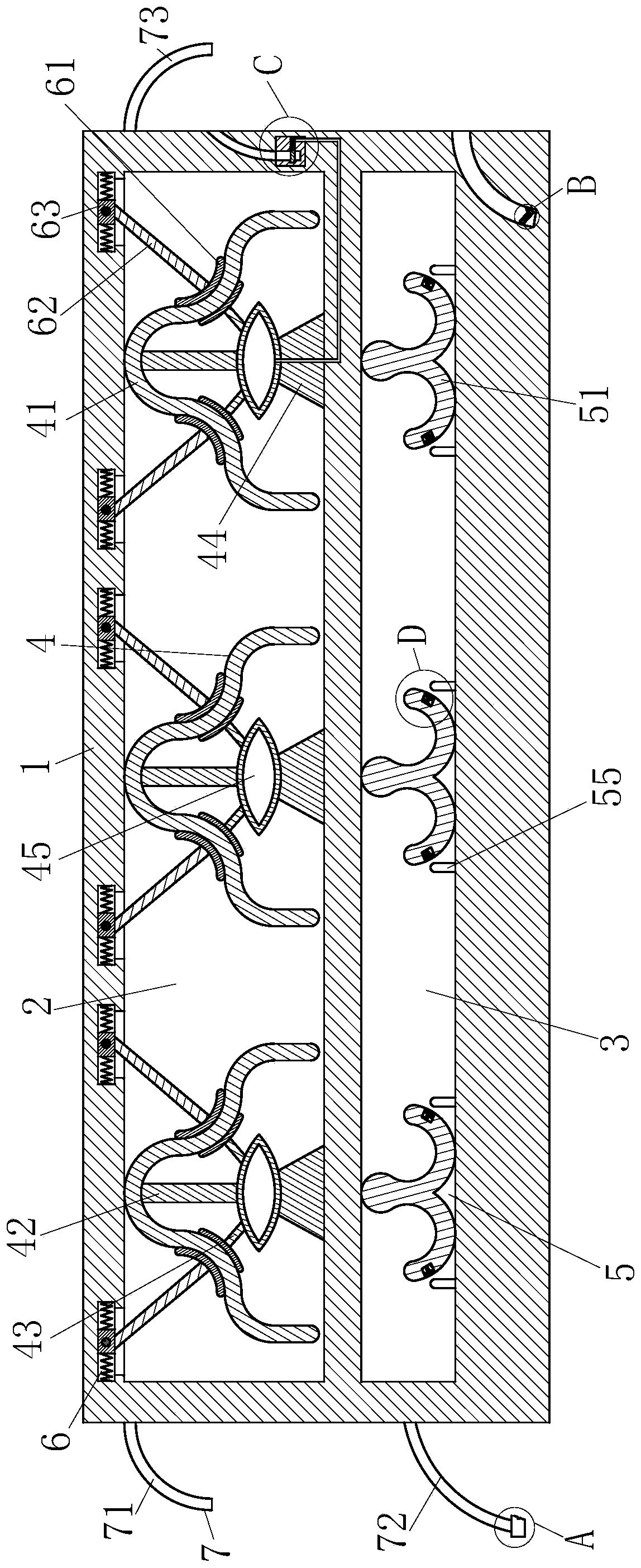

[0022] use Figure 1-Figure 7 A double-layer pressure-resistant acrylic floor according to an embodiment of the present invention is described as follows.

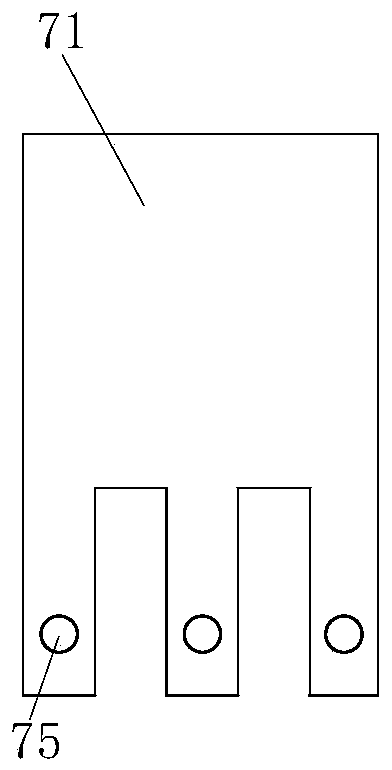

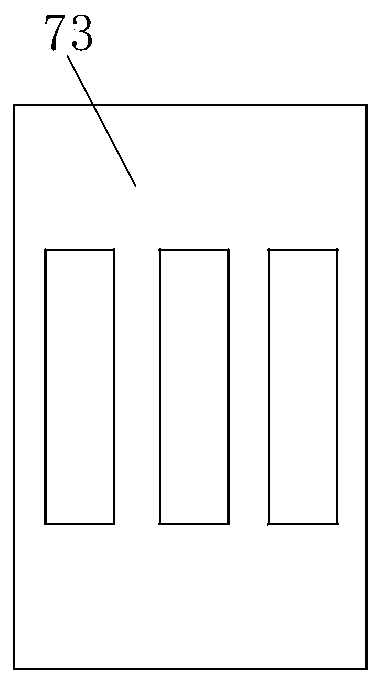

[0023] like Figure 1-Figure 7 As shown, a double-layer pressure-resistant acrylic floor according to the present invention includes a main body 1, a first cavity 2, a second cavity 3, a component force mechanism 4, a buffer support mechanism 5, a sliding protection mechanism 6 and an installation Mechanism 7; the force component mechanism 4 is arranged in the first cavity 2, and the force component mechanism 4 includes a convex cover plate 41, a first support rod 42, a second support rod 43, a third support rod 44 and a metal elastic frame 45; The convex cover plate 41 is provided with three, and the upper end of the inner wall of the convex cover plate 41 is fixedly connected with the first support rod 42; the lower end of the first support rod 42 is fixedly connected to the upper surface of the outer end of the metal e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com