Highly waterproof photovoltaic cable

A photovoltaic cable and performance technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of insufficient softness and limited waterproof performance, and achieve the effect of improving softness and waterproofing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

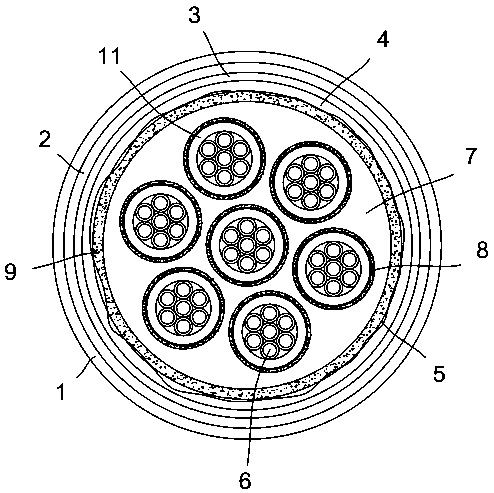

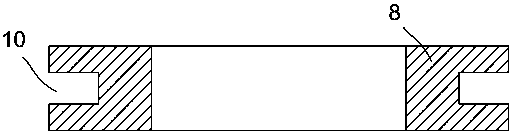

[0016] Such as figure 1 As shown, the photovoltaic cable with high waterproof performance includes a protective layer 1, a shielding layer 2, a waterproof layer 3, an insulating layer 4, a flexible protective layer 5, a cable core 6, and a connecting frame 7. There are multiple cable cores 6, and the cable core 6 is wrapped with an isolation layer 11, and there are multiple connecting skeletons 7 arranged at equal intervals along the length of the cable. Each connecting skeleton 7 is provided with the same number of perforations as the cable core 6, and the number of perforations is equal to that of the cable core 6. Not intersecting, each of the perforations is provided with a rubber pad 8 along the inner peripheral surface, the connecting skeleton 7 is sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com