Taxus anti-bacterial and mite-proof pillow inner

A technology of yew and pillow core, which is applied in the field of bedding, can solve the problems of poor air permeability, hotness of consumers, and poor antistatic performance, and achieve the effects of maintaining humidity and temperature, improving softness, and antistatic hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

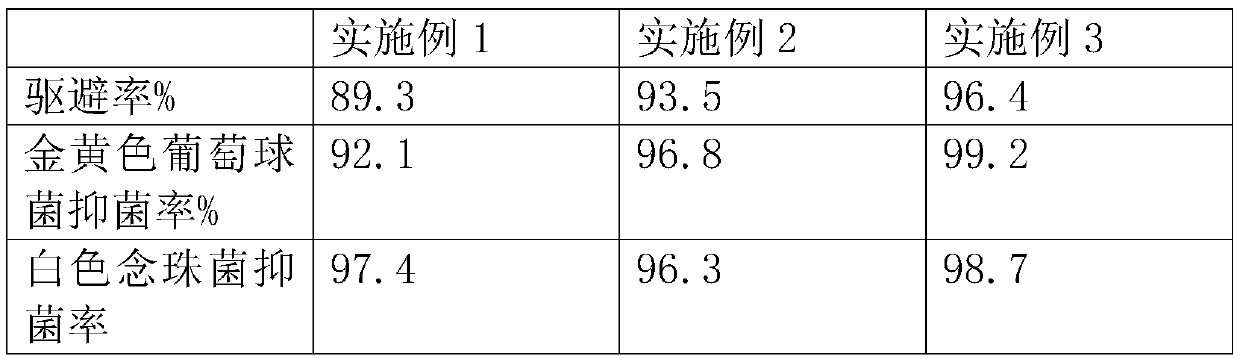

Embodiment 1

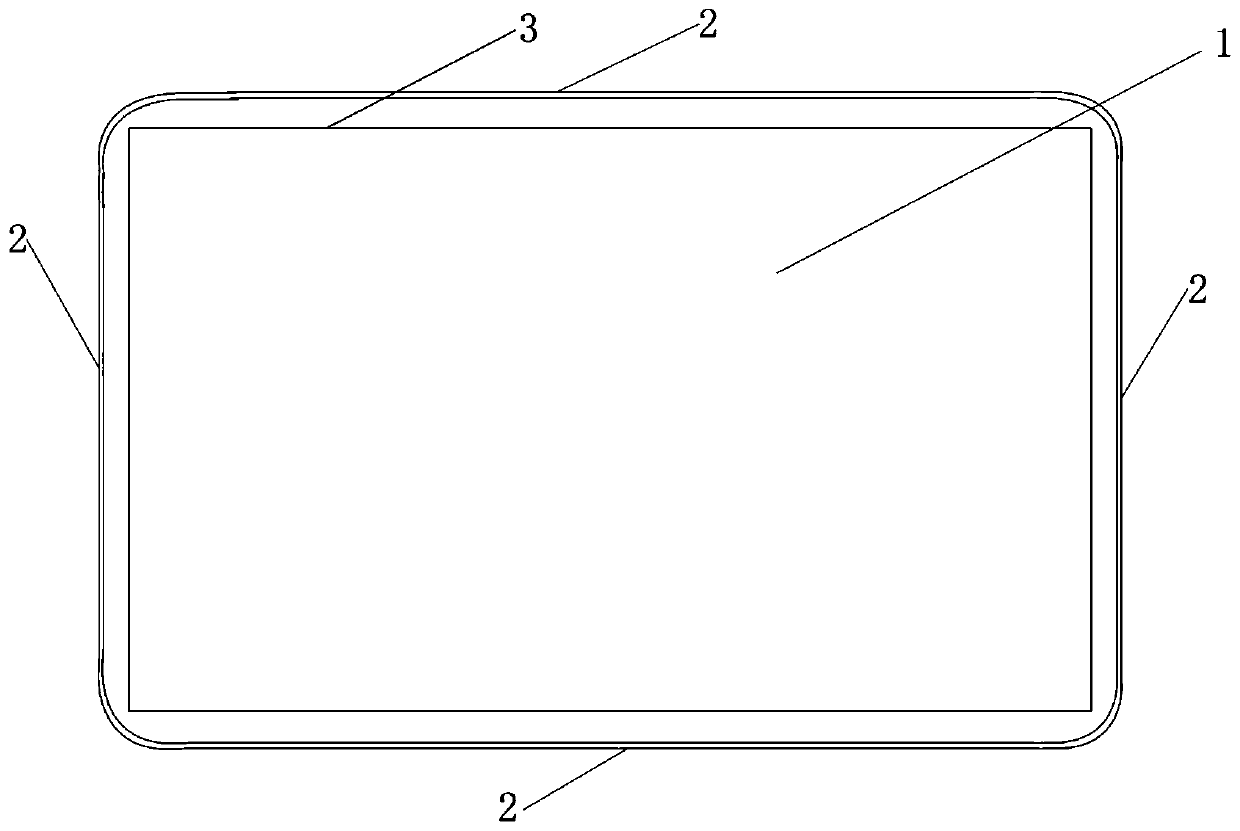

[0025] Such as figure 1 Shown: a yew antibacterial and anti-mite pillow, including a pillow top layer 1 and a pillow bottom layer, the pillow top layer 1 and the pillow bottom layer are sewn into a cavity, and the pillow top layer 1 and the pillow bottom layer are quilted 2 Wrap the filling layer 3; by weight percentage, the filling layer 3 includes blended fibers; the blended fibers include 80% yew fibers and 20% polyester fibers; the pillow surface layer and the pillow bottom layer are made of antibacterial Pure cotton fabrics with a percentage greater than 60%.

[0026] The preparation method of blended fiber, comprises the following steps:

[0027] 1) Cut the raw material of yew into 3-5cm long tablets with a diameter of 3-4cm, rinse the tablets in hot water at 40°C for 20 minutes to fully wash away the silt and sawdust contained in the tablets other impurities;

[0028] 2) Place the tablet in lye for cooking, the lye is sodium hydroxide solution, the cooking temperatur...

Embodiment 2

[0034] A yew antibacterial and anti-mite pillow core comprises a pillow surface layer and a pillow bottom layer, and the pillow surface layer and the pillow bottom layer are sewn into a cavity, and the cavity includes a filling layer; in weight percentage, the filling layer includes blended fibers; the blended fibers It includes 85% yew fiber and 15% polyester fiber; the pillow top layer and pillow bottom layer are made of pure cotton fabric with a bacteriostatic rate greater than 60%.

[0035] The preparation method of blended fiber, comprises the following steps:

[0036] 1) Cut the yew raw material into 3-5cm long and 3-4cm in diameter tablets, rinse the tablets in hot water at 50°C for 20 minutes to fully wash away the silt and sawdust contained in the tablets other impurities;

[0037] 2) Place the tablet in lye for cooking, the lye is sodium hydroxide solution, the cooking temperature is 135°C, the cooking time is 2.5h, and the concentration ratio of the tablet is 0.5g / ...

Embodiment 3

[0043] A yew antibacterial and anti-mite pillow core comprises a pillow surface layer and a pillow bottom layer, and the pillow surface layer and the pillow bottom layer are sewn into a cavity, and the cavity includes a filling layer; in weight percentage, the filling layer includes blended fibers; the blended fibers It includes 90% yew fiber and 10% polyester fiber; the pillow top layer and pillow bottom layer are made of pure cotton fabric with a bacteriostatic rate greater than 60%.

[0044] The preparation method of blended fiber, comprises the following steps:

[0045]1) Cut the yew raw material into 3-5cm long and 3-4cm in diameter tablets, rinse the tablets in hot water at 60°C for 30 minutes to fully wash away the silt and sawdust contained in the tablets other impurities;

[0046] 2) Place the tablet in lye for cooking, the lye is sodium hydroxide solution, the cooking temperature is 140°C, the cooking time is 3h, the concentration ratio of the tablet is 0.5g / ml; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com