Focusing system for antenna feed source

An antenna feed source and feed source technology, which is applied in the direction of antenna, antenna support/installation device, antenna grounding switch structure connection, etc., can solve the problems of increasing construction time, high weight, and prolonging construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

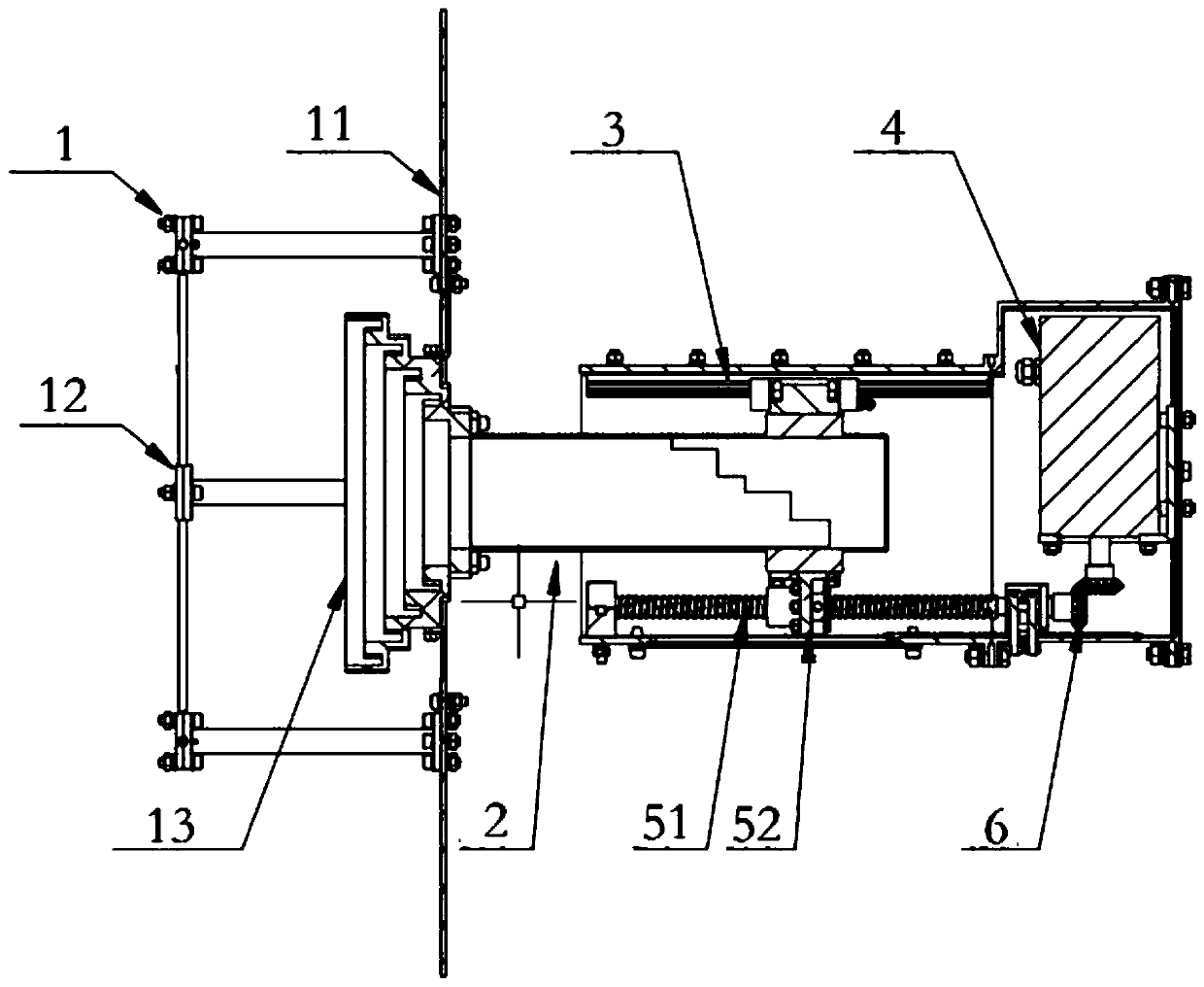

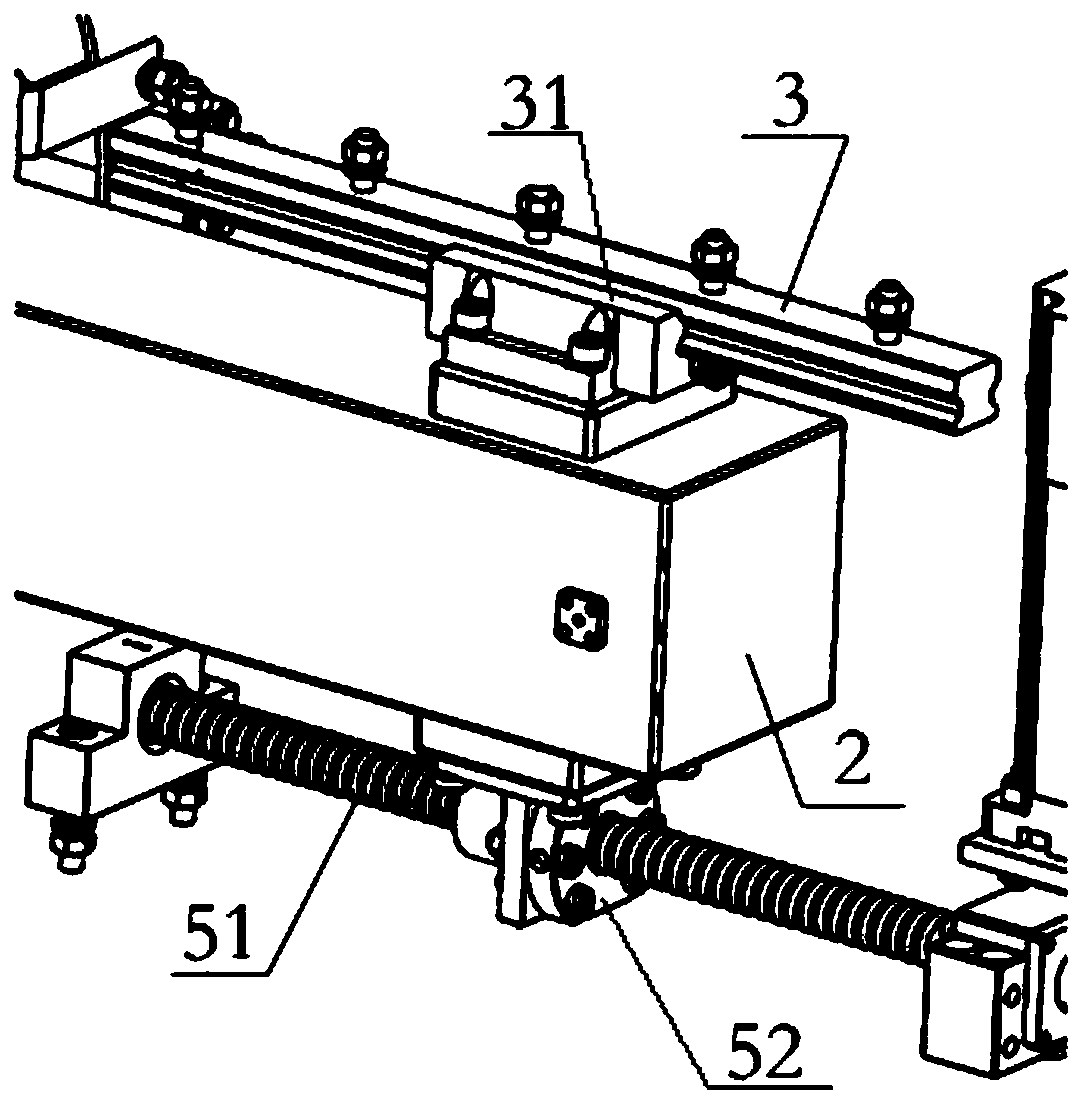

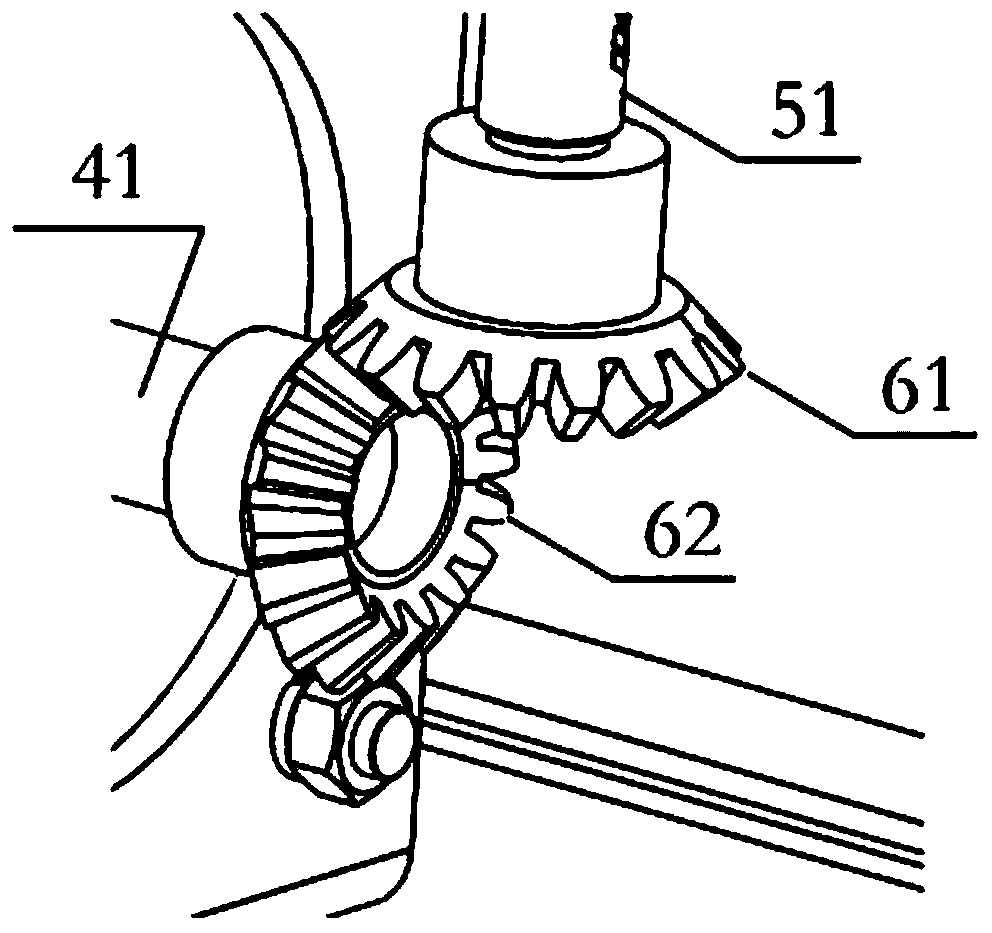

[0023] In this exemplary embodiment, a focusing system for an antenna feed is firstly provided, refer to figure 1 As shown, it mainly includes: a feed source 1, a waveguide 2, a linear guide rail 3, a lead screw 51, a driving motor 4, and the like.

[0024] Specifically, the front end of the waveguide 2 is provided with a feed source, refer to figure 1 , Figure 4 As shown, the feed source 1 includes a reflective surface 11 arranged at the front end of the waveguide 2 , and a horn feed 13 and a symmetrical oscillator feed 12 arranged on the reflective surface 11 . The feed part integrates the symmetrical vibrator array feed 12 suitable for lower frequency bands such as high frequency and very high frequency, and the horn feed source 13 suitable for higher frequency bands suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com