Target stand device for laser-driven micro-debris experiments

A technology of laser drive and target frame, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve the problems of difficult to adjust the size of the spot, low precision of the impact position, and inability to monitor in real time, so as to facilitate observation and improve Accuracy, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The target holder device for the laser-driven micro-debris test of the present invention will be described in detail below with reference to the accompanying drawings, but this description is only exemplary and is not intended to limit the protection scope of the present invention.

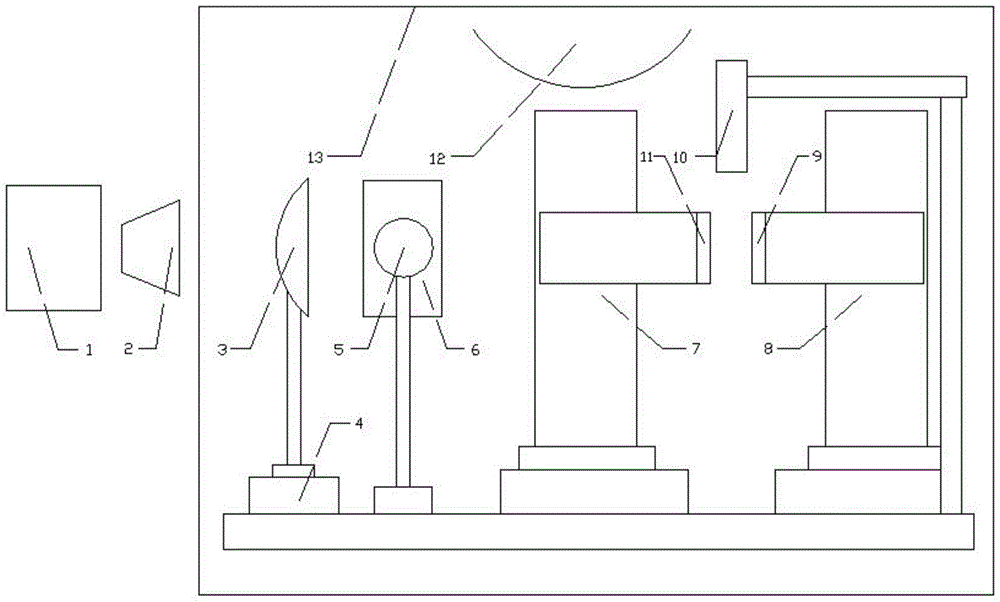

[0018] refer to figure 1 , figure 1 It is a schematic diagram of the target frame device used in the laser-driven micro-debris test of the present invention. Wherein the device comprises a laser 1, a beam expander 2 and a focusing lens 3, a beam splitter 6, a flyer target 11, an impact target 9 and a speed measurement system arranged in a vacuum tank; a focus lens 3, a flyer target 11 and an impact target 9 is coupled to the lower target frame and connected to the stepping motor, and the external controller is connected to the stepping motor through a cable to accurately control the positions of the focusing lens 3, the flyer target 11 and the impact target 9 on the target frame, and the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com