Anti-dislocation device for vulcanizing machine forming mold

A technology for forming molds and vulcanizers, applied in the field of vulcanizer equipment, can solve problems such as the position of the intermediate plate mold being pushed out of place, the failure of hot-melt molding of rubber workpieces, and the increase of waste of raw materials, so as to improve production efficiency and avoid hot-melt molding. Failure and mold damage, low implementation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

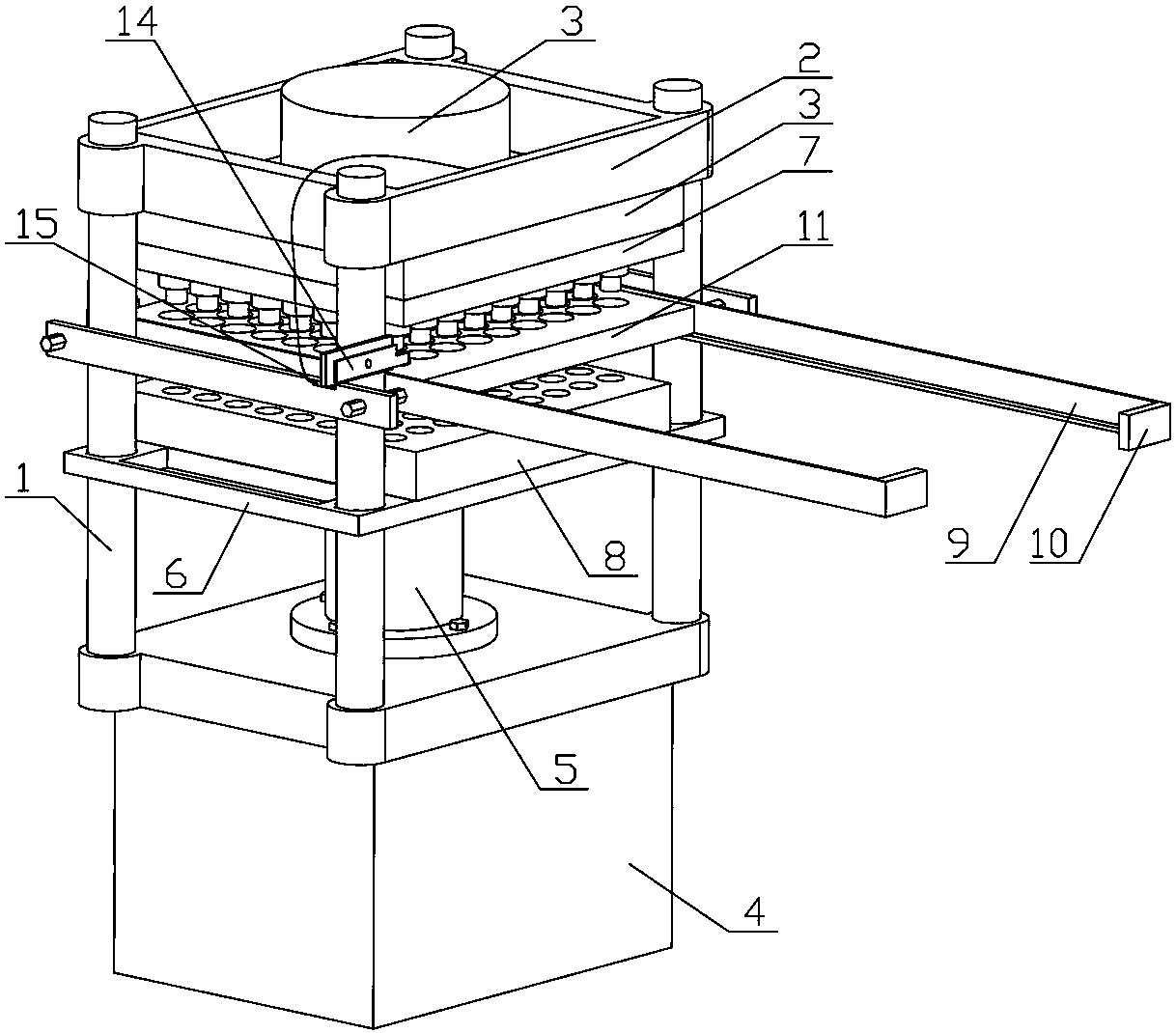

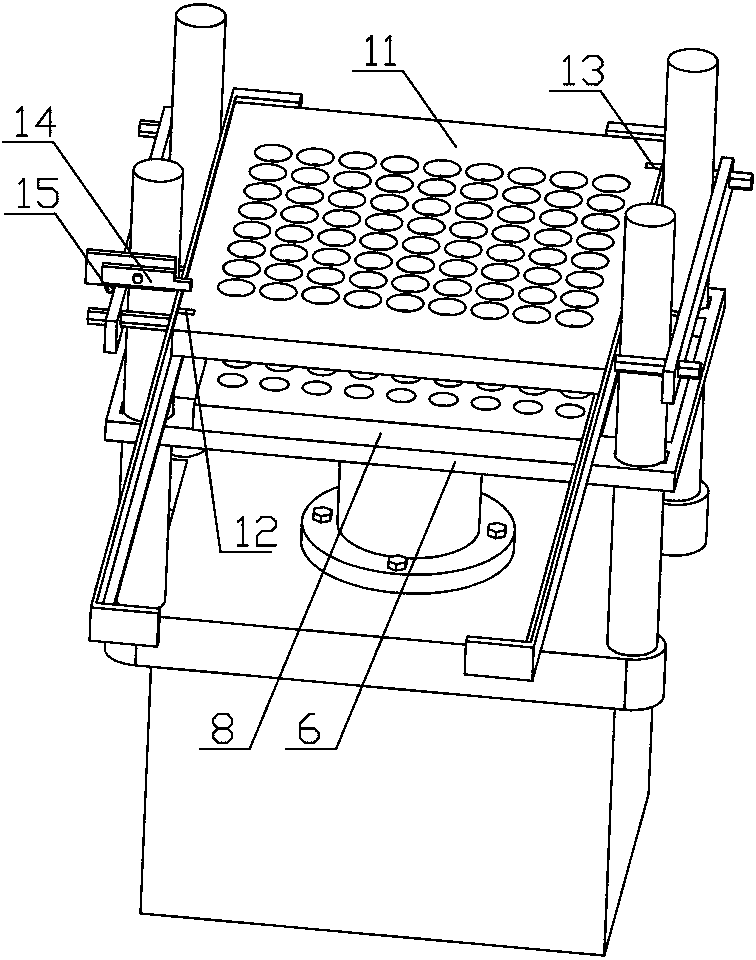

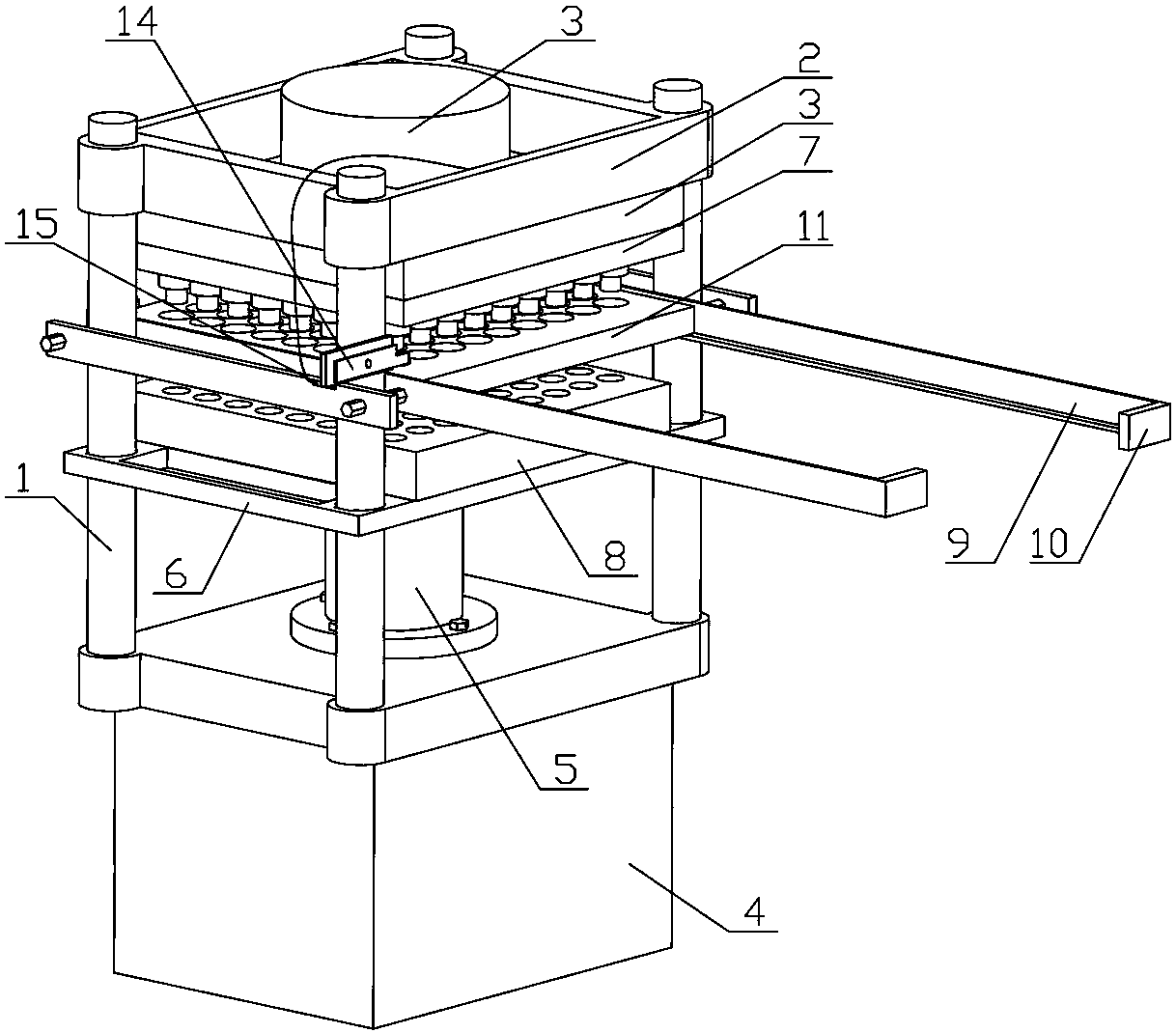

[0020] In this embodiment, an anti-displacement device for molding molds of a vulcanizing machine, the vulcanizing machine has four rectangular guiding columns 1 arranged side by side evenly, a cover 2 is installed on the upper end of the guiding columns 1, and the bottom of the cover 2 is installed There is a heating body 3, a base 4 is installed at the lower end of the guide column 1, and a lifting platform 6 that can move up and down along the guide column 1 is installed on the base 4 through a jacking hydraulic cylinder 5;

[0021] In this embodiment, the upper plate mold 7 and the bottom plate mold 8 for forming the workpiece are fixedly installed on the bottom of the heating body 3 and the lifting platform 6 table, respectively, and the guide column 1 between the upper plate mold 7 and the bottom plate mold 8 Two L-shaped guide rods 9 arranged horizontally side by side are fixedly installed on the inner side. Limiting flanges 10 are provided at both ends of each L-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com