Solenoid valve having adjustable spring force

A solenoid valve and valve sealing technology, which is applied in the field of solenoid valves with adjustable elastic force, can solve the problems of bolt tilt, high cost, troublesome bolt installation, etc., and achieve increased surface pressure, simple assembly, and long-lasting force transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

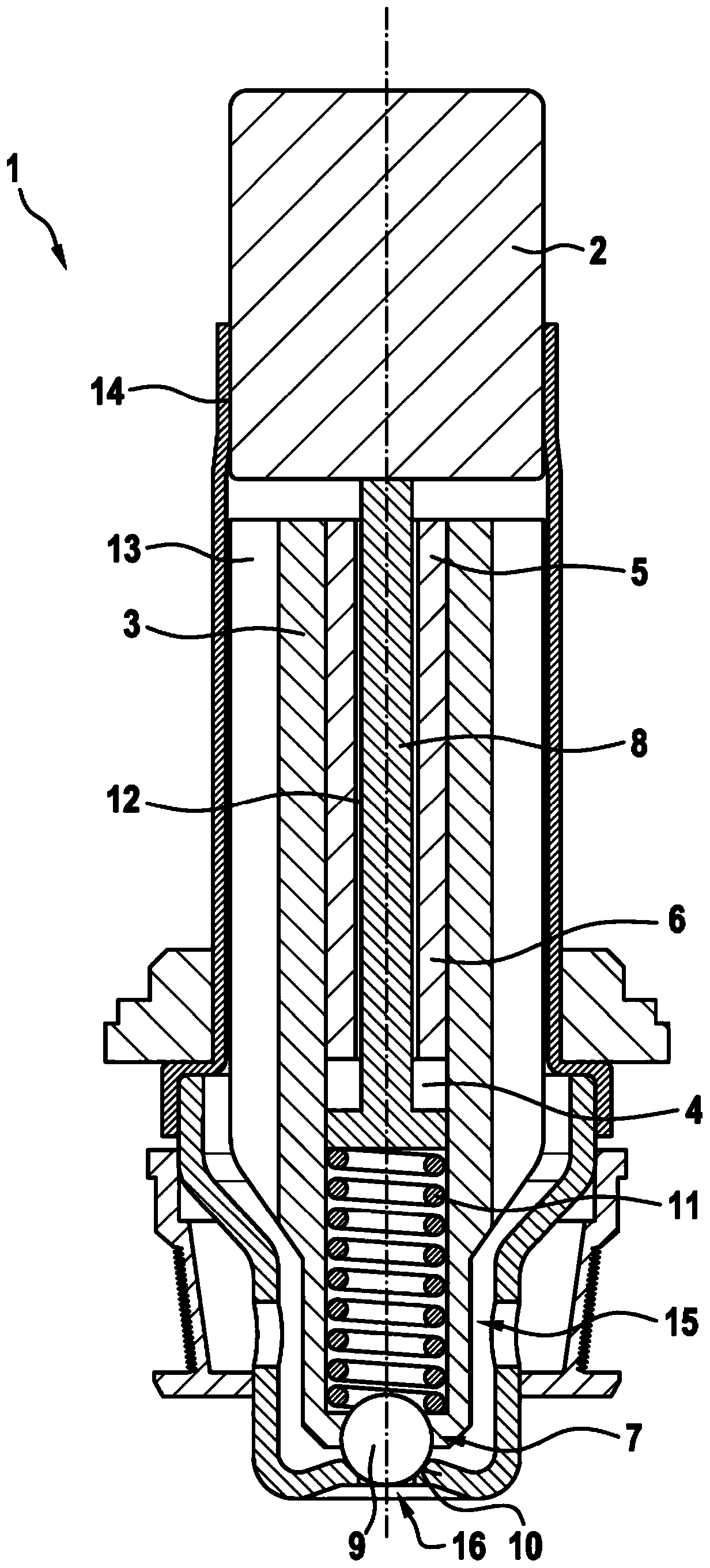

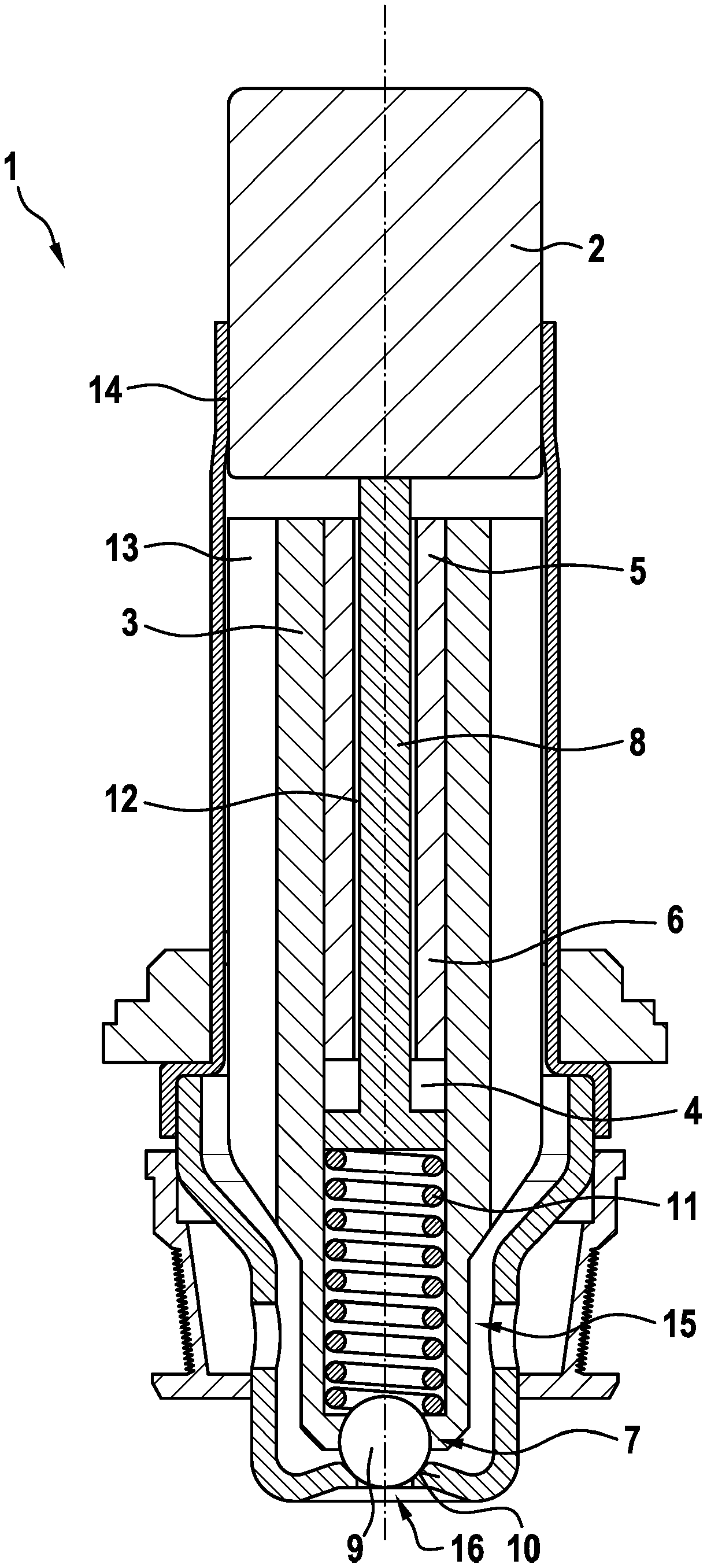

[0034] figure 1 A solenoid valve 1 for a brake system of a motor vehicle is shown in longitudinal section. The solenoid valve 1 comprises a housing 14 which is designed as a cylindrical sleeve and in which a likewise cylindrical armature 3 is arranged longitudinally or axially displaceable. Assigned to the upper end of the armature 3 is the pole core 2 connected in series or arranged with the armature 3 and locked in the housing 14 , for example by means of a welded connection. A valve body 15 held by a housing 14 and having a throughflow opening 16 is assigned to the opposite lower end of the armature 3 . Furthermore, the valve body 15 is provided with a sealing seat 10 .

[0035] The armature 3 has an axial receptacle in the form of an axial passage 4 which extends centrally through the armature 3 . The axial passage 4 is tapered towards the lower end of the armature 3 so that the armature has a radially inwardly protruding projection 7 . A three-dimensional convex objec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com