Battery, carrier board, and carrier board element having locking elements

A locking element and carrier board technology applied to batteries. field, to achieve the effect of simple manufacturing technology and high current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

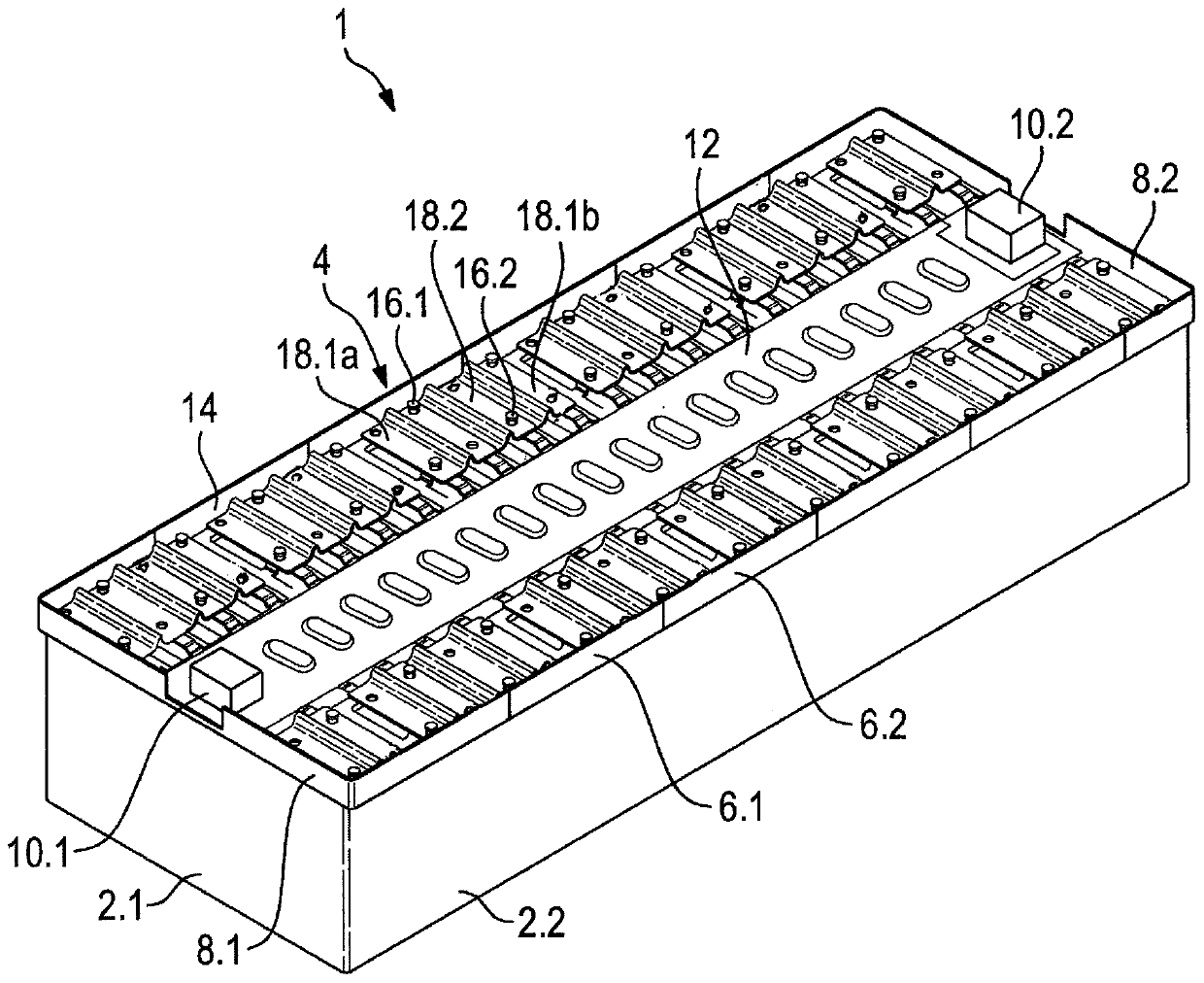

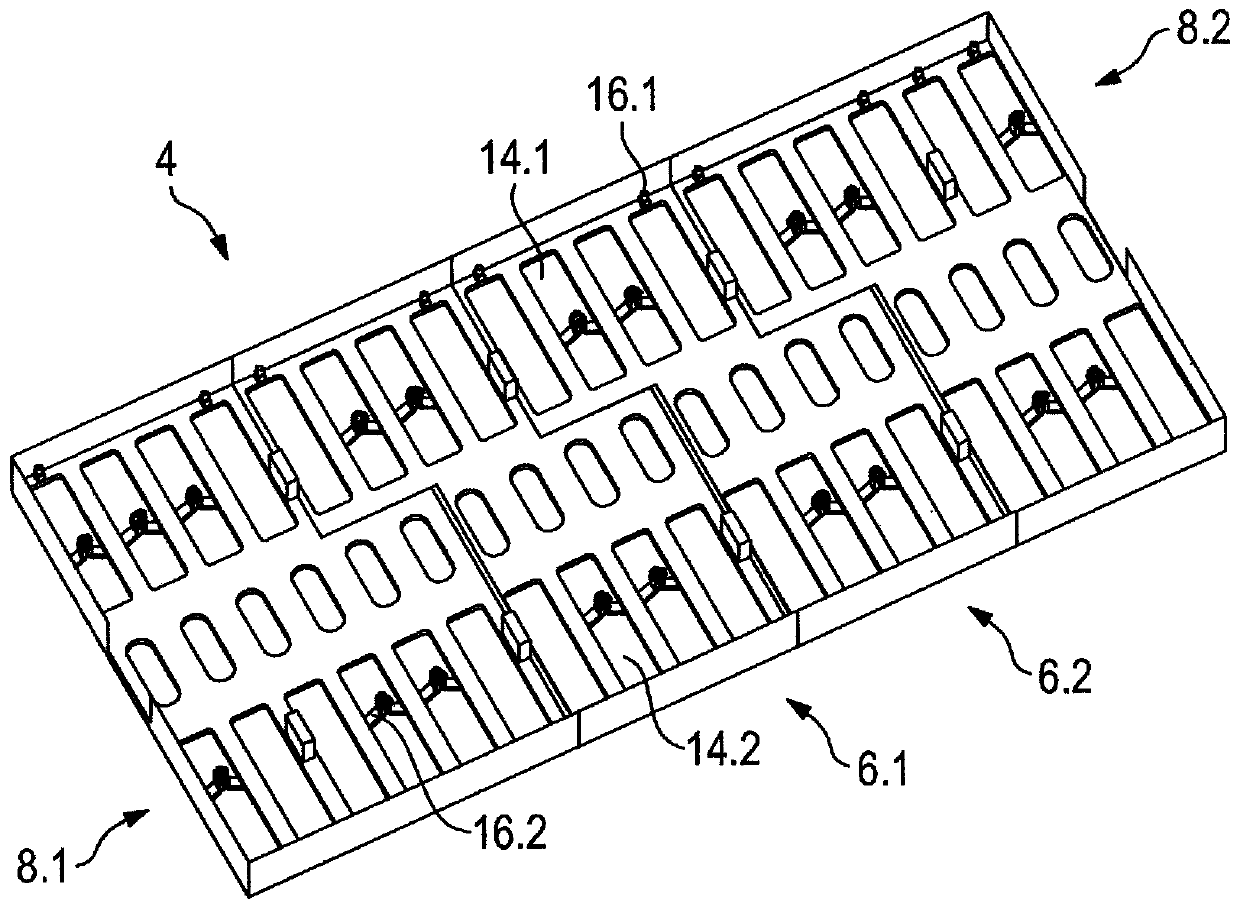

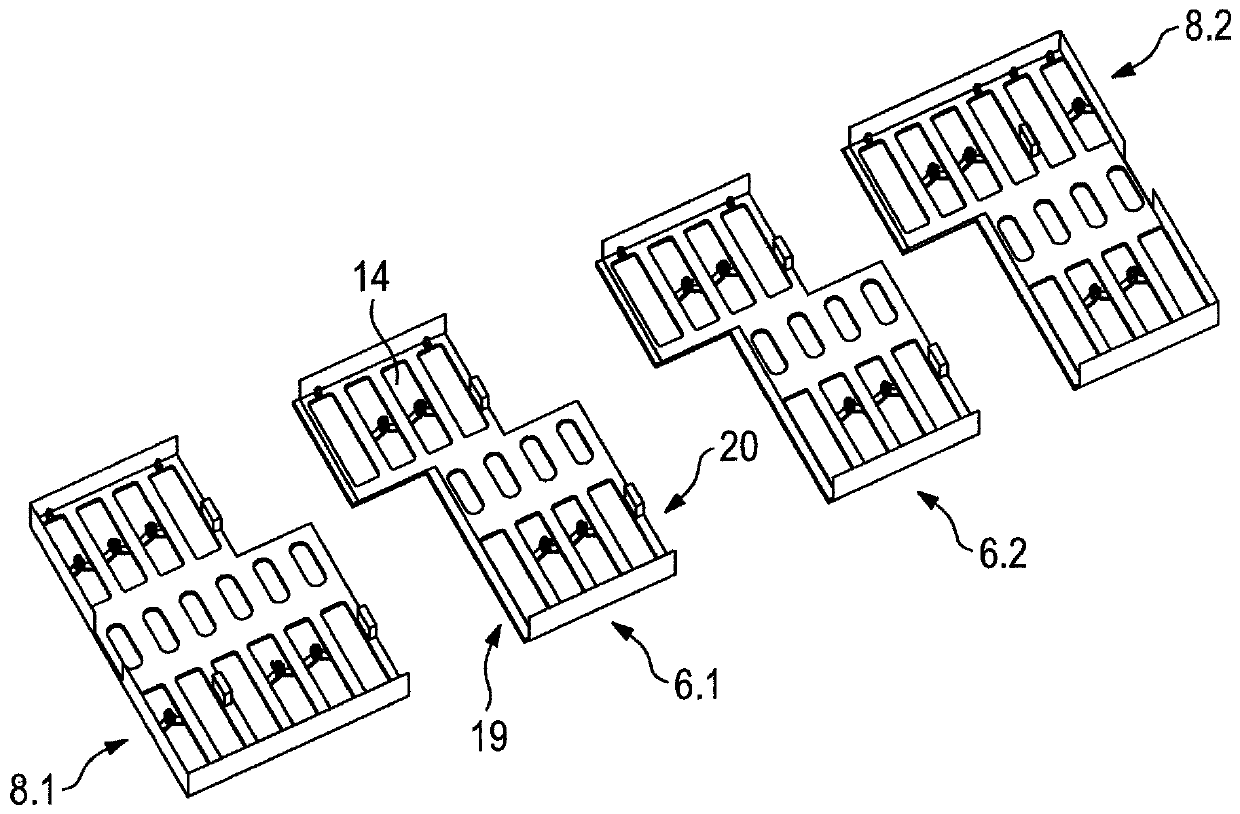

[0033] exist figure 1 A battery 1 with 22 battery cells 2 is shown in . The battery 1 has a carrier plate 4 consisting of a plurality (here four) of carrier plate elements 6 as well as a front current output element 8 . 1 and a rear current output element 8 . 2 .

[0034] In this embodiment, the battery 1 is provided with 11 strings and 2 parallel connections, that is, every two adjacent battery cells 2 are connected in parallel with each other, and 11 such adjacent battery cells connected in parallel are connected in series with each other. In other, not described, exemplary embodiments, a circuit of the same type with another number of battery cells or another number of battery cells connected in parallel to one another, as well as a purely series connection, are of course also conceivable.

[0035] Furthermore, the battery 1 has a power outlet socket 10 for connection to other batteries and / or power consumers.

[0036] On the carrier plate 4 and thus also on the individua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com