A miniature high-frequency heating power supply for quenching

A high-frequency heating and high-frequency technology, which is applied in the direction of quenching device, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of bulky, large volume, low efficiency, etc., and achieve the reduction of overall occupied space, saving investment cost, The effect of saving factory space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

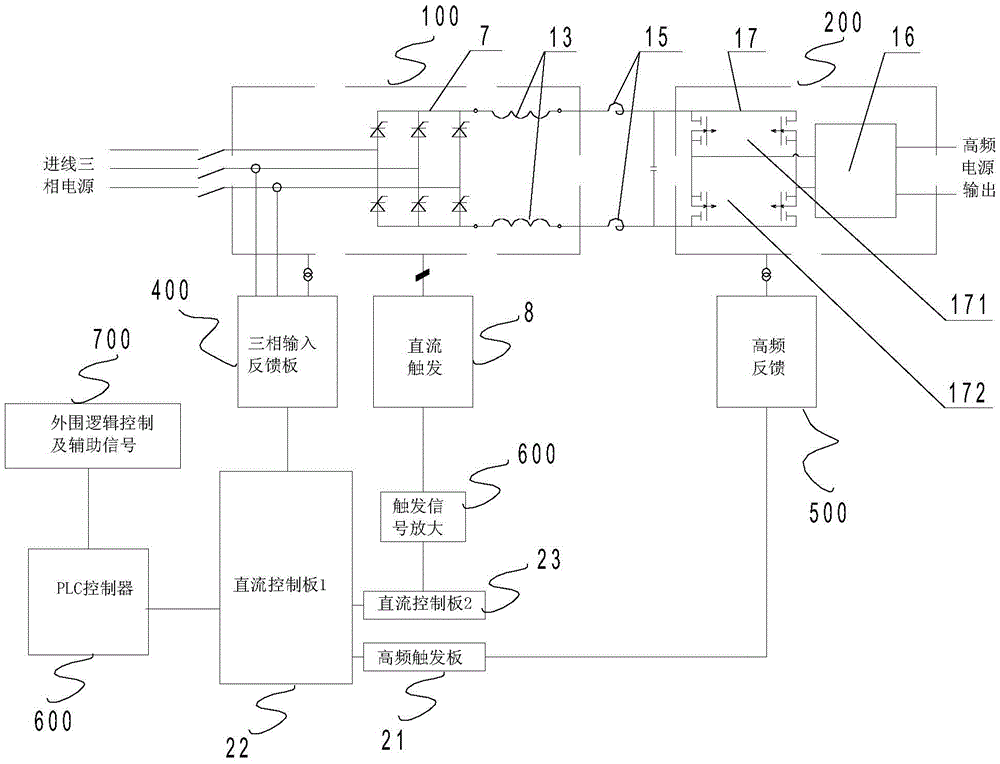

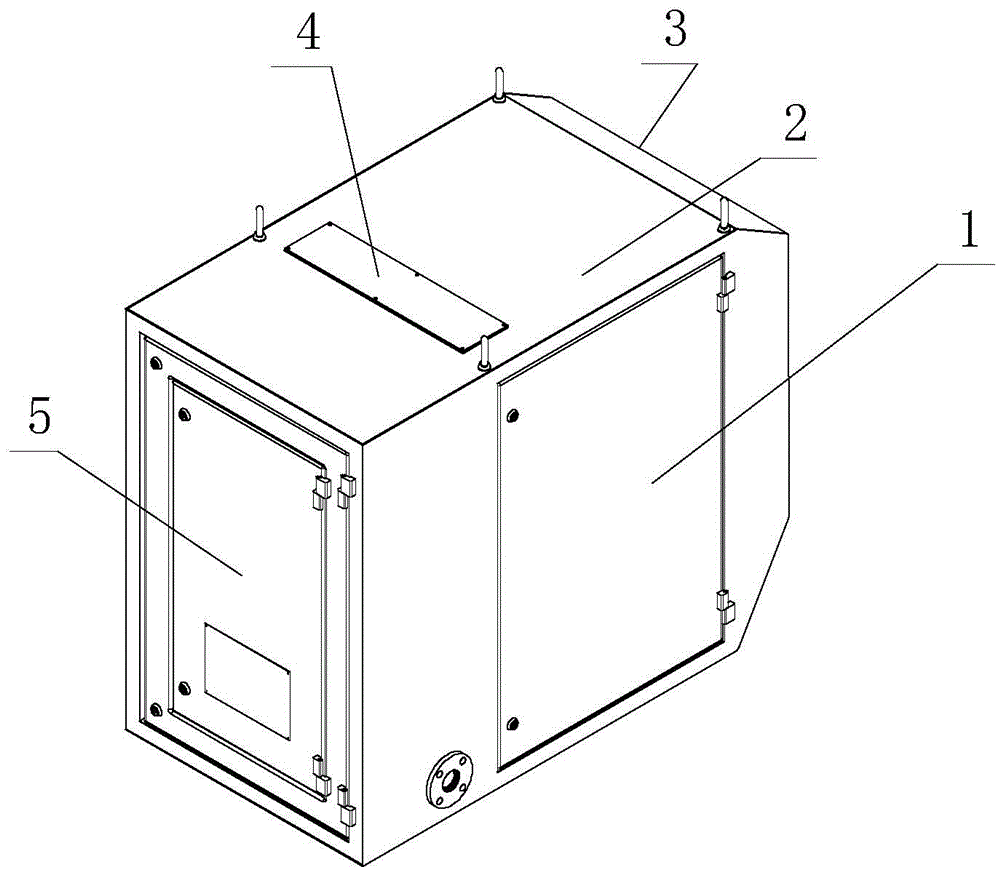

[0033] see figure 1 with figure 2 , the miniature high-frequency heating power supply for quenching of the present invention includes a rectification and voltage regulation system 100, a high-frequency resonance generation system 200 and a control system.

[0034] The rectification and voltage regulation system 100 includes a three-phase full-bridge rectifier bridge 7, two smoothing reactors 13, positive and negative balance coils 15 and a filter capacitor bank 27; , the negative output end in series; the positive and negative balance coils 15 are connected in series with the other ends of the two smoothing reactors 13 in one-to-one correspondence;

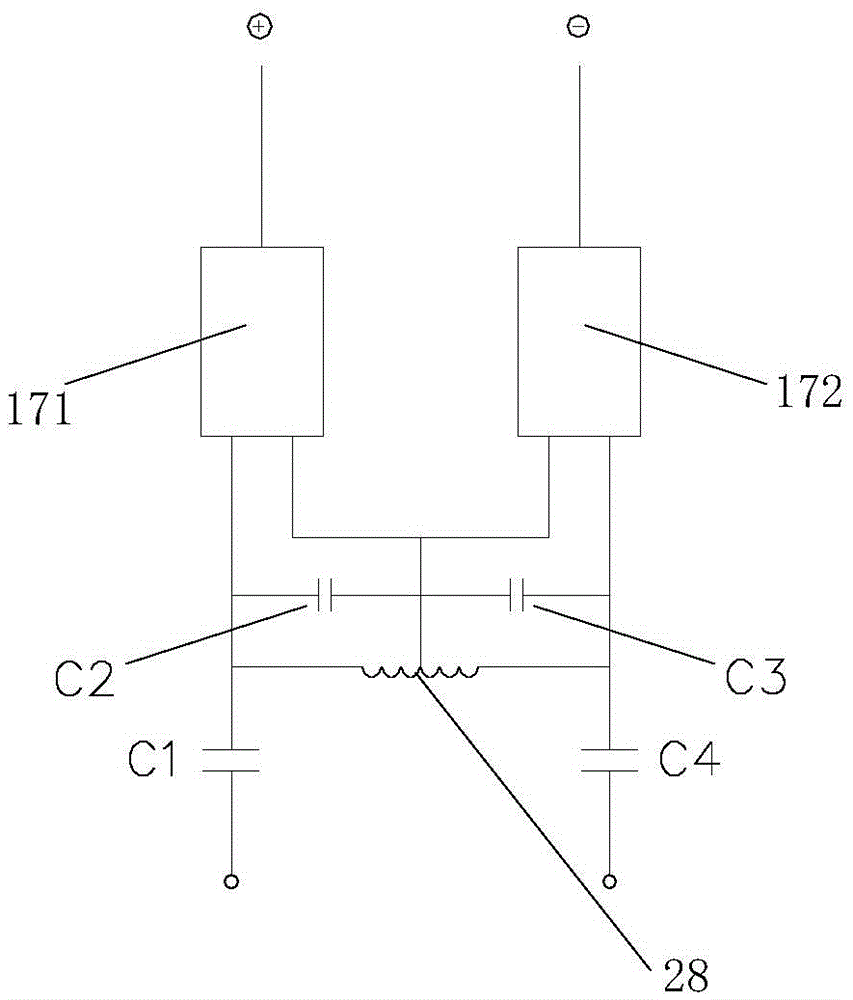

[0035] The high-frequency resonance generating system 200 includes a high-frequency power component 17 and a resonant capacitor tank 16; wherein, the high-frequency power component includes four MOSFET power devices, and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com