Plant frame

A plant rack and support rod technology, applied in the field of plant racks, can solve the problems of inconvenient storage of racks, time-consuming and laborious erection, moth-eaten, etc., and achieve the effects of suitable promotion, convenient construction and avoidance of decay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

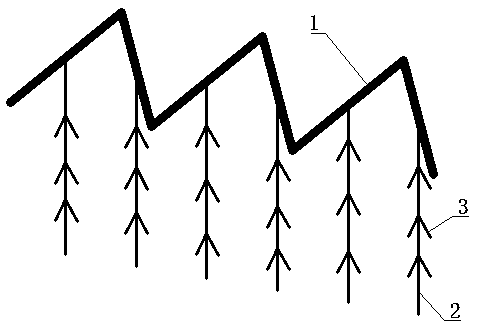

[0011] Such as figure 1 As shown, the plant stand includes a T-shaped support bar made of plastic material. The T-shaped support bar includes a horizontal bar 1 and a vertical bar 2. Several groups of straps 3 are arranged on the vertical bar 2 at intervals. The T-shaped support bar The quantity is 6-10, and one end of the horizontal bar 1 of a T-shaped support bar is hinged with one end of the horizontal bar 1 of another plant frame T-shaped support bar.

[0012] Preferably, the vertical rod 2 is fixedly connected with the middle part of the horizontal rod 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com