A cold start system for flexible fuel vehicles

A flexible fuel, cold start technology, applied in the charging system, fuel heat treatment device, engine starting and other directions, can solve the problems of fuel overheating, long heating time, high emissions, etc., to reduce power consumption, save production costs, The effect of reducing the warm-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

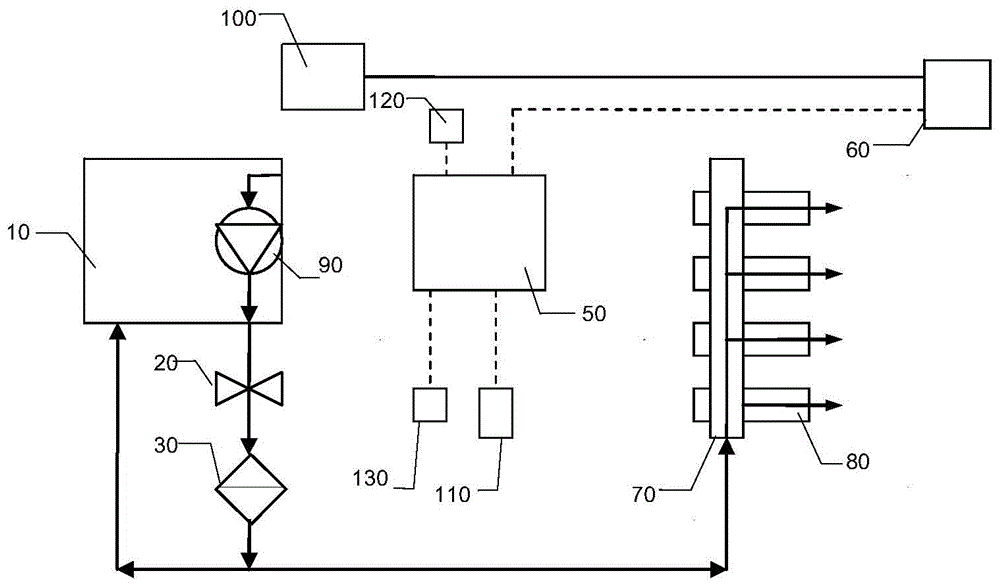

[0044] The cold start system includes fuel tank, heater, cold start signal light, preheating power module, water temperature sensor and engine fuel injector with heating function.

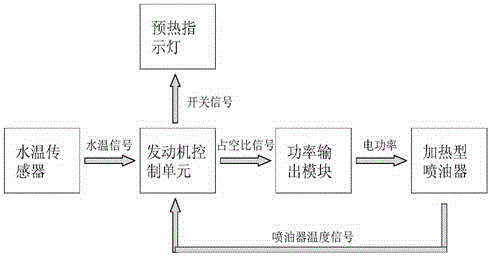

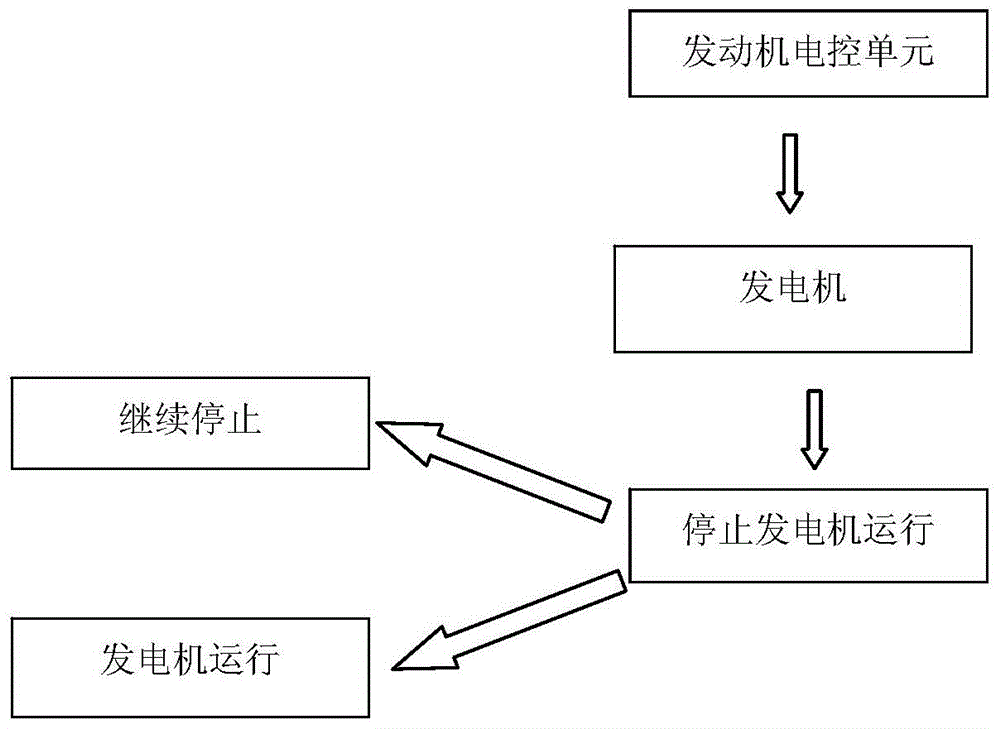

[0045] Such as Figure 5 As shown, the fuel preheating device is integrated with the engine injector, the preheating power module, the cold start signal light, the battery, and the key switch are connected in series in one circuit, and the engine electronic control unit ECU judges whether it is necessary to activate the device. When the temperature fed back by the water temperature sensor is below -15°C, the ECU will turn on and start the corresponding control strategy. When the key switch is turned off, the circuit is turned on, and the engine fuel injector with heating function will use the electric energy of the battery to raise its temperature above 180°C within 5 seconds, so that the injected fuel reaches 110°C and heats the air in the cylinder. To achieve the purpose of smooth ignition at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com