Movable lifting compact rack

A compact rack and mobile technology, applied in the field of compact racks, can solve the problems of injury of workers, insufficient stability of compact racks, and inability to adjust the baffle up and down, so as to reduce workload and work intensity, and improve convenience and safety. , the effect of promoting the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

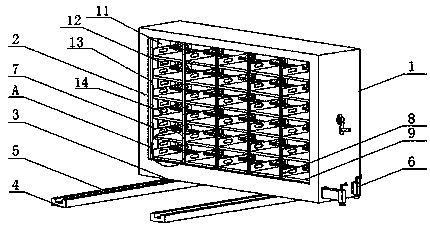

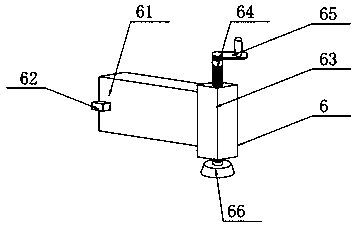

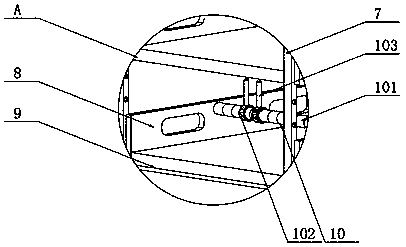

[0029] see Figure 1~4 , in an embodiment of the present invention, a mobile lifting compact shelf includes a compact shelf body 1, a guide rail sliding assembly, a support locking assembly 6, a partition 9, a hanging plate 8 and a column 7, wherein the compact shelf body 1 The bottom of the guide rail sliding assembly can slide and move along the extension direction of the guide rail sliding assembly. The support locking assembly 6 is arranged on the two sides of the guide rail sliding assembly on the compact shelf body 1, and the support locking assembly 6 pairs The compact shelf body 1 is supported so as to prevent it from sliding and moving on the guide rail sliding assembly, the compact shelf body 1 is provided with a plurality of partitions 9 arranged with adjustable vertical intervals, and it is characterized in that each The partitions 9 are arranged horizontally, and each of the partitions 9 is fixed with a plurality of hanging boards 8, and a plurality of parallel co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com