Surface spraying device for automobile lamp shell production

A technology for automotive lamps and surface spraying, applied in spraying devices, spray booths, etc., can solve the problems of unable to achieve standardized production, remediation of missing spraying, uneven spraying, etc., to achieve effective spraying surface, enhance production efficiency, spraying thoroughly uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. As a part of this specification, the principles of the present invention are explained through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same or similar components in different drawings are represented by the same reference numerals.

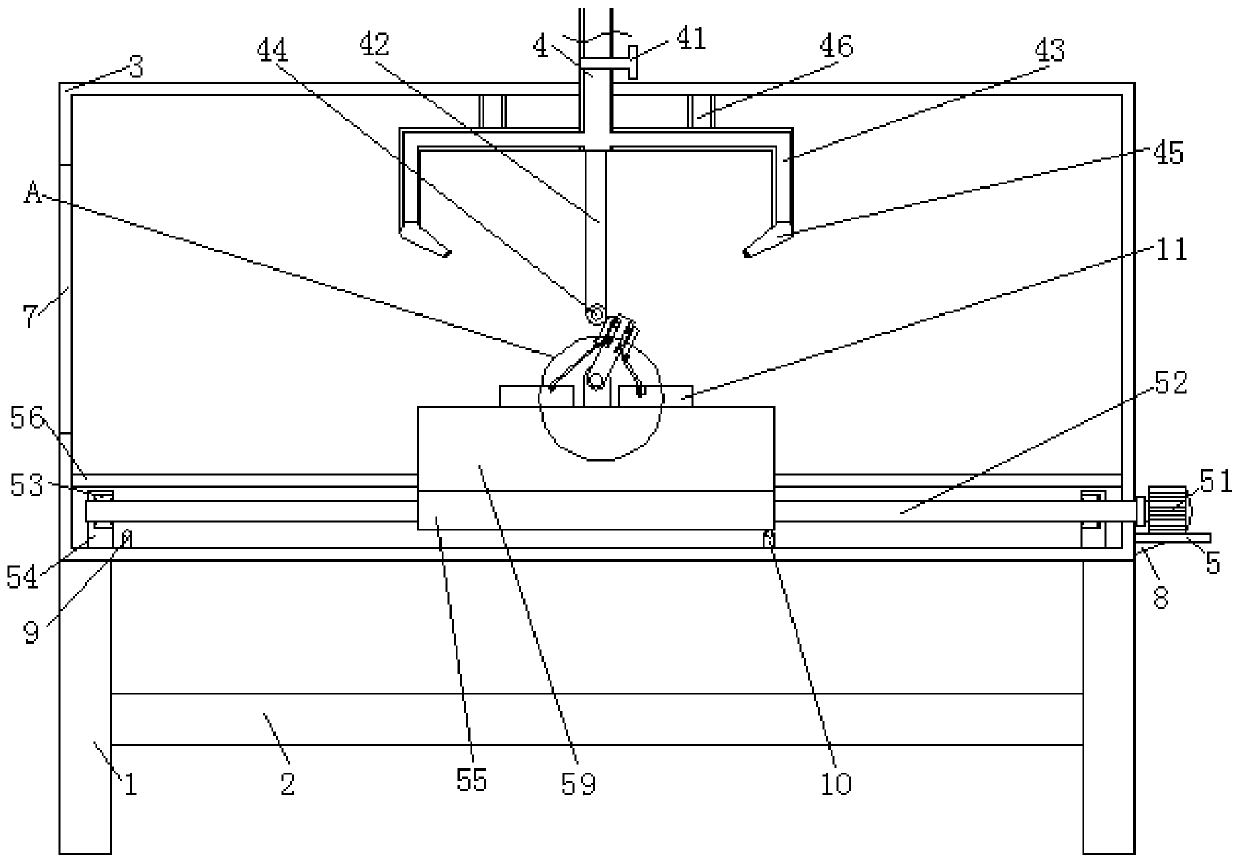

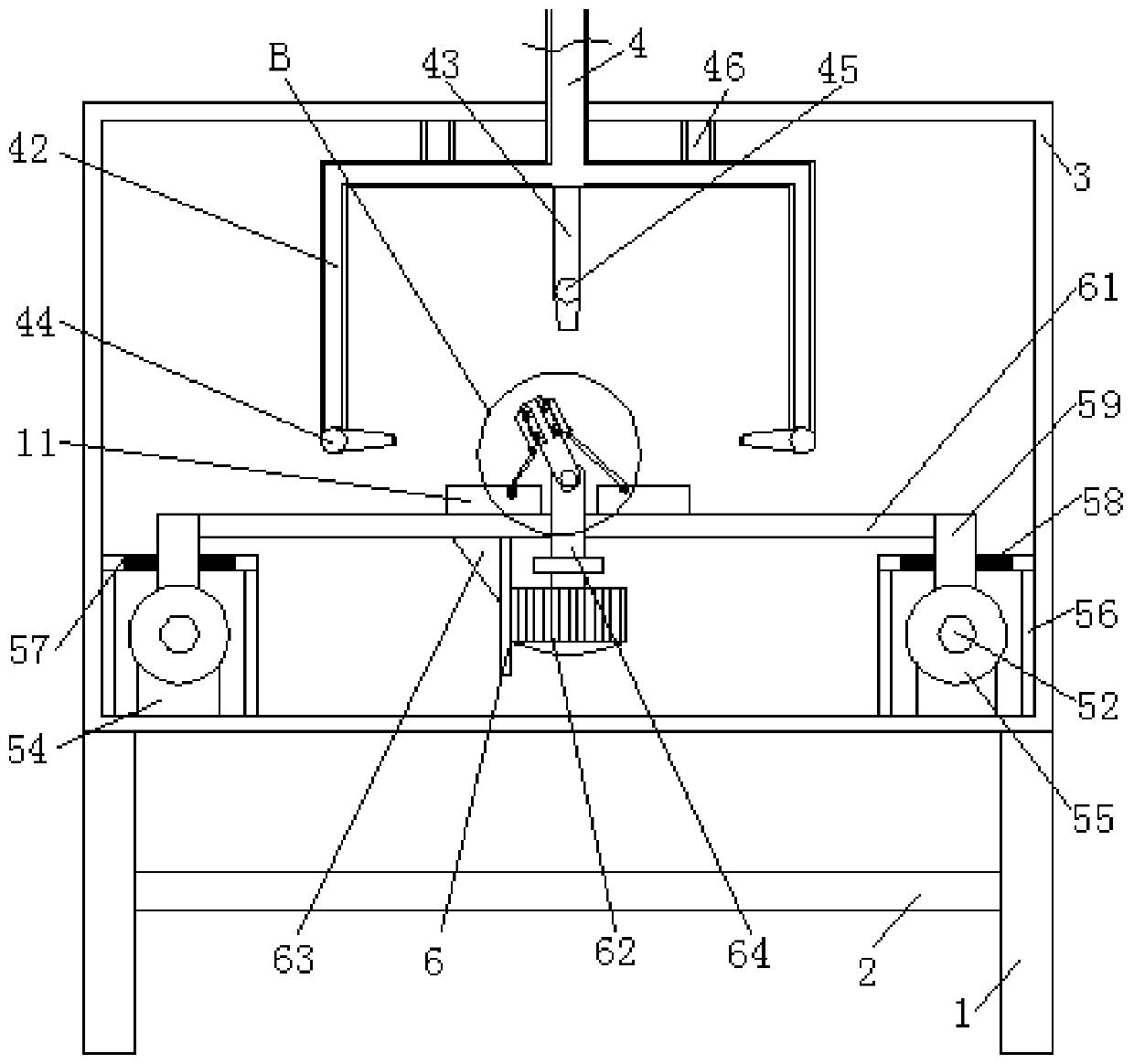

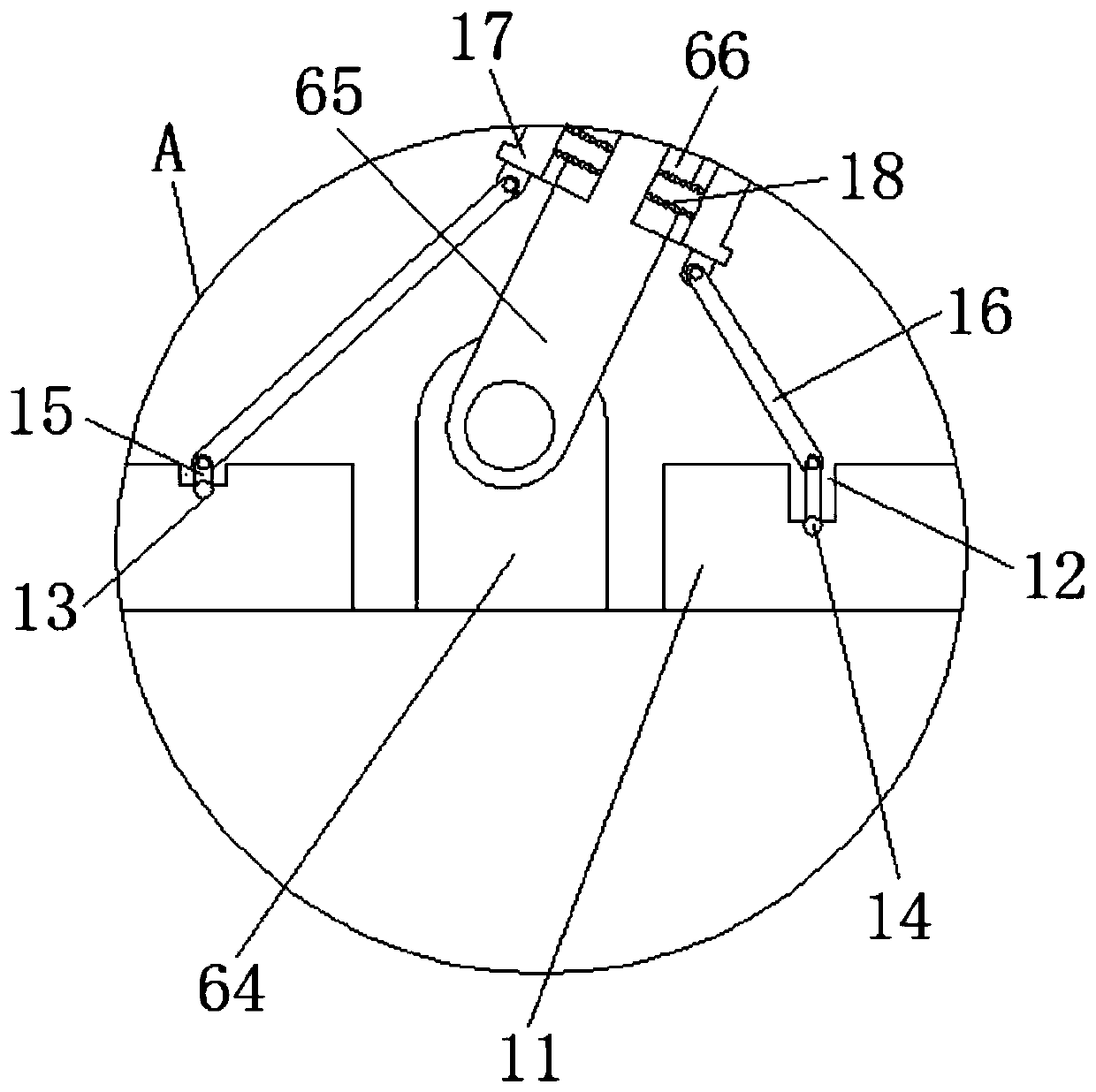

[0040] Such as Figure 1-4 As shown, the surface spraying device for automobile lamp shell production provided by the present invention includes a supporting leg 1, a reinforcing leg 2 is fixedly connected between the supporting legs 1, and a spraying frame 3 is fixedly connected to the top of the supporting leg 1, and the spraying frame 3 The door 7 is hinged, the material of the door 7 is tempered glass, the inner top wall of the spraying frame 3 is provided with a spraying mechanism, and the sprayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com