Method for preparing multi-grain scale magnesium alloy sheet by non-uniform cross-section rolling method

A non-uniform, magnesium alloy technology, used in metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as poor heat resistance, poor strength and toughness of magnesium alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Taking the rare earth magnesium alloy GW103K as an example, a detailed implementation is given. The following embodiments involve three steps including: non-uniform section plate forming, homogenizing annealing and multi-pass plate rolling, wherein:

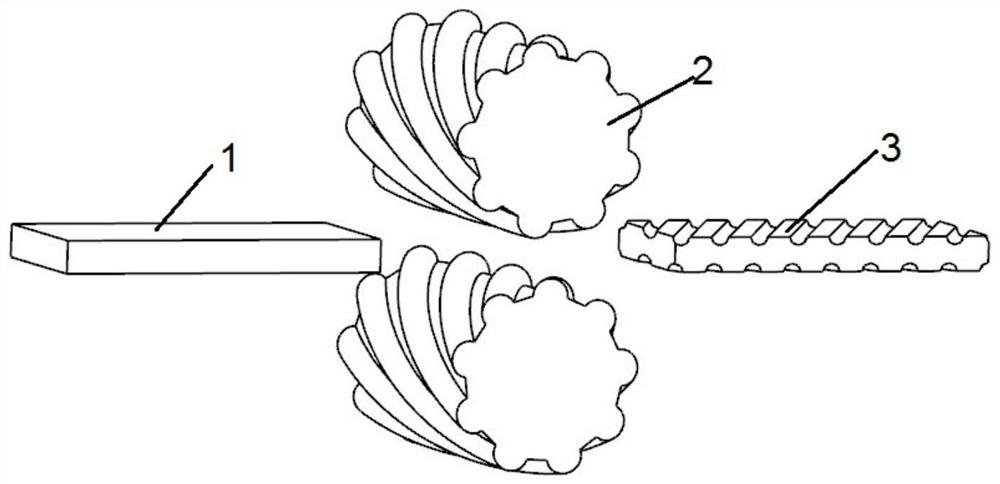

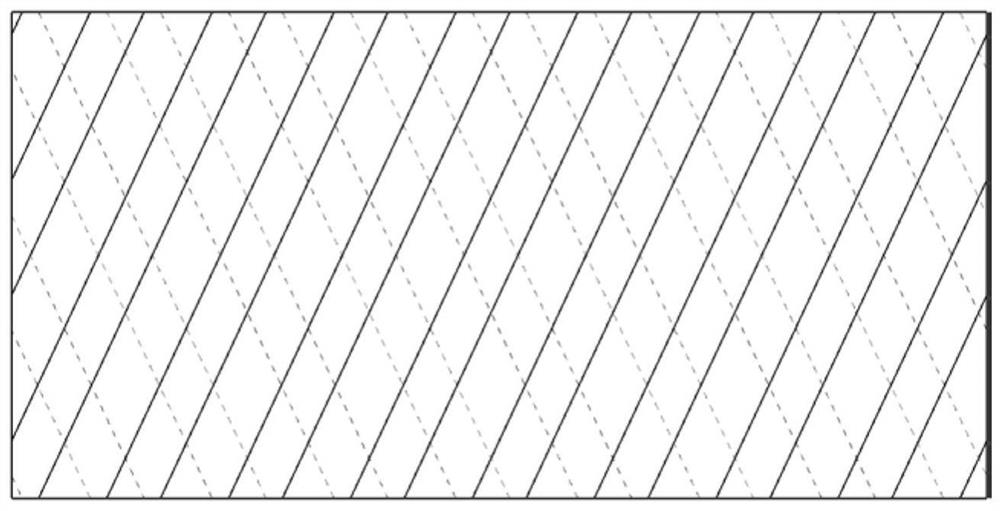

[0035] Step 1: Sheet forming with non-uniform cross-section, such as figure 1 As shown, before rolling, the GW103K magnesium alloy plate 1 is put into a vacuum heat treatment furnace and heated to 330°C, and kept for 10 minutes. After taking it out, the GW103K magnesium alloy plate 1 is rolled with a semicircular pattern roll 2 immediately to form a non-woven fabric. Sheets of uniform cross-section3, such as figure 2 As shown, the upper and lower surfaces form a cross pattern.

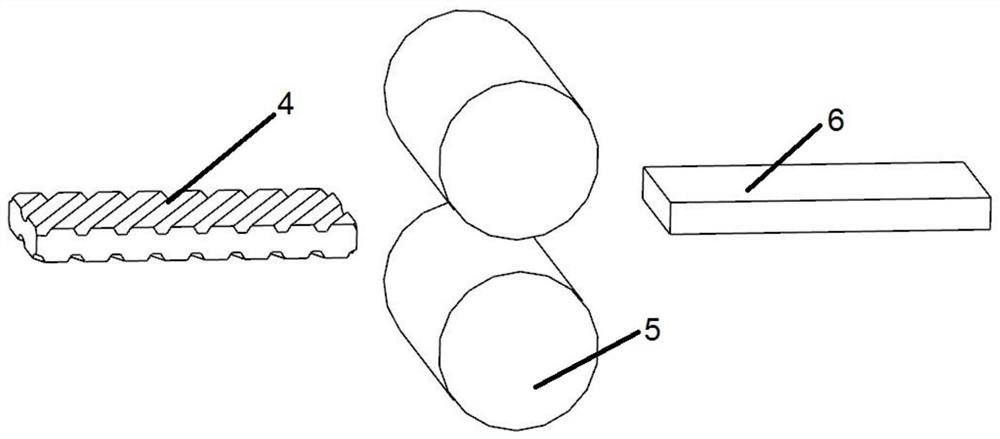

[0036] Step 2: Annealing Annealing, put the GW103K magnesium alloy non-uniform cross-section plate 3 obtained in Step 1 into a vacuum heat treatment furnace, keep it at 325°C for 1 hour, so that the grains become uniform without excessive growth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com