A paint-free door laminating machine

A technology of laminating machine and paint-free door, which is applied in the direction of manufacturing tools, wood processing appliances, etc., can solve the problems of insufficient quality of laminating film, inability to cover the outer edge of the film, and insufficient cooling effect, etc. Achieving the effect of high arrival rate, good cooling effect and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] as attached figure 1 to attach Figure 7 Shown:

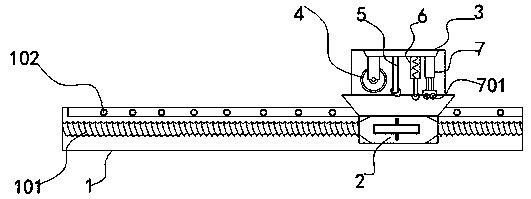

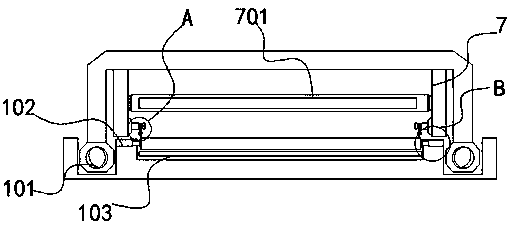

[0031] The invention provides a paint-free door laminating machine. The paint-free door laminating machine includes a fixed bottom plate 1 and a lead screw 101. The left and right sides of the fixed bottom plate 1 are provided with lead screws 101, and the two lead screws 101 are embedded The cover is provided with a lead screw mover 2, the bottom of the fixed bottom plate 1 is rotatably connected with a slide bar 103, and the left and right sides of the front inner side of the fixed bottom plate 1 are fixedly connected with hydraulic rods 102;

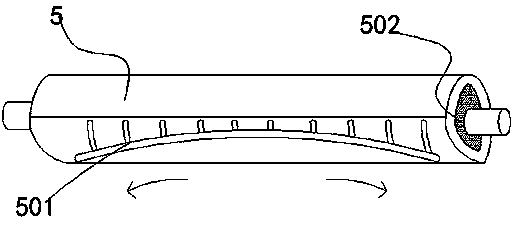

[0032] A truss 3 is fixedly connected to the top of the lead screw mover 2, and the bottom of the truss 3 is fixedly connected with a film material roll 4, a heating roller 5, an auxiliary pressure roller 6, and a circulation pump 7 in order from left to right. The surface of the heating roller 5 is integrated with The heating plate 501 is fixedly connected with the heating wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com