A Rapid Prototyping Method for Magnetorheological Composite

A magnetorheological and composite technology, which is applied in the direction of manufacturing tools, additive manufacturing, and additive processing, can solve the problems of poor performance of heterogeneous magnetorheological composites, improve production efficiency, economy, and good performance , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

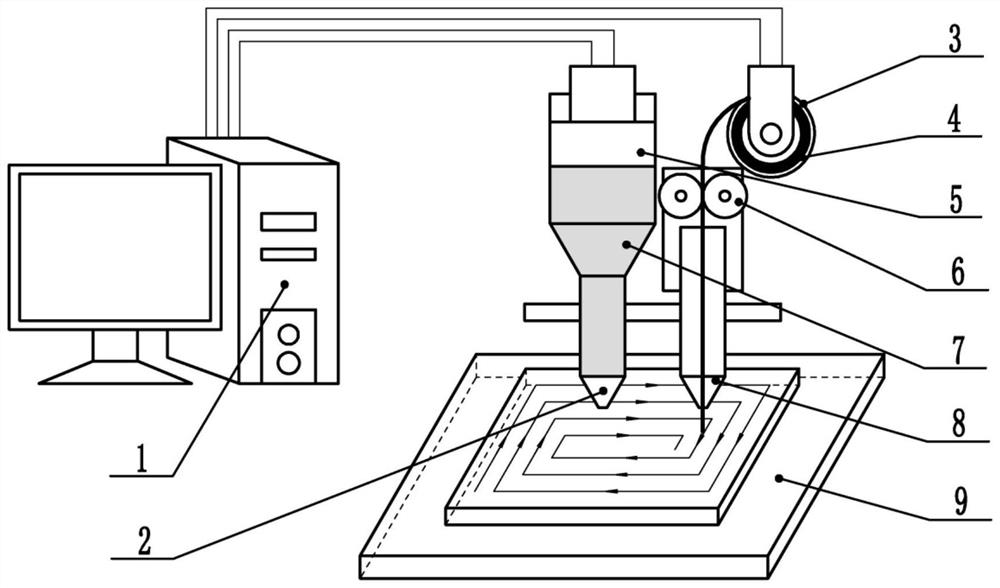

[0041] In this embodiment, the fusion wire deposition method (Fused Deposition Modeling, FDM) and the pressurized injection method are used to realize the manufacture of the magnetorheological composite. The FDM method has the advantages of a wide range of available materials, low cost, high production efficiency, and easy production. It is currently the 3D printing technology with the highest degree of commercialization and the widest range of applications. The pressurized injection method of this embodiment is realized by using a driving mechanism and a pressurizing device. Specifically, the driving mechanism is a servo controller, and the control accuracy of the servo controller is higher. As other implementation modes, a general controller can be used; The pressure device adopts the principle of a piston to achieve the purpose of pressurized injection, and as another embodiment, the principle of a screw can also be used to achieve the purpose of pressurized injection. The ...

Embodiment 2

[0055] The steps of this embodiment and embodiment 1 are basically the same, the difference is:

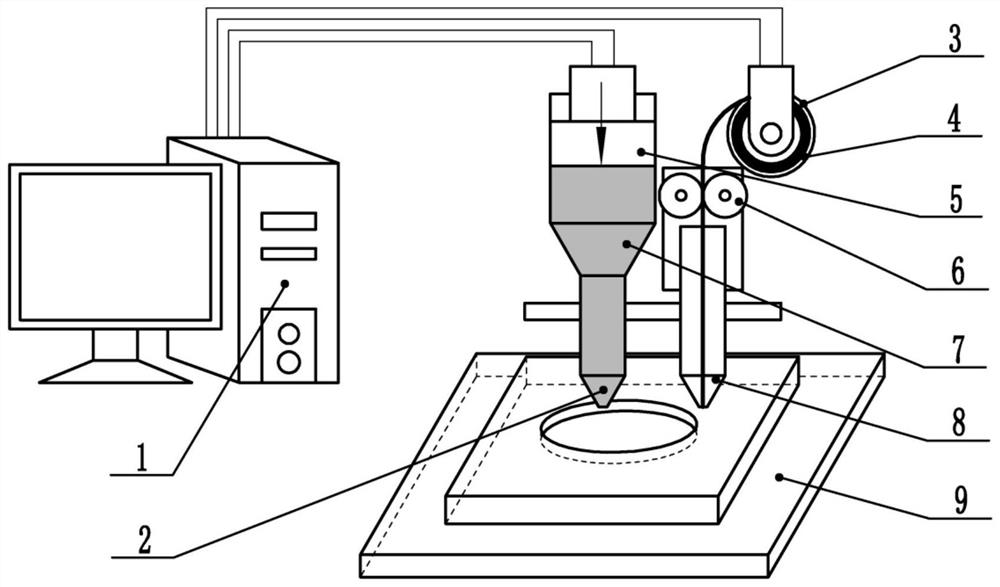

[0056] Such as Figure 12 , the type I magnetorheological elastic material 4 forms a cavity, which is not filled with the magnetorheological viscoplastic material 7, that is to say, the position where the magnetorheological viscoplastic material 7 is filled into the cavity is lower than the cavity The upper surface of the body, and then continue to deposit the type I magnetorheological elastic material 4 on the surface of the filled magnetorheological viscoplastic material 7 to form a "cover" 22, which only encapsulates the cavity.

Embodiment 3

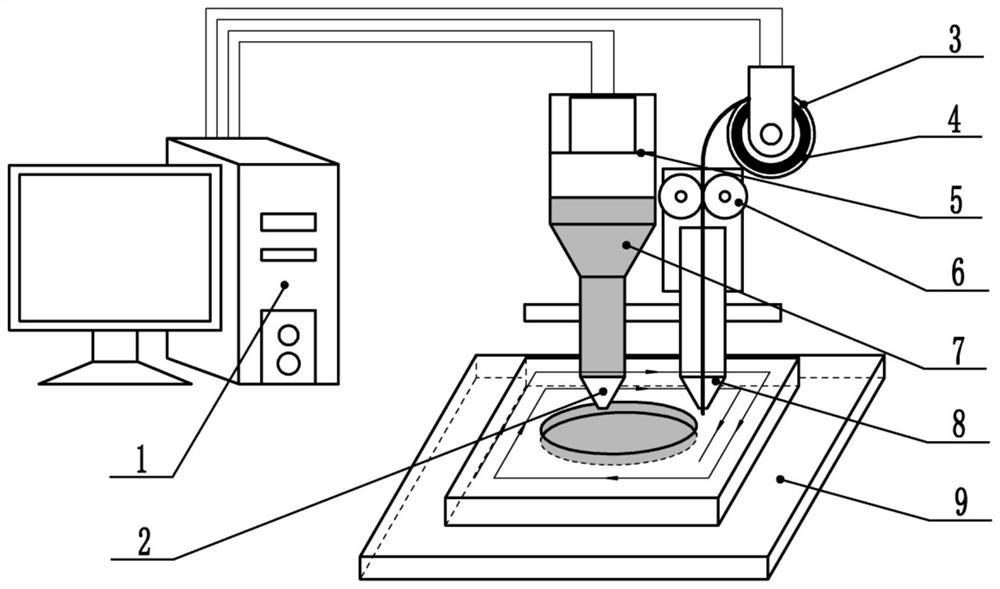

[0058] Such as Figure 13 , the heating nozzle 8 deposits the type I magnetorheological elastic material 4 to form a relatively shallow cavity, and then, the extrusion nozzle 2 fills the cavity with the magnetorheological viscoplastic material 7; on this basis, the soft The depth of the cavity formed by the film matrix, and accordingly, the magnetorheological elastic material in the cavity also gradually increases, that is, the heating nozzle 8 and the extrusion nozzle 2 operate alternately, and the type I magnetorheological elastic material 4 and the magnetorheological viscous The plastic material 7 is printed layer by layer; finally, the heating nozzle 8 is used to print the type I magnetorheological elastic material 4 to form a "cap" 21 to complete the package.

[0059] In this implementation example, the minimum height of each deposition is the lowest printing height of the FDM method, that is, 0.2 mm, and the maximum height of each deposition is less than or equal to 0.6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com