Color printing package blade line removing method

A cleaning method and cutting line technology, which are applied in the printing device, post-processing of printing, printing and other directions, can solve the problems of not being able to determine the completeness of the cutting line, time-consuming and labor-intensive, poor quality packaging film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

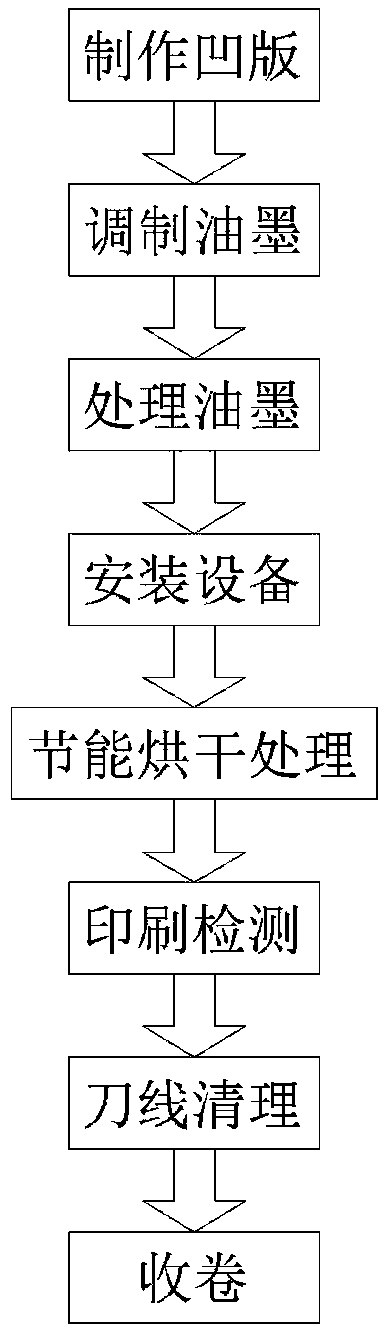

[0023] Such as figure 1 and figure 2 As shown, a color printing packaging knife line cleaning method includes the following steps:

[0024] Step 1, making gravure: according to the pattern standard plate to be printed, place the pattern of the same color on the same gravure, and the depth of the gravure groove is preferably 10 μm;

[0025] Step 2, prepare ink: according to the standard version of the pattern to be printed, prepare the ink of the corresponding color for the color sample in the pattern;

[0026] Step 3, processing ink: according to the printing pattern standard, use a filter to filter the impurities in the ink to avoid the formation of large ink particles due to ink agglomeration;

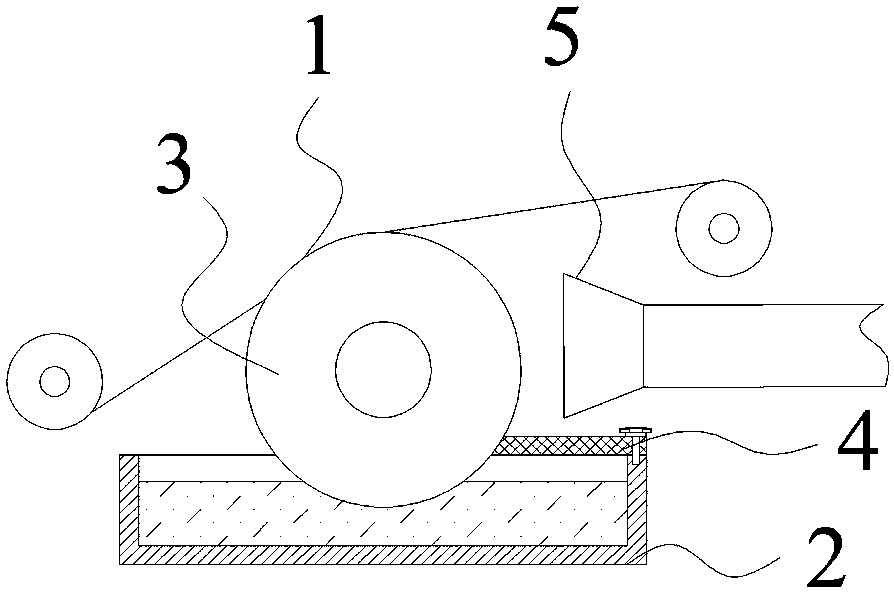

[0027] Step 4, install the equipment: install the intaglio plate produced in step 1 on the printing device, and at the same time place the packaging film to be printed on the starting position, set the ink scraping mechanism 1 in the printing device, and the ink scraping mechanism...

Embodiment 2

[0033] Such as figure 1 and figure 2 As shown, a color printing packaging knife line cleaning method includes the following steps:

[0034] Step 1, making gravure: according to the pattern standard plate that needs to be printed, place the pattern of the same color on the same gravure, and the depth of the gravure groove is preferably 45 μm;

[0035] Step 2, prepare ink: according to the standard version of the pattern to be printed, prepare the ink of the corresponding color for the color sample in the pattern;

[0036] Step 3, processing ink: according to the printing pattern standard, use a filter to filter the impurities in the ink to avoid the formation of large ink particles due to ink agglomeration;

[0037] Step 4, install the equipment: install the intaglio plate produced in step 1 on the printing device, and at the same time place the packaging film to be printed on the starting position, set the ink scraping mechanism 1 in the printing device, and the ink scrapin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com