Automatic steel pipe stacking device

A driving device and automatic technology, which is applied in the direction of transportation, packaging, and object stacking, can solve the problems of high labor intensity, low efficiency, and inability to proceed in an orderly manner, and achieve the effect of neat stacking and improving automation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

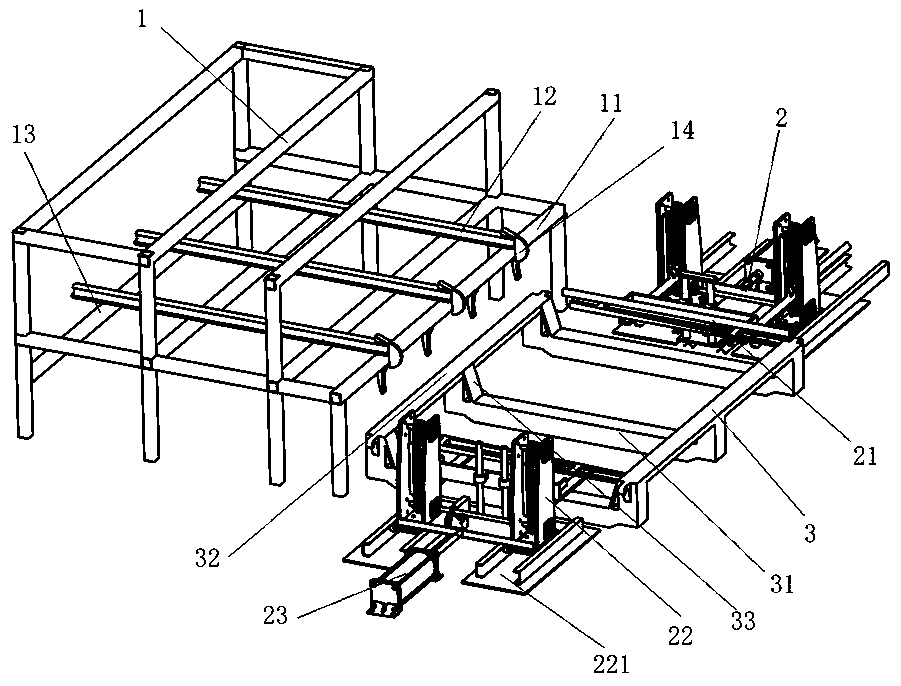

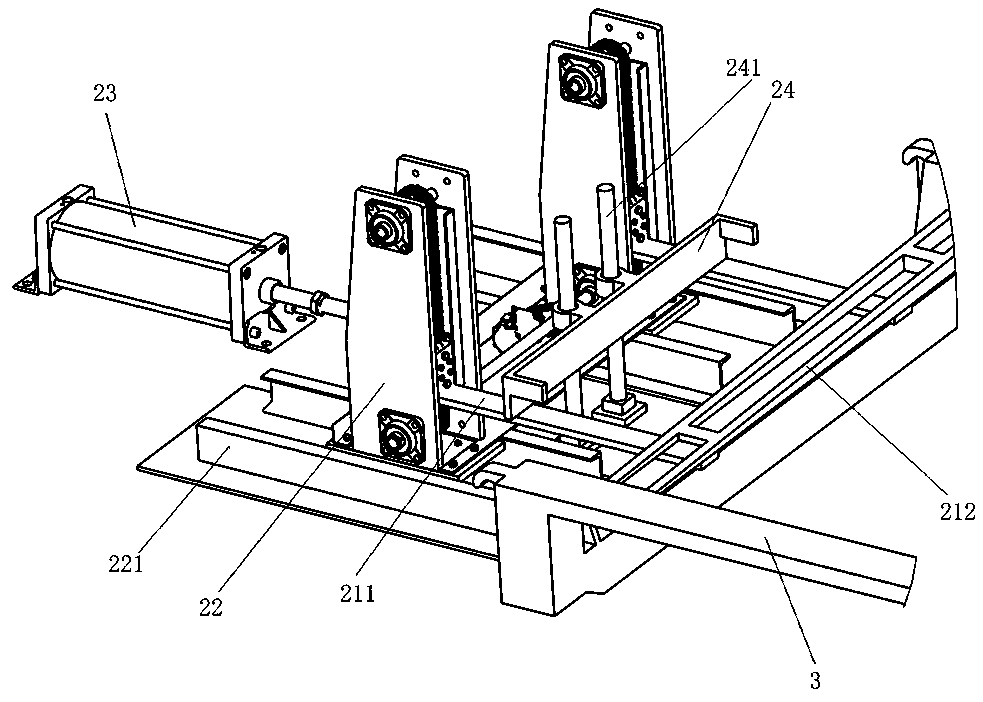

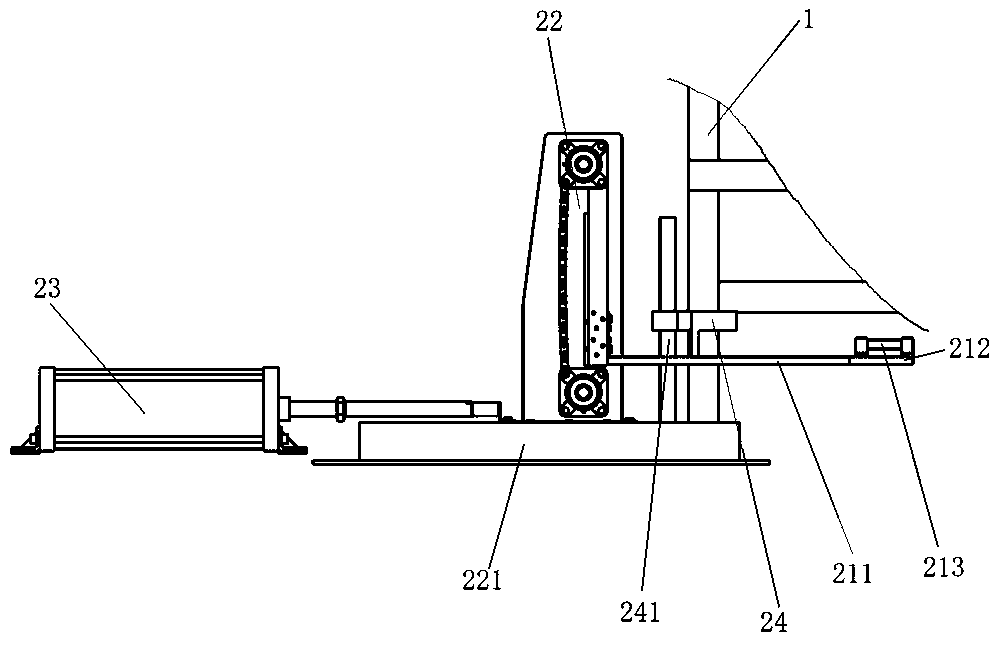

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

[0024] An automatic stacking device for steel pipes, comprising a frame-type feeding rack 1 , a stacking mechanism 2 located on one side of the loading rack 1 , and a material frame 3 located below the stacking mechanism 2 . The loading rack 1 includes a discharge side 11 close to the stacking mechanism 2 and a feed side 13 connected to the discharge side 11 by several linear rails 12. The inclination of the side 11, in production, the segmented steel pipes sent out from the logistics package, container or steel pipe cutting device, etc. are fed from the feed side 13, and the segmented steel pipes can automatically roll down and gather and stack under the action of gravity. 11 places on the discharge side. The discharge side 11 is hinged at the end of the three straight rails 12 and is equipped with a discharge device 14 arranged at intervals. The discharge device 14 is a fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com