Production line for producing fluorescent materials through two-step method

A fluorescent material and production line technology, applied in the field of fluorescent material processing equipment, can solve the problems of residue, waste of raw materials, easy sticking, etc., and achieve the effects of low processing cost, high processing efficiency, and avoidance of raw material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

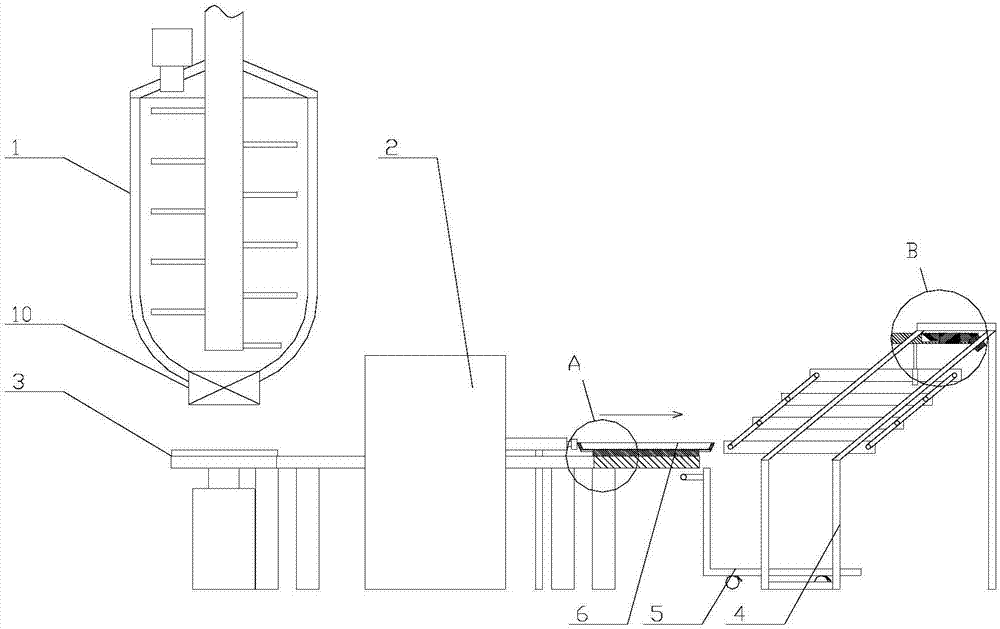

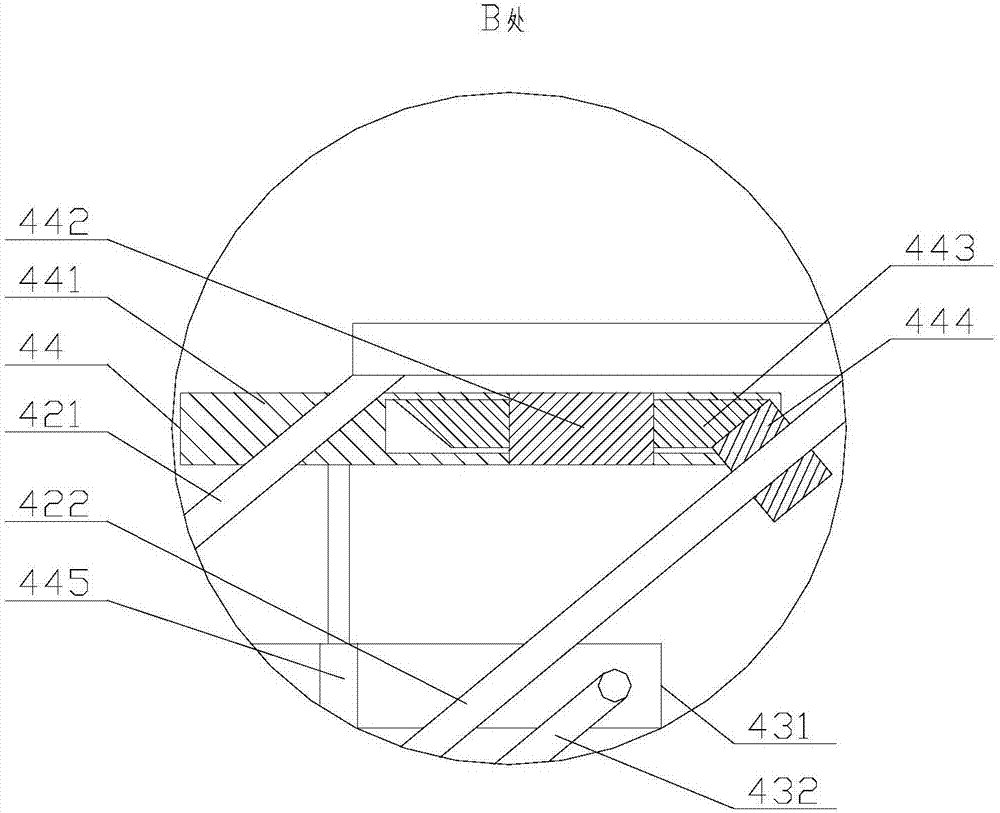

[0028] The present invention as Figure 1-9 As shown, it comprises a reactor 1, a drying box 2, a transfer device 3, a distributing device 4, a trolley 5 and several trays 6, and the reactor 1 is arranged on one side of the drying box 2; the top of the reactor is provided with There is a feeding valve, and the bottom of the reaction kettle 1 is provided with a feeding valve 10, and the side of the drying box facing the reaction kettle is provided with a feeding port, and the side facing away from the reaction kettle is provided with a discharge port;

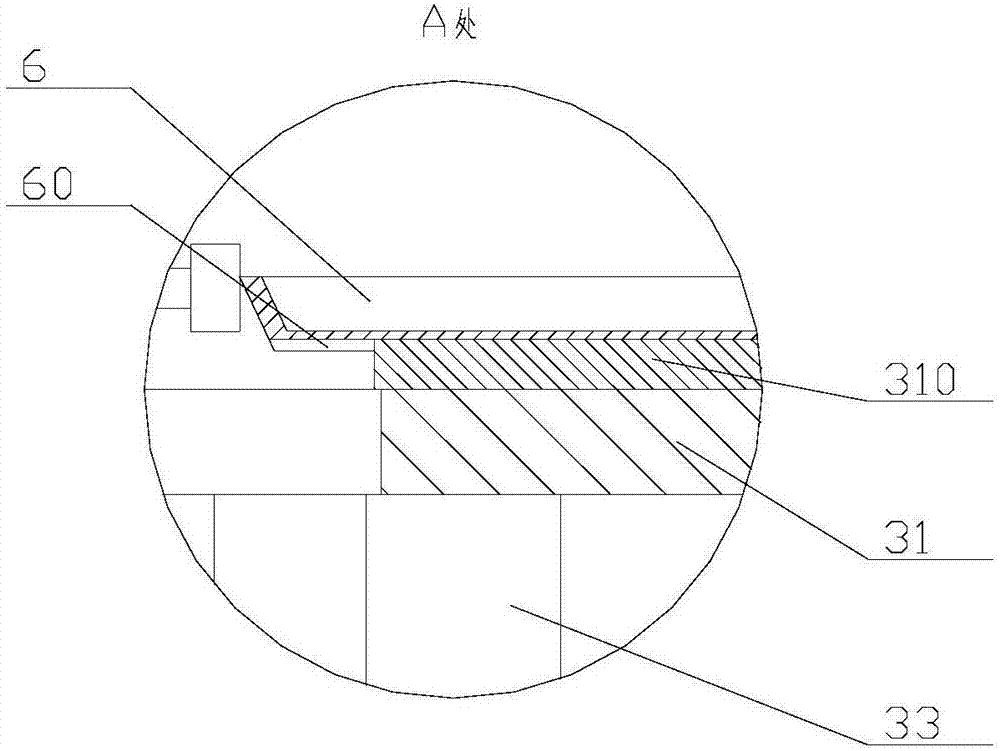

[0029] The transfer device 3 includes a transfer plate 31, a transfer drive device 32 and several support columns 33, the transfer plate 31 is in the shape of a ring, and is slidably connected to the tops of several support columns 33 fixedly connected on the ground, the transfer The driving device 32 is connected to the bottom surface of the transfer plate 31 and is used to drive the transfer plate 31 to rotate around its own a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com