A mechanism for improving the verticality qualification rate of steel lattice columns in open-cut tunnel foundation pit and using method thereof

A technology for steel lattice columns and open-cut tunnels, which is used in excavation, infrastructure engineering, underwater structures, etc., can solve the problems of inaccurate installation and positioning, difficult deviation correction, and high cost of deviation correction, and achieves vertical installation and avoids later stages. effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

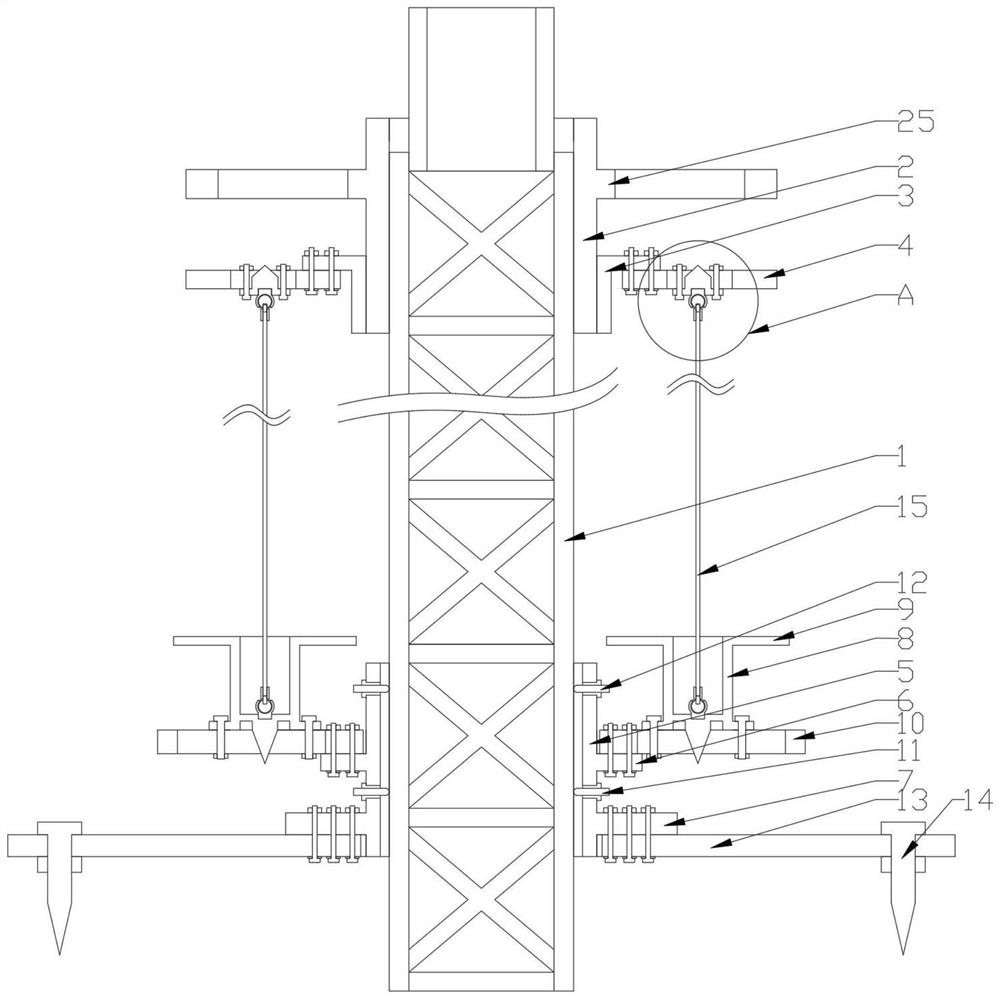

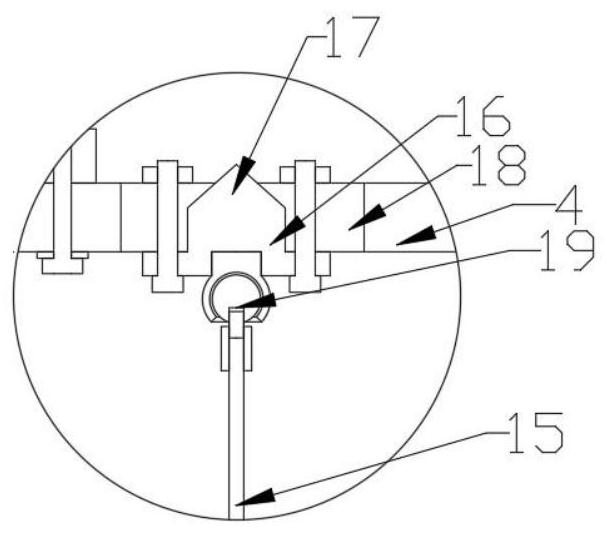

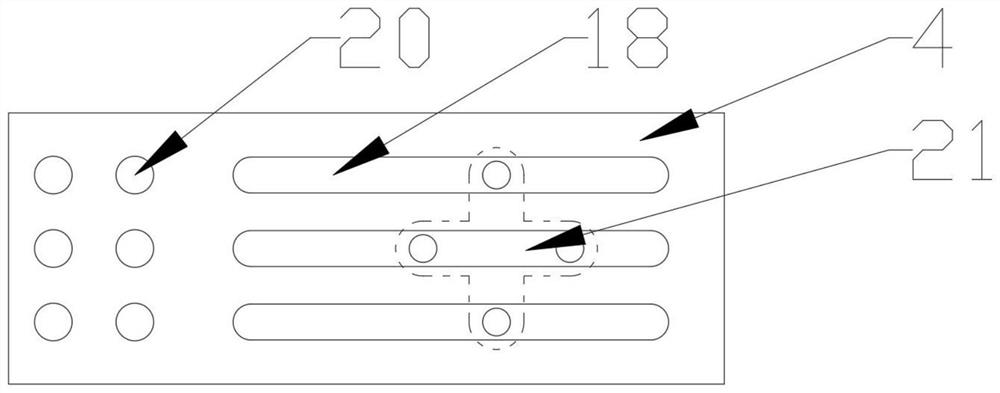

[0027] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0028] Such as figure 1 As shown, the present invention is a mechanism for improving the verticality qualification rate of the steel lattice column of the foundation pit of an open-cut tunnel; it includes a support sleeve A and a support sleeve B sleeved on the steel lattice column, wherein the support sleeve A is located on the At the opposite top of the structural column, the support sleeve B is located at the relative bottom of the steel lattice column; wherein the support sleeve A is sequentially provided with a steel lattice column beam connection seat and a reference plate connection seat A, wherein the steel lattice column beam connection seat includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com