A vertical simulation experiment method of metal screw pump

A simulation experiment and screw pump technology, applied in pump testing, liquid displacement machinery, machine/engine, etc., can solve the problems of increasing stator wear and not being able to simulate the working state of screw pumps well, and achieve enhanced sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

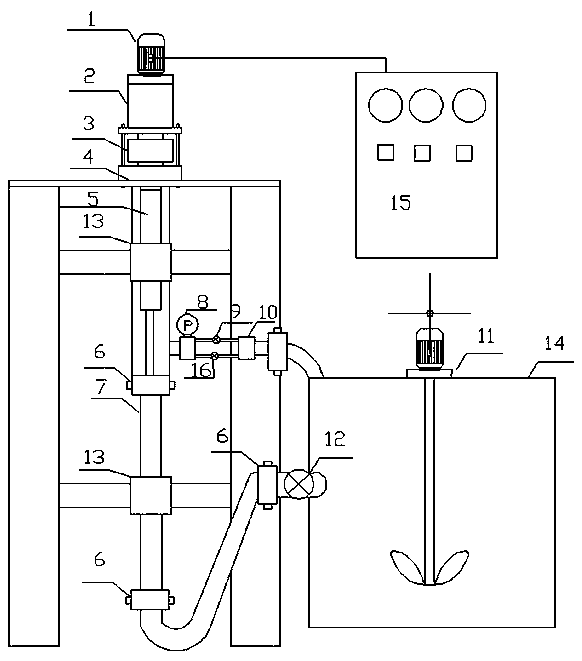

[0017] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0018] like figure 1 As shown, a metal screw pump vertical simulation experiment method includes a drive system, a pump system, and a stirring system connected in sequence. The drive system and the pump system are both vertically arranged, and the pump system is vertically arranged on a support , while the drive system is vertically connected to the power input end of the pump system; the pump system and the mixing system are connected in a circular manner through the pump-in pipeline and the pump-out pipeline, and the pump-in pipeline between the pump system and the mixing system A metering system is connected to it. The driving system drives the pump system to work. The pump system sucks the sand-containing liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com