High-speed mainshaft bearing constant-pressure pre-loading device

A technology of constant pressure preload and high-speed spindle, which is applied in the direction of positioning device, drive device, support, etc. It can solve the problems of poor preloading method of high-speed spindle bearings, achieve the effects of improving rigidity, stable operation, and preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

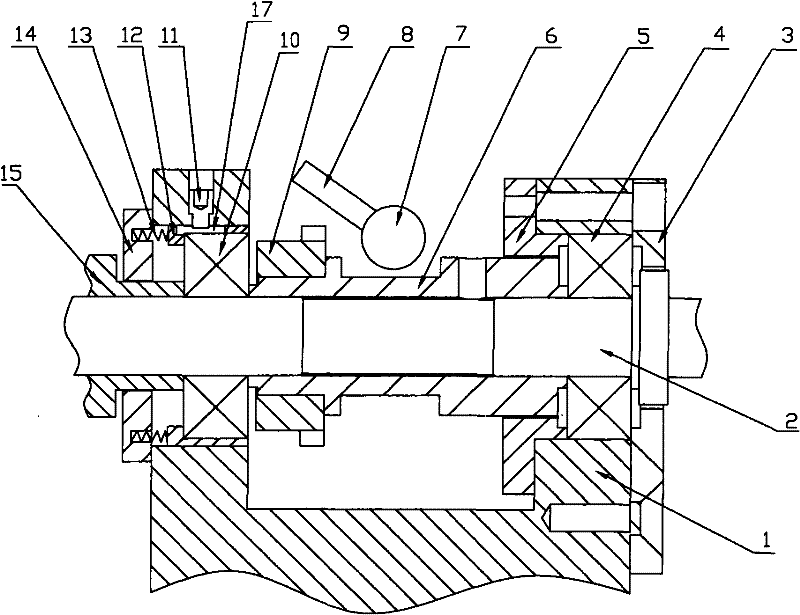

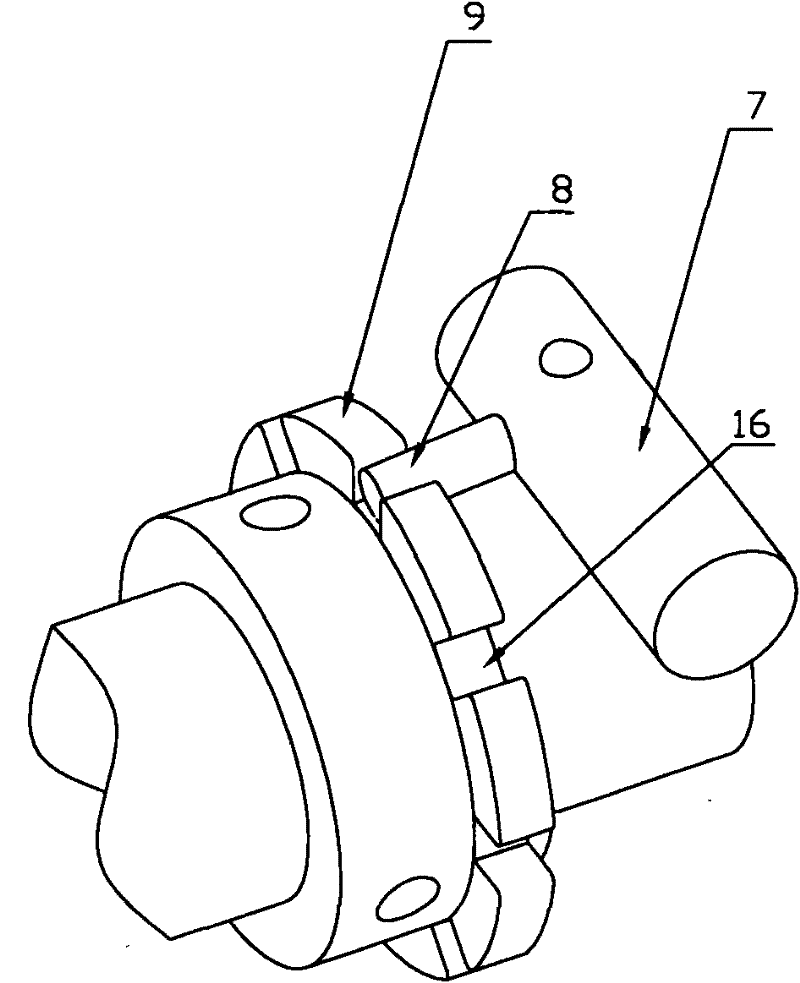

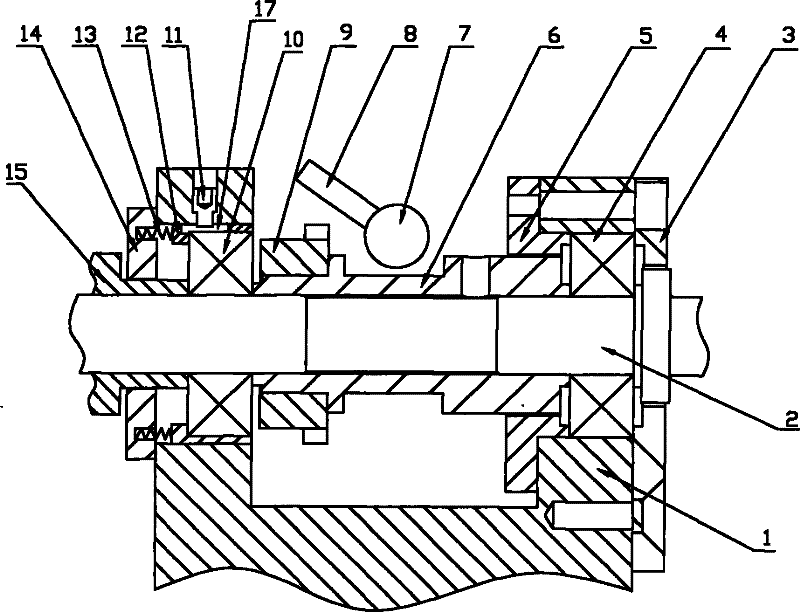

[0027] The present invention will be described in detail below with reference to the accompanying drawings.

[0028] refer to figure 1 and figure 2 , a high-speed spindle bearing constant pressure preloading device of the present invention comprises a spindle box 1, a first bearing 4 and a second bearing 10 arranged at the front and rear ends of the spindle box 1, and a first bearing 4 and a second bearing 10 arranged at the front and rear ends of the spindle box 1. The main shaft 2 in the second bearing 10, the first bearing 4 is fixed in the main shaft box 1 by a bearing front end cover 3 and a bearing rear end cover 5, and an inner sleeve is installed between the first bearing 4 and the second bearing 10 6. The second bearing 10 is installed in a sliding sleeve 12 with interference. The sliding sleeve 12 is in clearance fit with the spindle box 1. A spring 13 is provided on one side of the sliding sleeve 12, and a rear end cover 14 is provided on the rear side of the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com