An electronic expansion valve

An electronic expansion valve and valve seat technology, which is applied in the field of solenoid valves, can solve the problems of eliminating or reducing noise, electronic expansion valve noise, and the inability to improve the electronic expansion valve, etc., to achieve the effect of reducing noise and weakening the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

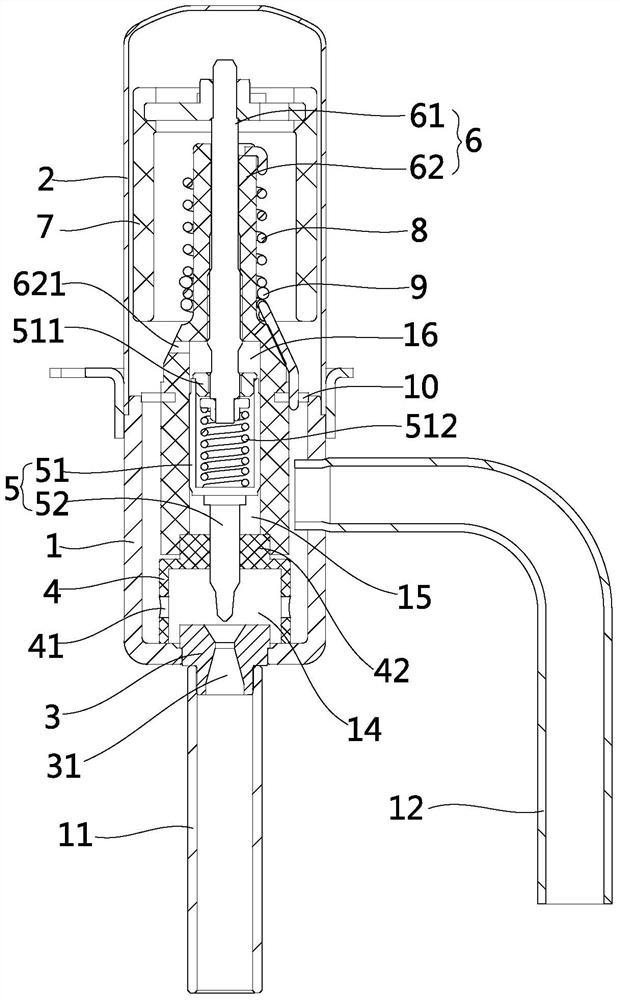

[0030] Such as figure 1 As shown, the electronic expansion valve in this embodiment includes a valve seat 1, a sleeve 2, a valve port seat 3, a guide sleeve 4, a valve needle 5 and a nut assembly 6. The valve seat 1 is provided with an inlet and an outlet, and the inlet is connected with In the intake pipe 12, the valve port seat 3 is provided with a valve port 31, and the valve port seat 3 is installed on the outlet, and an outlet pipe 11 is also connected at the outlet, and the intake pipe 11 communicates with the valve port 31. The nut assembly 6 includes a screw 61 and a nut 62. The nut 62 is a resin piece. The screw 61 is screwed into the nut 62. The outer side wall of the nut 62 is provided with a connecting piece 10, and the connecting piece 10 is welded and fixed to the inner wall of the valve seat 1. The valve needle 5 includes a large-diameter section 51 and a small-diameter section 52. The large-diameter section 51 is located in the inner cavity of the nut 62 and is s...

Embodiment 2

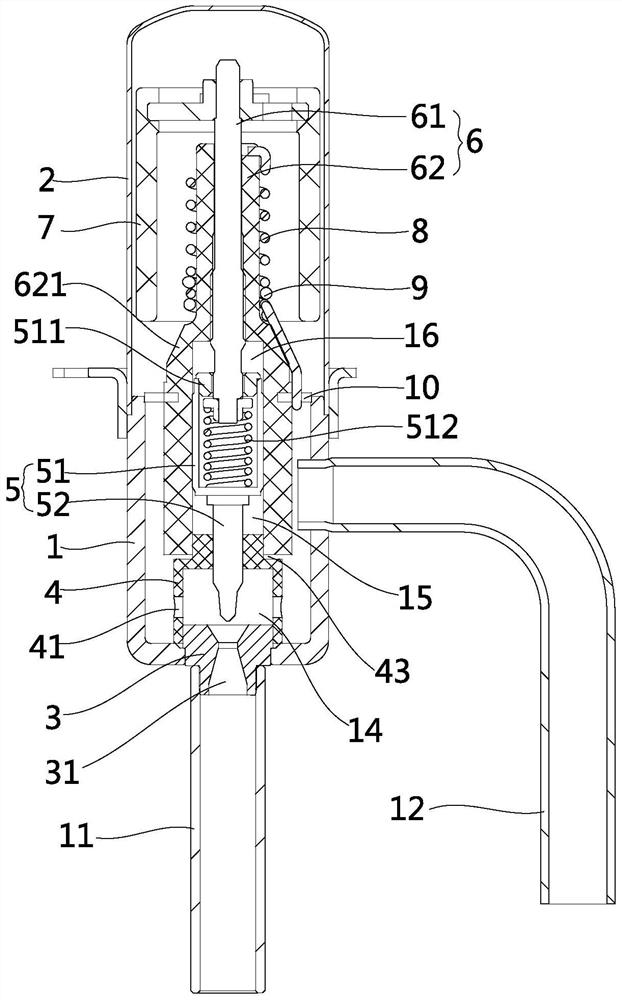

[0038] Such as figure 2 As shown, the difference from the first embodiment is that the upper end of the guide sleeve 4 in this embodiment is provided with a positioning step 43. When installed at room temperature, there is a certain gap between the horizontal plane of the positioning step 43 and the lower end surface of the nut 62 , The vertical surface of the positioning step 43 abuts against the inner ring surface of the nut 62, so that the nut 62 plays an internal guiding role for the guide sleeve 4. The inner side of the lower end of the guide sleeve 4 abuts the outer side of the valve port seat 3, so that the valve port seat 3 The guide sleeve 4 plays an external guiding role. Under the action of high temperature or fluid medium, the horizontal surface of the positioning step 43 abuts against the lower end surface of the nut 62, which further plays a role of limiting. Therefore, the installation method of the guide sleeve 4 in this embodiment can further improve the coaxia...

Embodiment 3

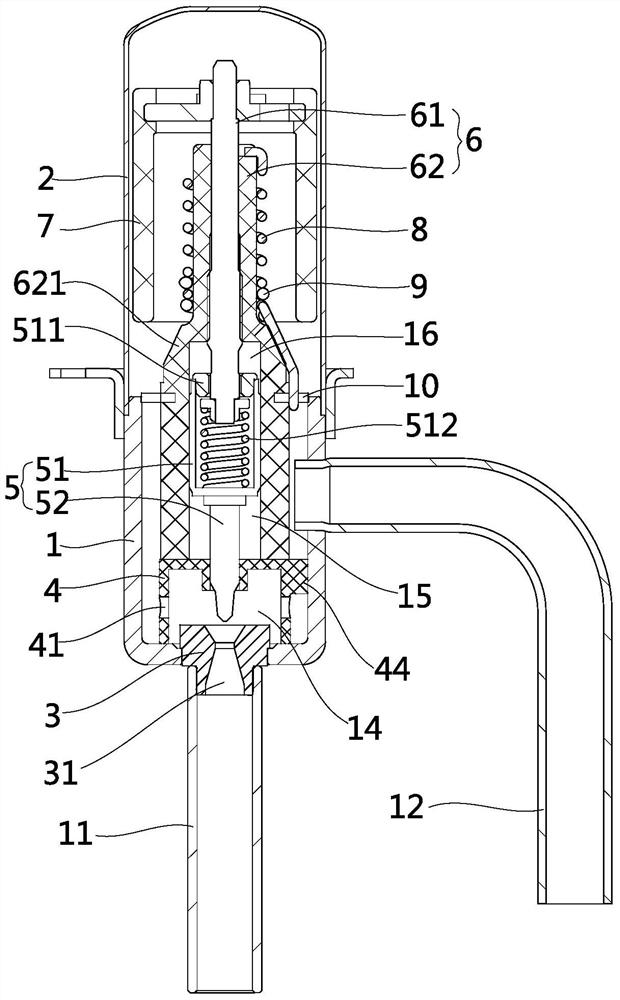

[0040] Such as image 3 As shown, the difference from the second embodiment is that the upper end surface of the guide sleeve 4 in this embodiment abuts against the lower end surface of the nut 62, and the side wall of the guide sleeve 4 is provided with a plurality of positioning blocks 44 at intervals in the circumferential direction. The outer side of the valve seat abuts the inner side wall of the valve seat 1, and the valve seat 1 realizes the outer guidance of the guide sleeve 4, which ensures the coaxiality of the valve needle 5, the nut 62 and the guide sleeve 4, and reduces the guide sleeve 4 in the high temperature environment. The deformation of the valve pin 5 and the nut 62 affect the clearance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com