Automatic tubing and sucker rod clamping shackle device for oil field workover treatment

A technology for pipe rods and workovers, applied in drill pipe, drill pipe, casing and other directions, can solve the problems of high labor intensity, difficult operation and construction conditions, low safety operation coefficient, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. . In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

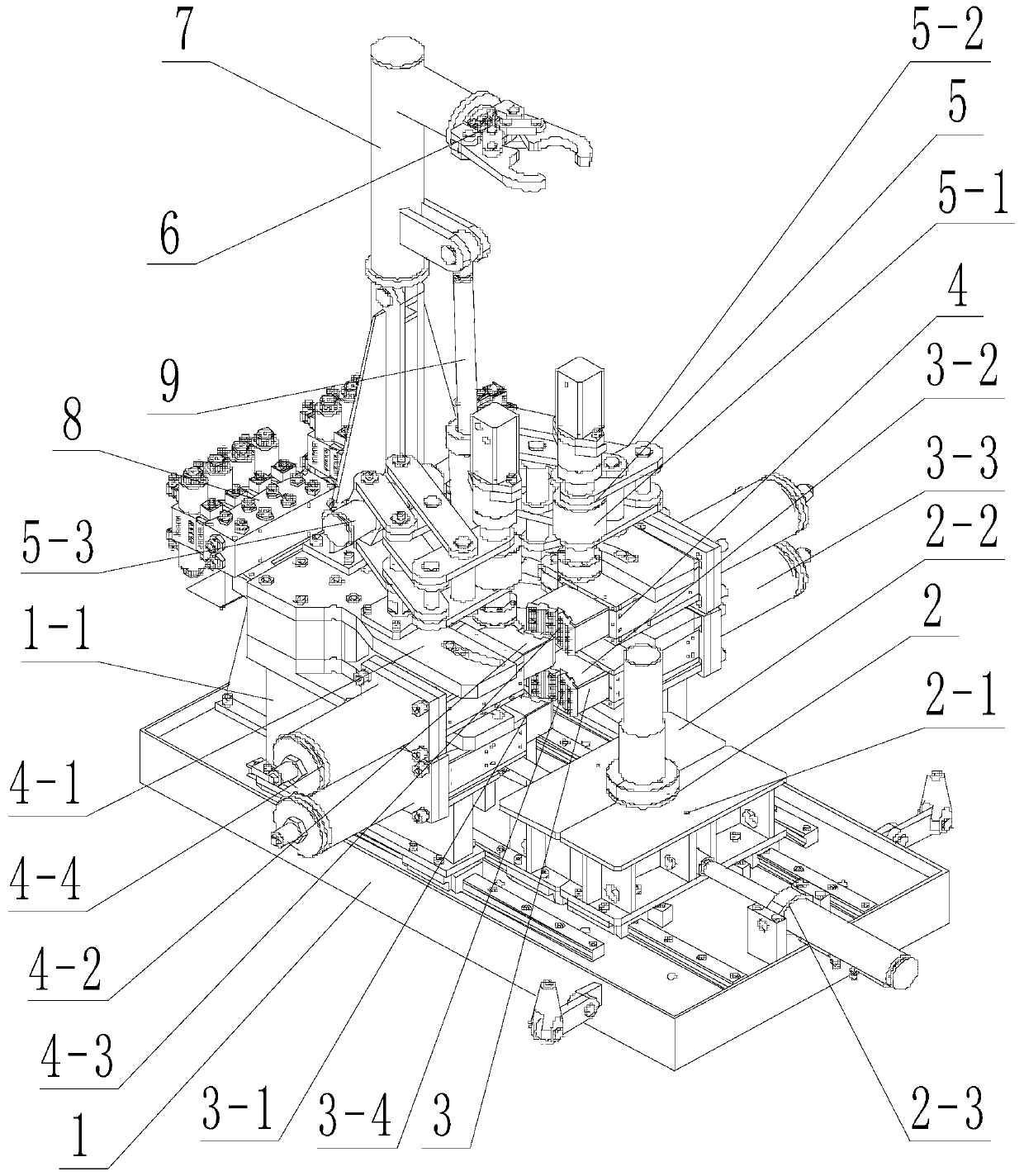

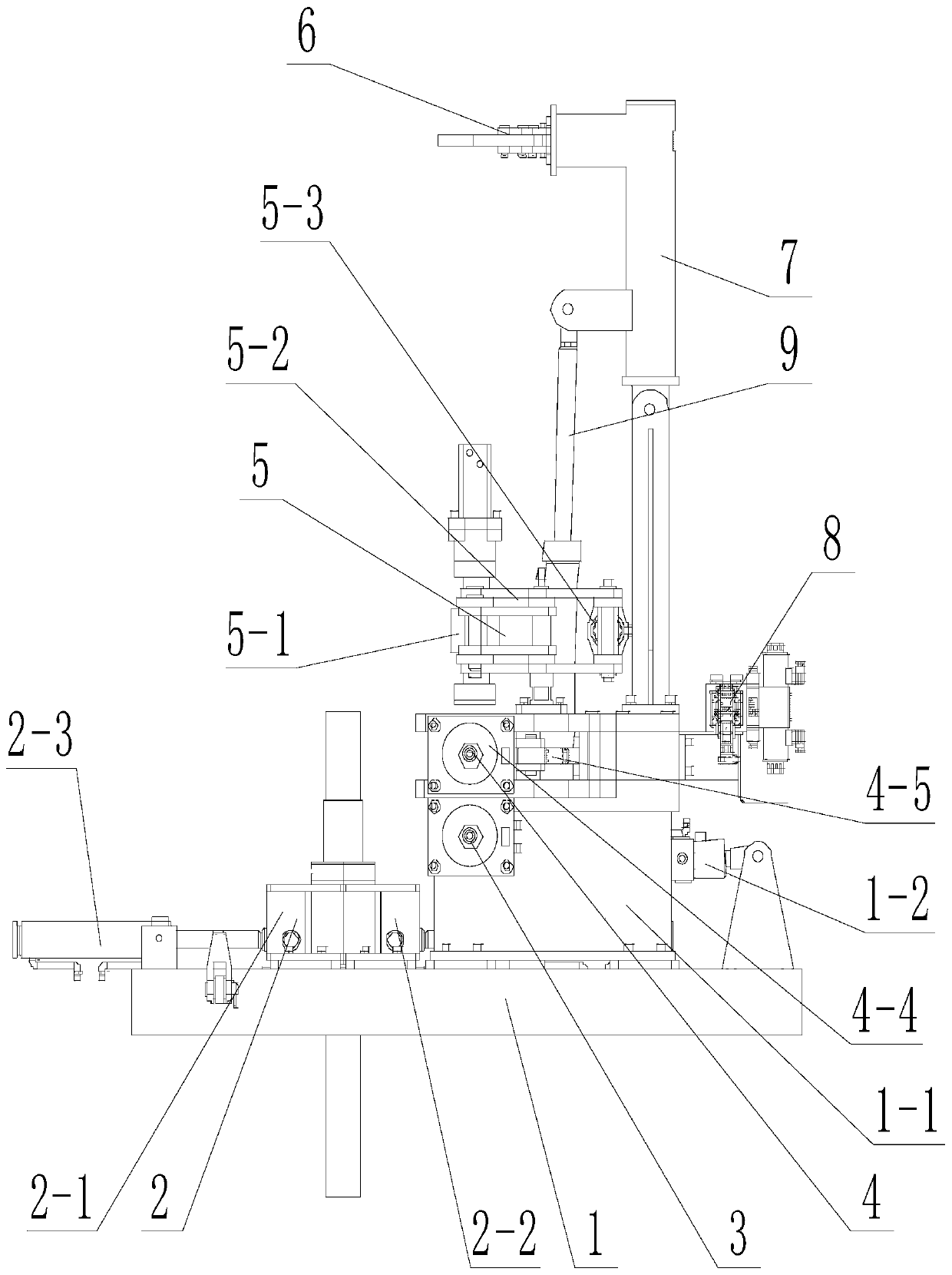

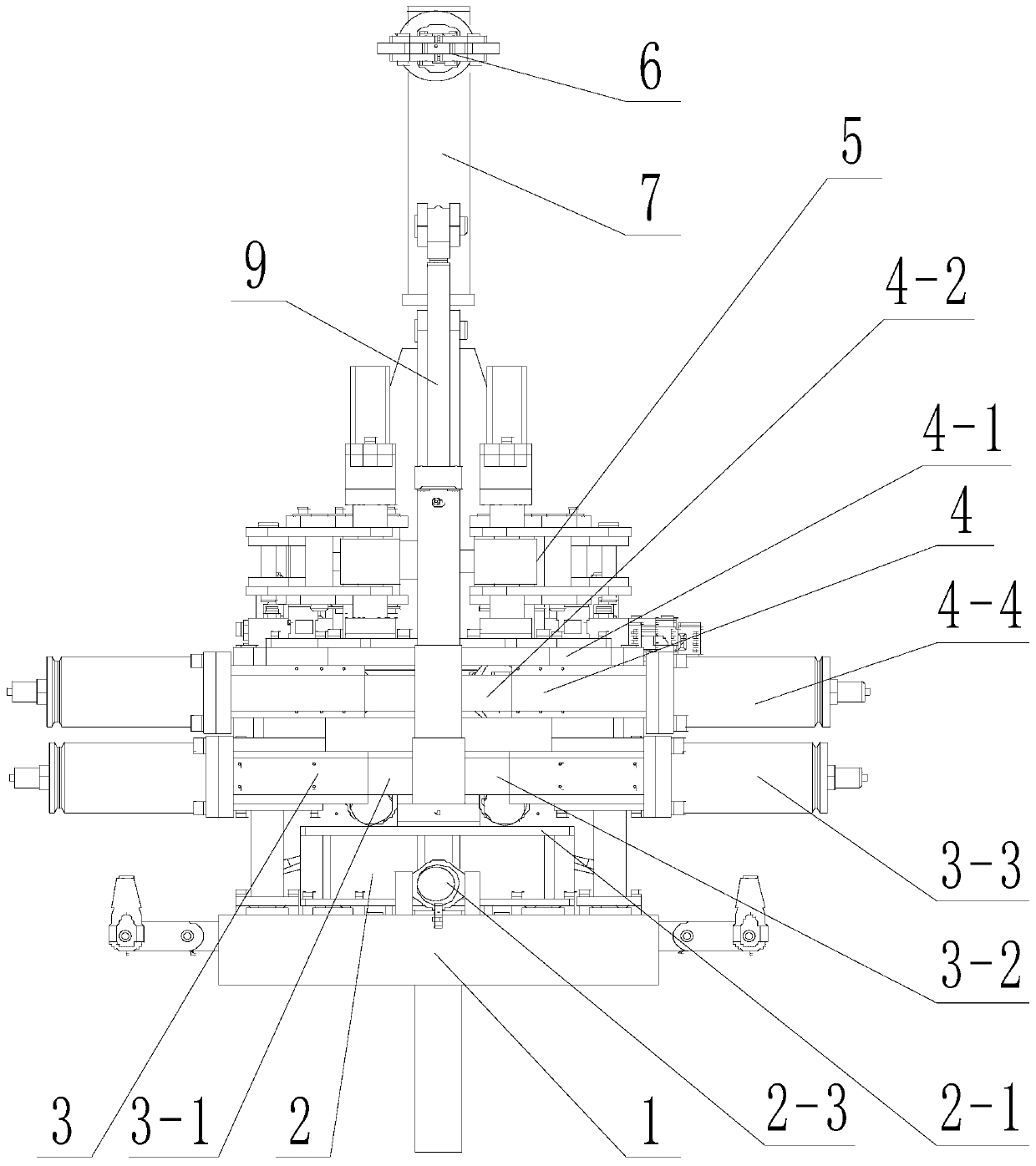

[0077] Such as Figure 1 to Figure 4 As shown, an embodiment of the present invention proposes a pipe rod automatic tightening and breaking device for oil field workover operations, comprising: a support 1, a positioning mechanism 2, a clamping mechanism 3, a flushing mechanism 4, a tightening and unfastening mechanism Buckle mechanism 5 and control system 8; s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com