Low-frequency response parallel spring safety valve

A low-frequency response, parallel technology, applied in the direction of fluid pressure actuation system safety, fluid pressure actuation devices, servo motor components, etc., can solve problems such as the difficulty of system pressure maintenance, reduce leakage, realize pressure maintenance, and realize effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

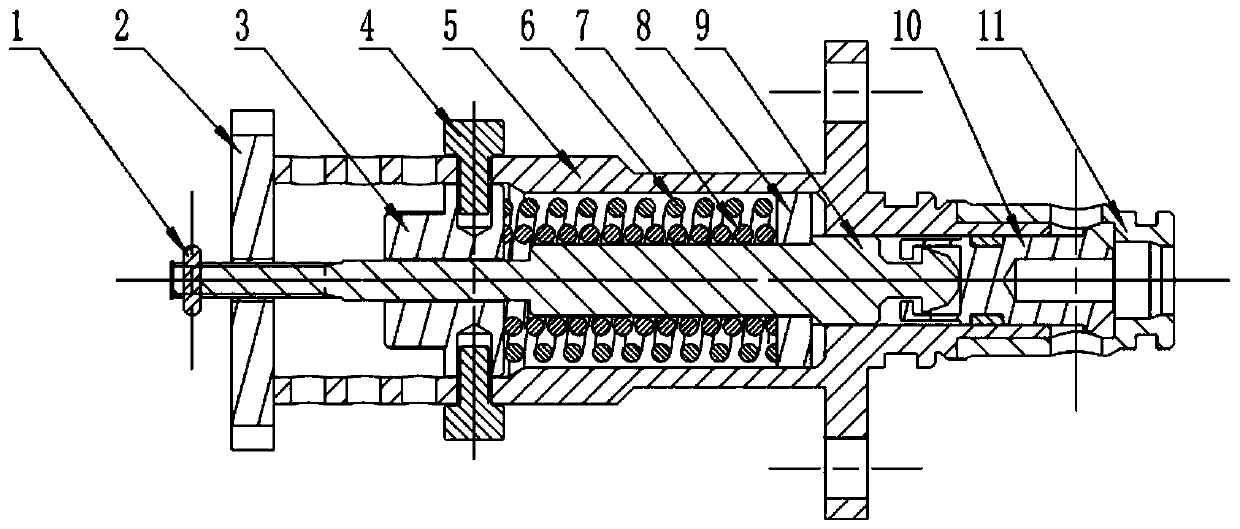

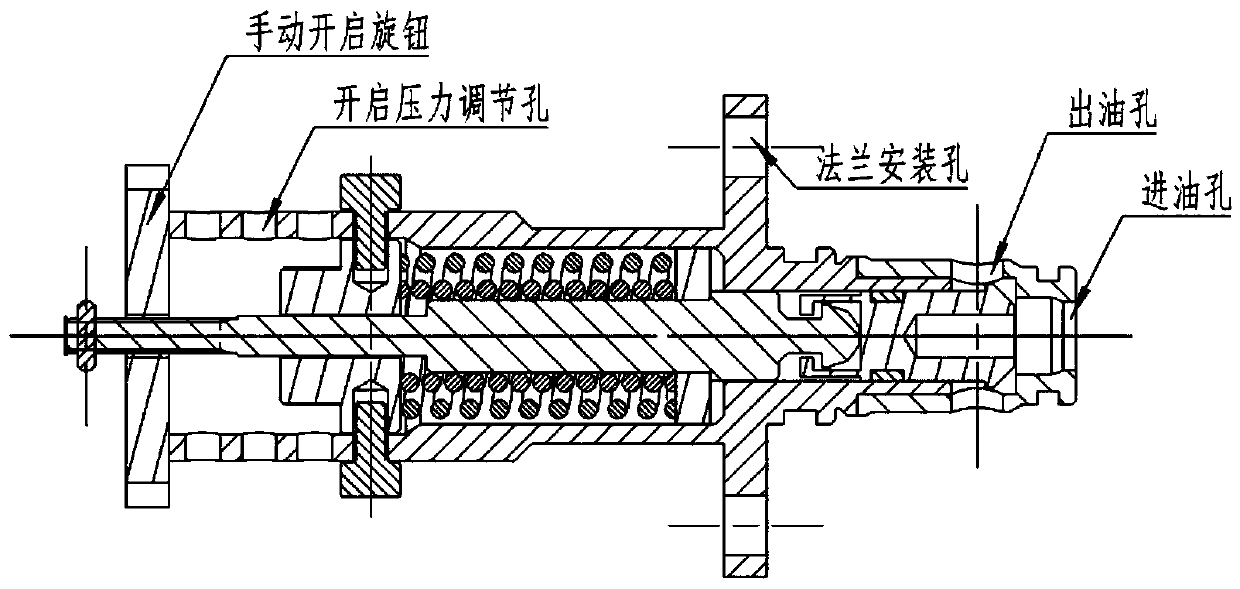

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] see figure 1 , a low-frequency response parallel spring safety valve, including threaded knob 2, pressure limit block 3, adjusting screw 4, housing 5, spring, backing plate 8, guide spool 9, sealing spool 10, sealing spool seat 11;

[0014] The housing 5 is a hollow cavity with two sections of shaft holes. The pilot valve core 9 is a stepped shaft with four steps. The first step of the core 9 is matched with the smaller shaft hole of the housing 5, the rest of the guide valve core 9 is placed in the larger shaft hole of the housing 5, and the third step of the guide valve core 9 is provided with a pressure limit block 3 , the corresponding housing is provided with a pressure adjustment hole, the adjustment screw 4 is installed in the pressure adjustment hole, the pressure can be adjusted to the pressure limit block 3, the guide valve core 9 is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com