Shock mitigation system capable of adjusting amplitude

A vibration reduction system and adjustable technology, applied in the field of vibration reduction, can solve the problems of low application rate of the vibration reduction system and adjustment of vibration amplitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

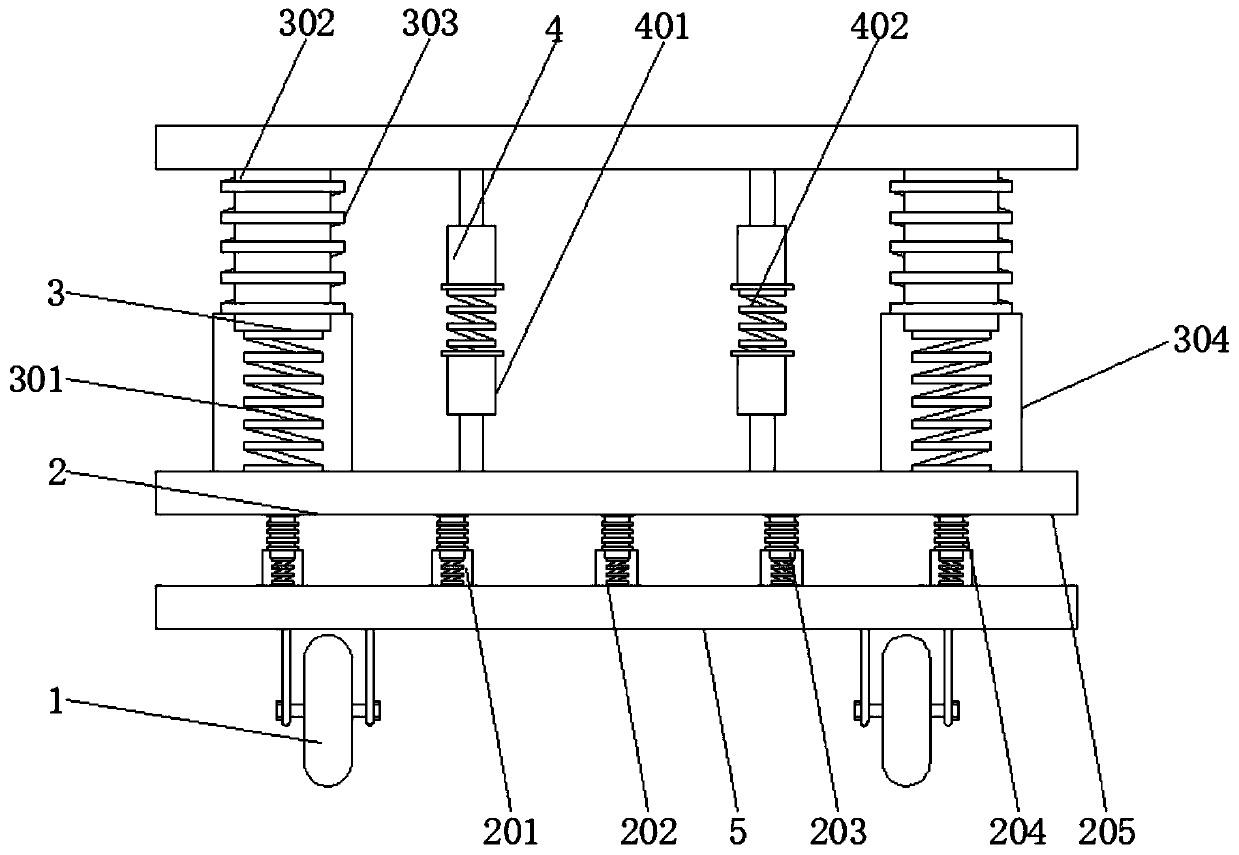

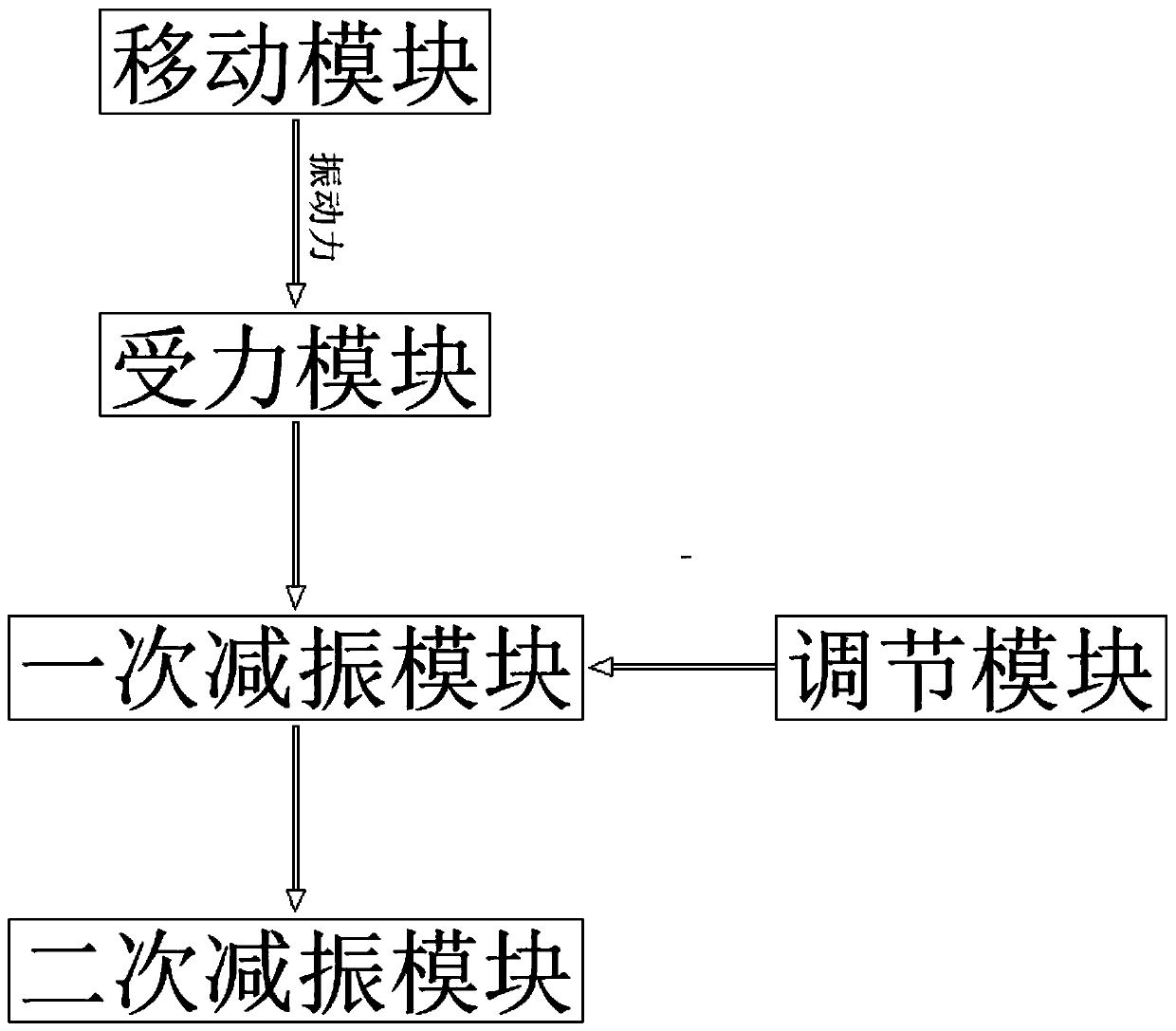

[0019] As a preferred embodiment of the present invention: the primary damping module 2 includes a No. 1 sleeve 201, and a No. 1 inner spring 202 is arranged inside the No. 1 sleeve 201, and the inside of the No. 1 sleeve 201 is close to the top of the No. 1 inner spring 202 Connected with a No. 1 telescopic column 203, the outer surface of the No. 1 telescopic column 203 is provided with a No. 1 outer spring 204, and the top of the No. 1 outer spring 204 is connected with a buffer plate 205. After the No. 1 sleeve 201 receives the vibration force, the vibration force is transmitted to No. 1 The inner spring 202 and the No. 1 inner spring 202 are extended or shortened. When the No. 1 inner spring 202 is extended or shortened, the No. 1 telescopic column 203 moves up or down on the inner wall of the No. 1 sleeve 201, and the No. 1 inner spring 202 Squeeze, at this time the No. 1 outer spring 204 is extended or shortened under the force of the No. 1 sleeve 201, and the No. 1 oute...

Embodiment 2

[0021] As a preferred embodiment of the present invention: the secondary damping module 3 includes a No. 2 sleeve 304, and a No. 2 inner spring 301 is installed inside the No. 2 sleeve 304, and the inside of the No. 2 sleeve 304 is close to the No. 2 inner spring 301 No. 2 telescopic column 302 is connected to the top of the No. 2 telescopic column 302, and No. 2 outer spring 303 is arranged on the outer surface of No. 2 telescopic column 302. The buffer plate 205 transmits the shock force after the primary vibration reduction to No. 2 sleeve 304, and No. 2 sleeve 304 receives Move up after force, now No. 2 inner spring 301 and No. 2 outer spring 303 are compressed, and the reaction force produced after No. 2 inner spring 301 and No. 2 outer spring 303 are compressed can carry out secondary vibration reduction to vibration force.

Embodiment 3

[0023] As a preferred embodiment of the present invention: the adjustment module 4 includes an electro-hydraulic push rod 401, and an extension spring 402 is installed on the inside of the electro-hydraulic push rod 401. When the electro-hydraulic push rod 401 is in operation, the electro-hydraulic push rod 401 drives the extension spring 402 prolongs or stretches, and electrohydraulic push rod 401 drives No. 2 inner spring 301, No. 2 outer spring 303 and No. 1 inner spring 202, and No. 1 outer spring 204 prolongs or shortens simultaneously, changes No. 2 inner spring 301, No. 2 outer spring 303 and The anti-vibration capabilities of the No. 1 inner spring 202 and the No. 1 outer spring 204 can achieve the purpose of adjusting the amplitude.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com