LED lamp installation device based on gravity stabilization

A technology of LED lamps and installation devices, which is applied in the direction of lighting devices, lighting auxiliary devices, lighting device components, etc., can solve the problems of increasing the cost of purchasing ladders and storage space, taking a long time, shaking, etc., to avoid collision damage to bulbs, The effect of shortening the installation operation time and reducing the hand-held alignment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

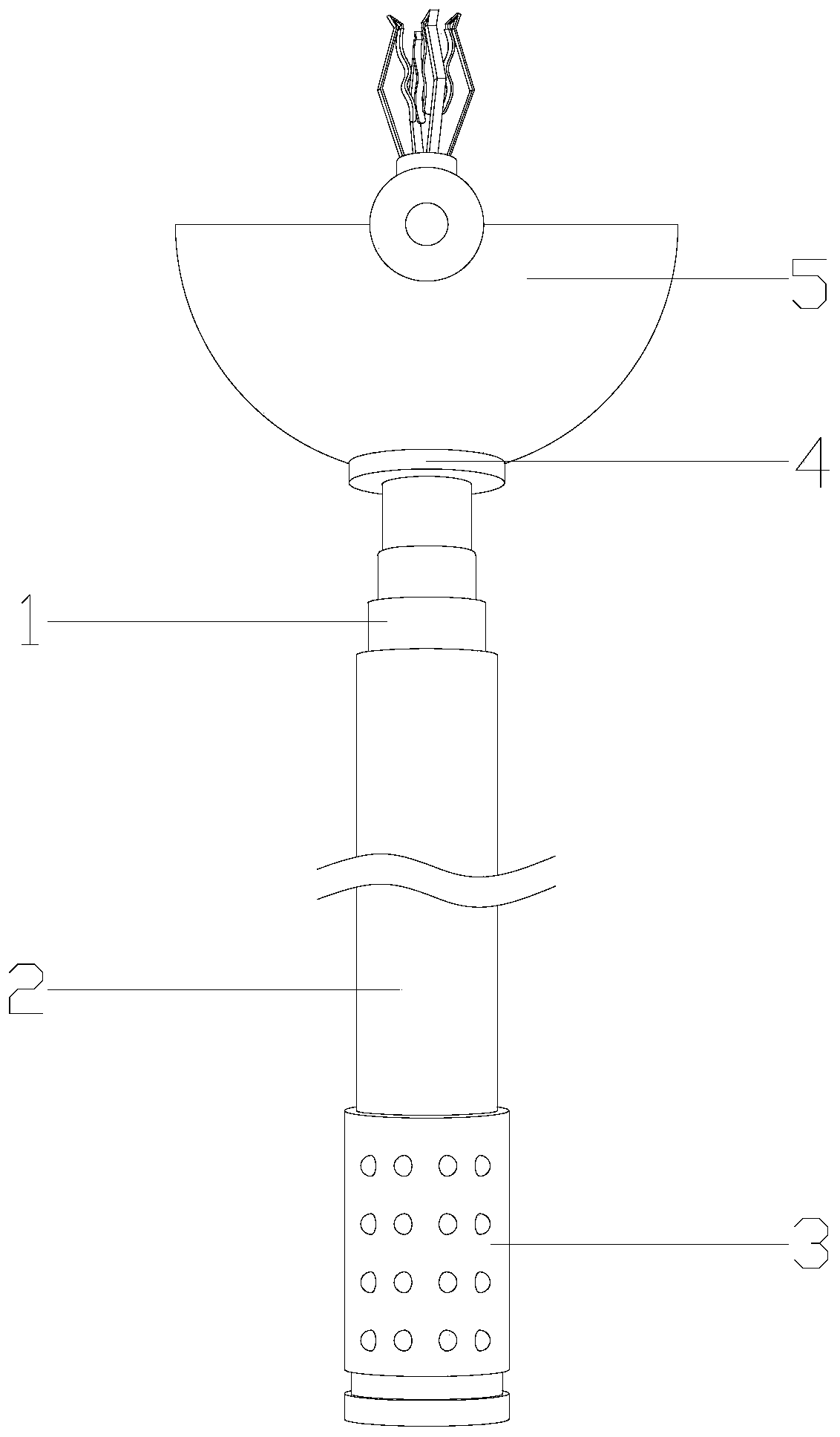

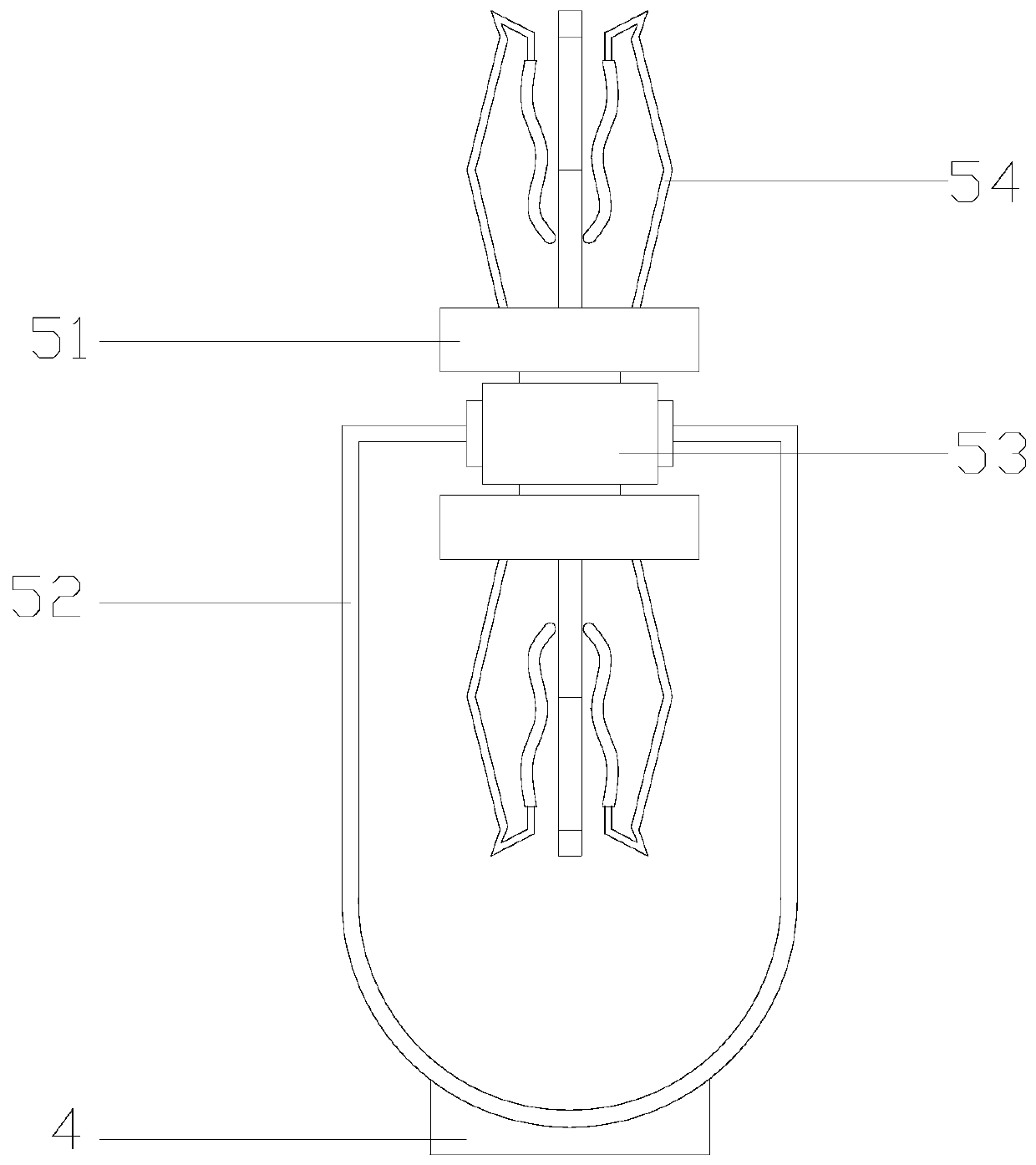

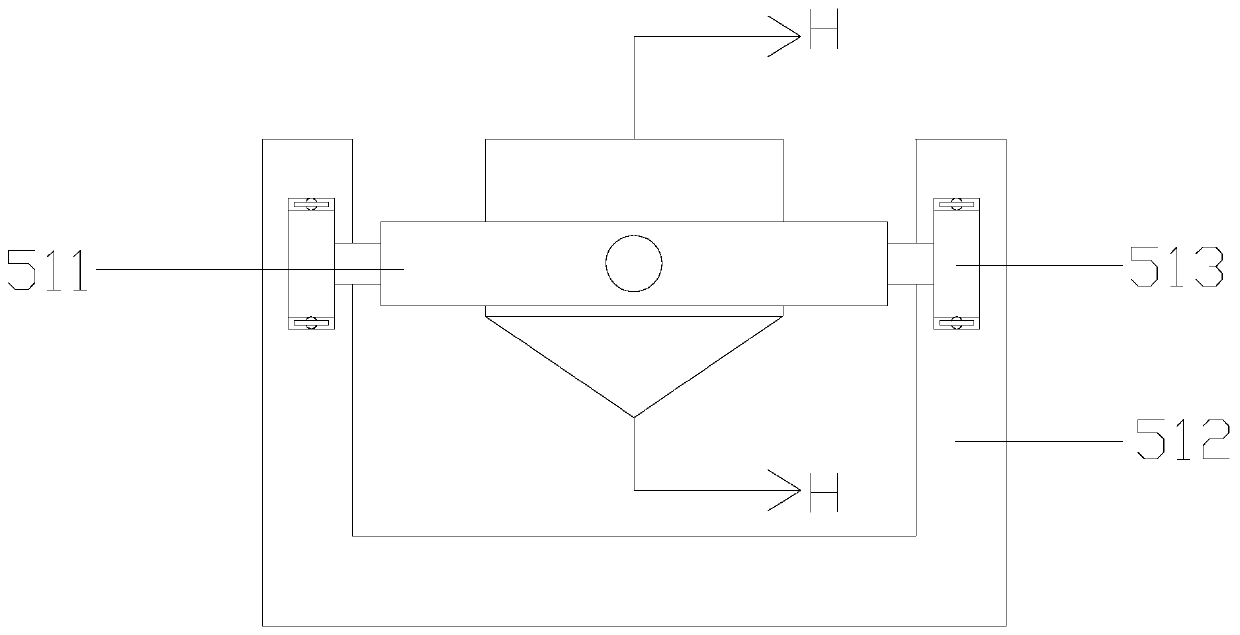

[0026] see Figure 1-Figure 2 , the present invention provides a stable LED lamp installation device based on gravity, the structure of which includes a telescopic rod 1, a telescopic rod sleeve 2, an anti-slip sleeve 3, a holder connection seat 4, and a light bulb fixing structure 5. The telescopic rod 1 and the telescopic rod The rod sleeve 2 is a concentric circle structure and adopts a gap fit. The inner wall of the anti-slip sleeve 3 is closely connected with the outer surface of the bottom of the telescopic rod sleeve 2, and the bottom of the holder connecting seat 4 is interlocked with the top of the telescopic rod 1. The bottom of the bulb fixing structure 5 is threadedly connected with the top of the holder connecting seat 4, and the bulb fixing structure 5 is composed of a fixing grip stabilizer 51, a fixing structure shell 52, a bulb converter 53, and a bulb fixing claw 54. The bottom of the fixed structure housing 52 is threadedly connected to the top of the holder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com