Novel heat exchanger capable of automatically adjusting heat exchange area and flow adjusting method

An automatic adjustment and heat exchange area technology, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problem of affecting subsequent processes, energy consumption of water pumps, and the inability of condensers to make changes according to real-time working conditions, etc. problem, to achieve the effect of precise regulation of heat exchange area and reduction of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

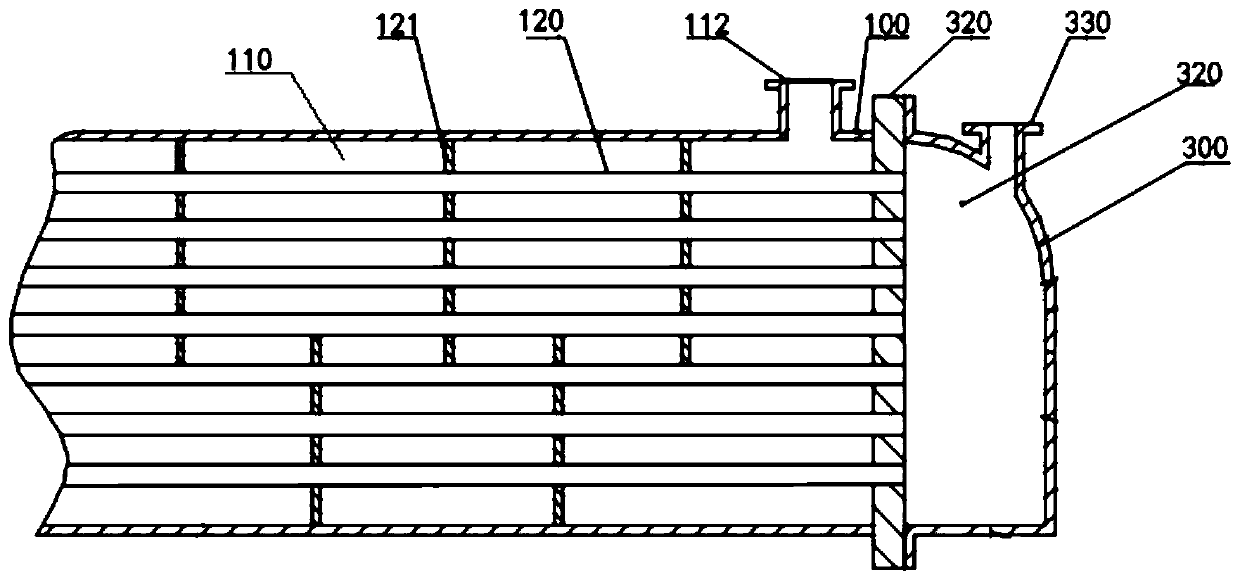

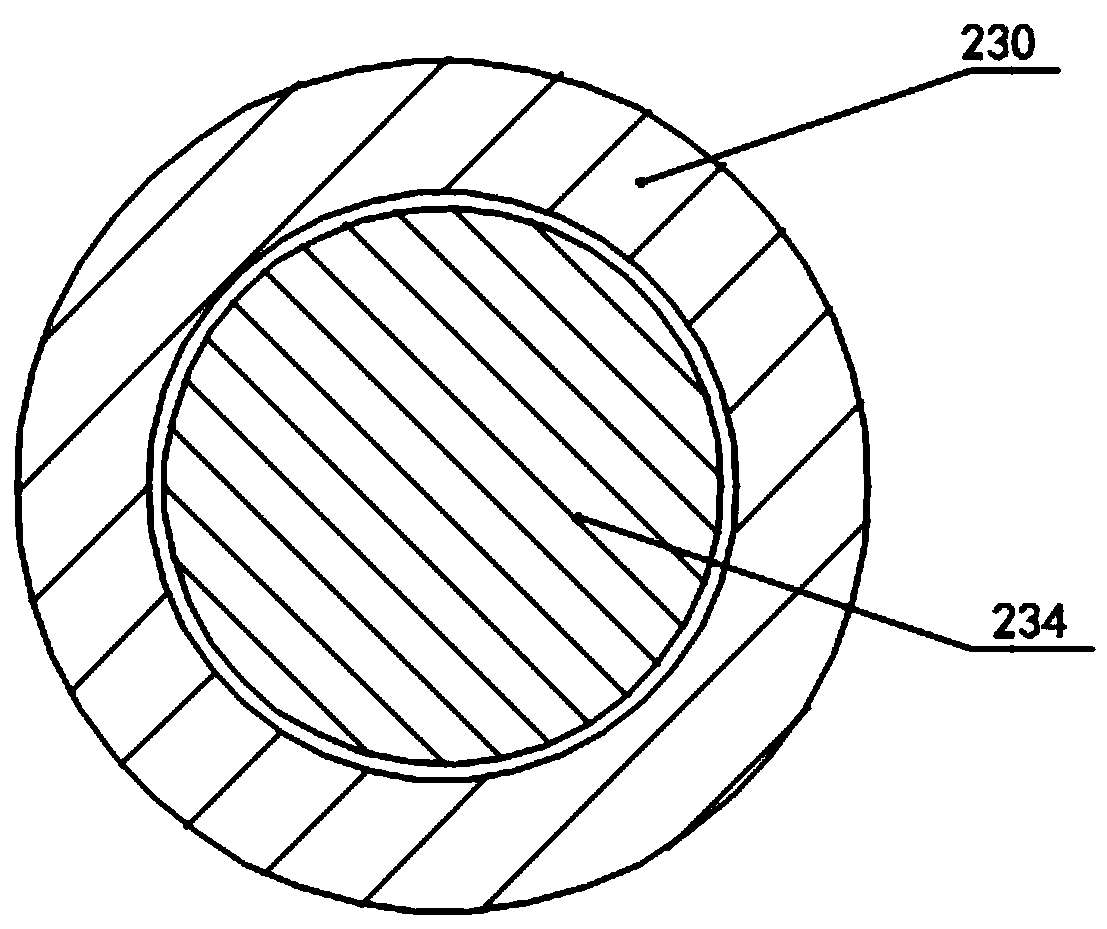

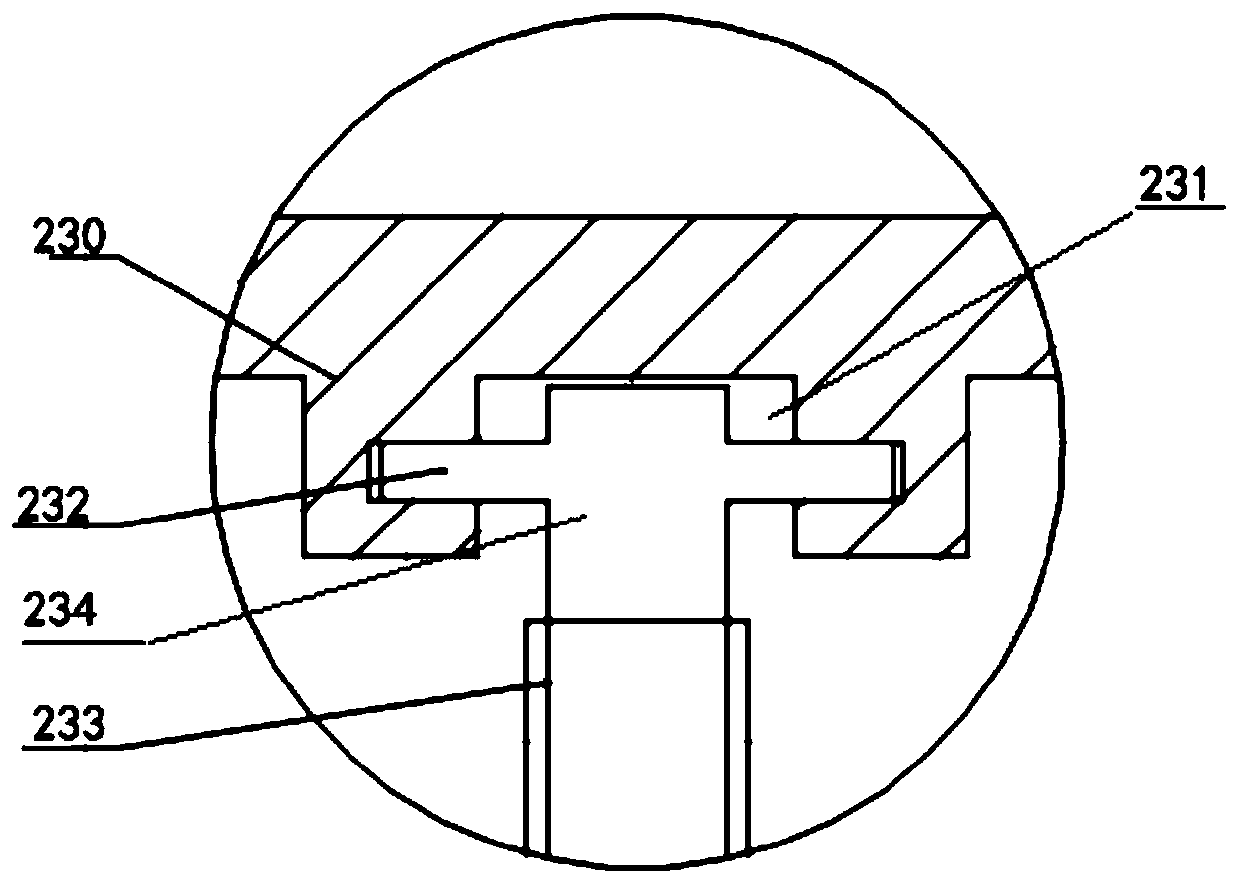

[0071] Such as Figure 1-6 As shown, the present invention provides a new type of heat exchanger that automatically adjusts the heat exchange area, including: a shell 100; and a first tube box 200 and a second tube box 300, which are symmetrically arranged on both sides of the shell 100 in the axial direction; A first sealing plate 210 and a second sealing plate 310 are respectively sealed between the axial sides of the housing 100 and the first tube box 200 and the second tube box 300, and the housing 100, the first tube box 200 and the second tube box 300 are sealed. The second pipe box 300 is divided into a shell chamber 110, a first pipe box chamber 220, and a second pipe box chamber 320; heat exchange tubes 120 are arranged in parallel at equal intervals in the shell 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com