Workshop air conditioner control method and system

A control method and air-conditioning technology, applied in heating and ventilation control system, control input related to air characteristics, space heating and ventilation control input, etc., can solve the problem that the air-conditioning control method of the factory cannot realize precise energy-saving control and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

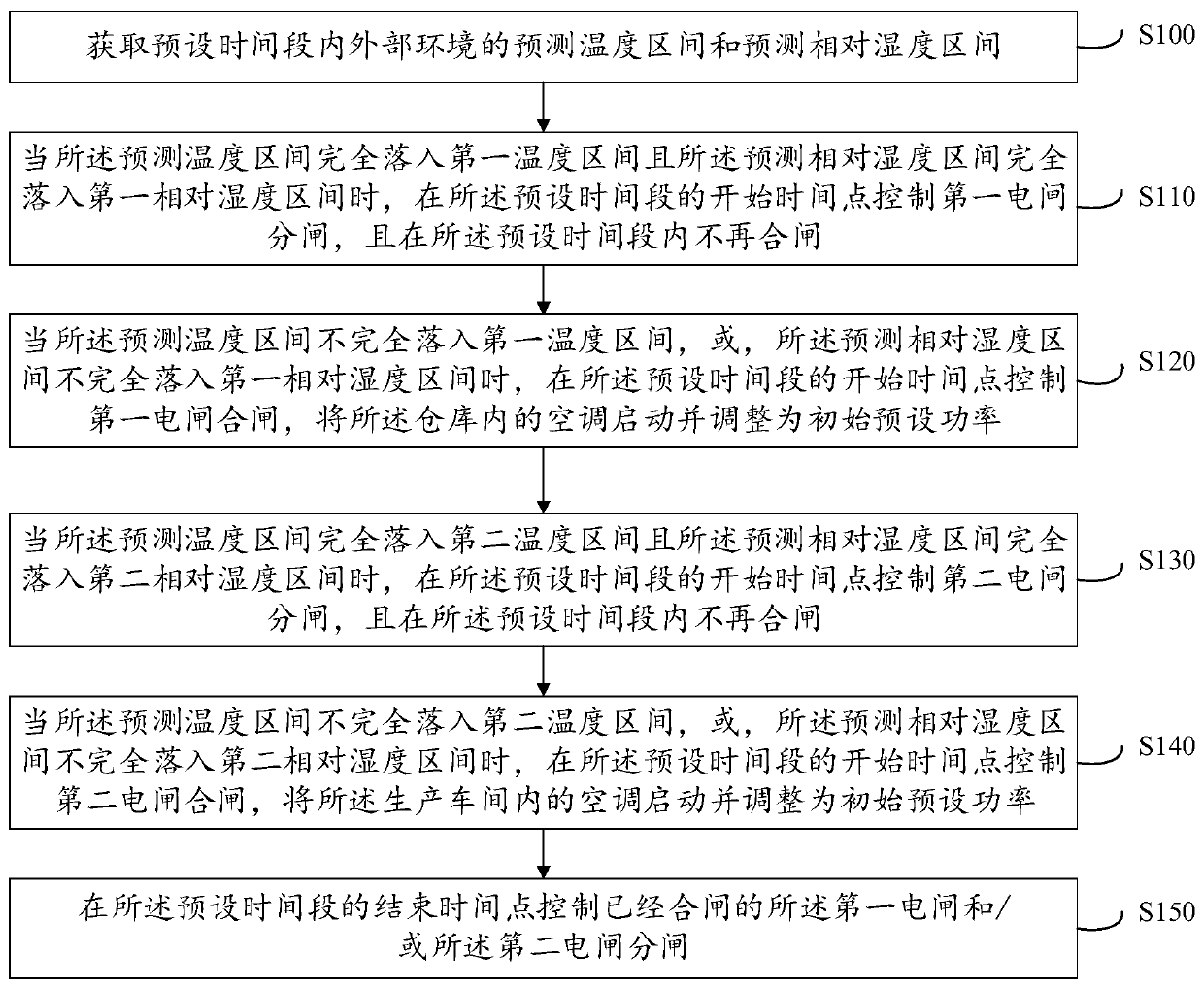

Method used

Image

Examples

no. 1 example

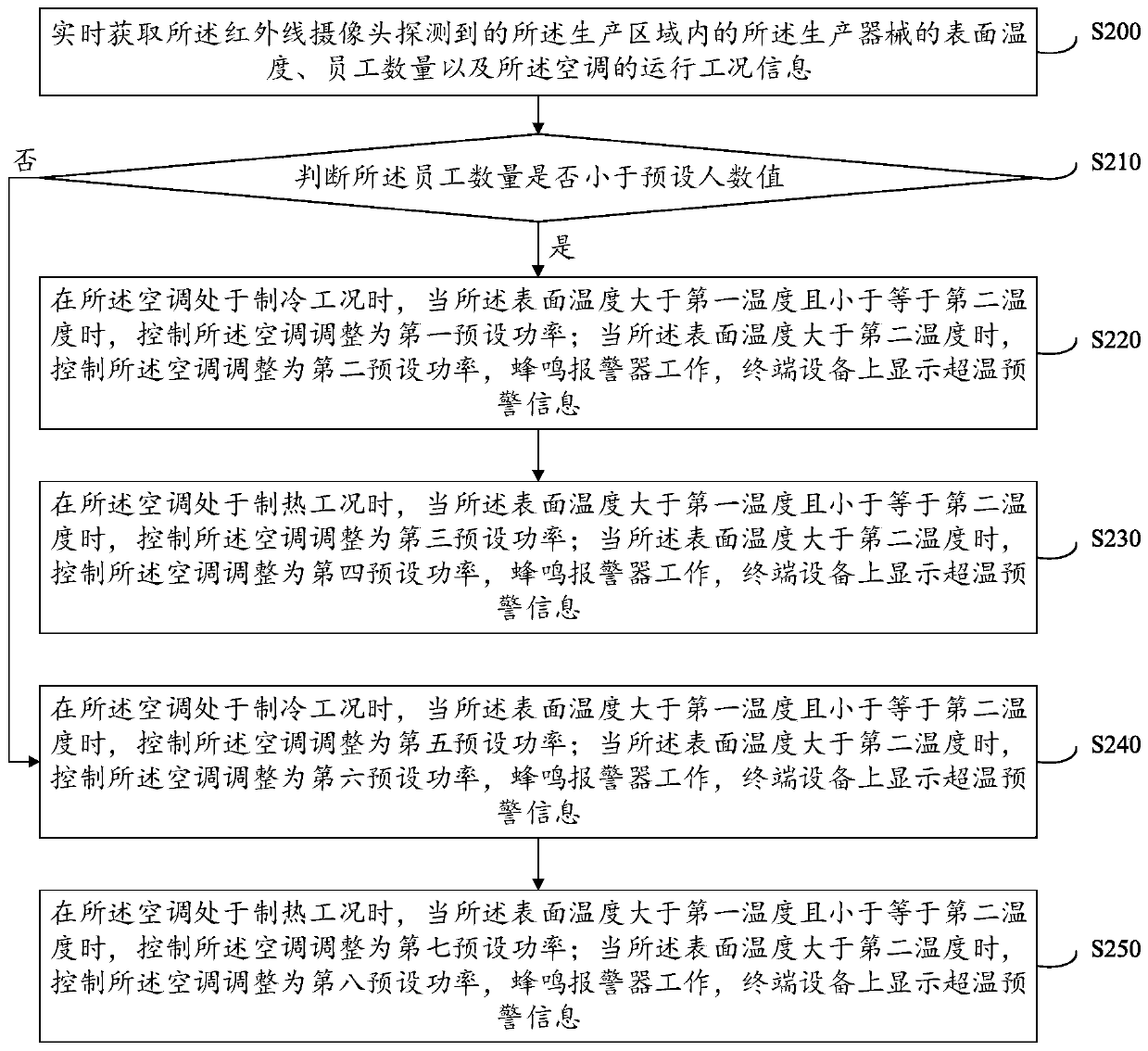

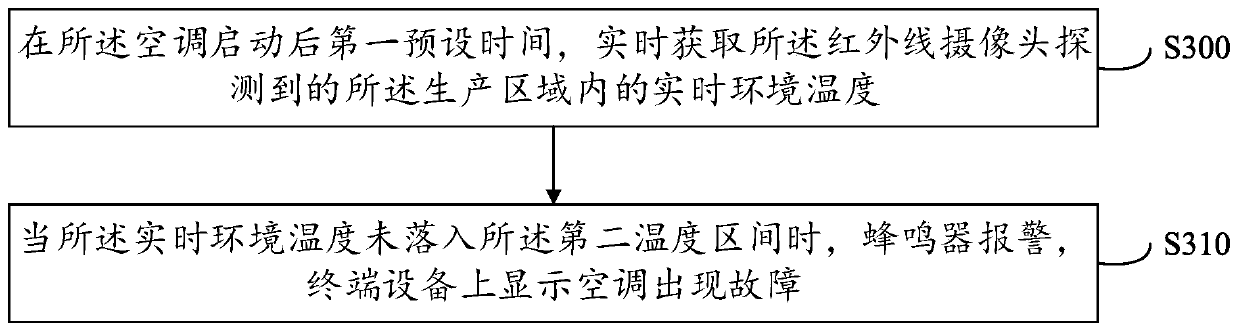

[0095] Please refer to figure 2 , figure 2 In the first embodiment of the method for controlling the air conditioner in a factory building according to the present invention, it is a schematic flow chart after the steps of starting and adjusting the air conditioner in the production workshop to the initial preset power; based on the first embodiment, it includes the following steps:

[0096] Step S200: Obtain in real time the surface temperature of the production equipment in the production area detected by the infrared camera, the number of employees, and the operating condition information of the air conditioner.

[0097] Step S210: Determine whether the number of employees is less than a preset number of people.

[0098] Specifically, due to the heating effect of the human body itself, the temperature of the area will rise when people gather; the preset number of people is the value when the number of employees in the area reaches the number of people who need to change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com