Dynamic surface defect optical detection system and method

A defect optics and detection system technology, applied in the field of optical detection, can solve the problems of inability to detect online, low precision, and high environmental requirements, and achieve the effect of improving work efficiency and compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

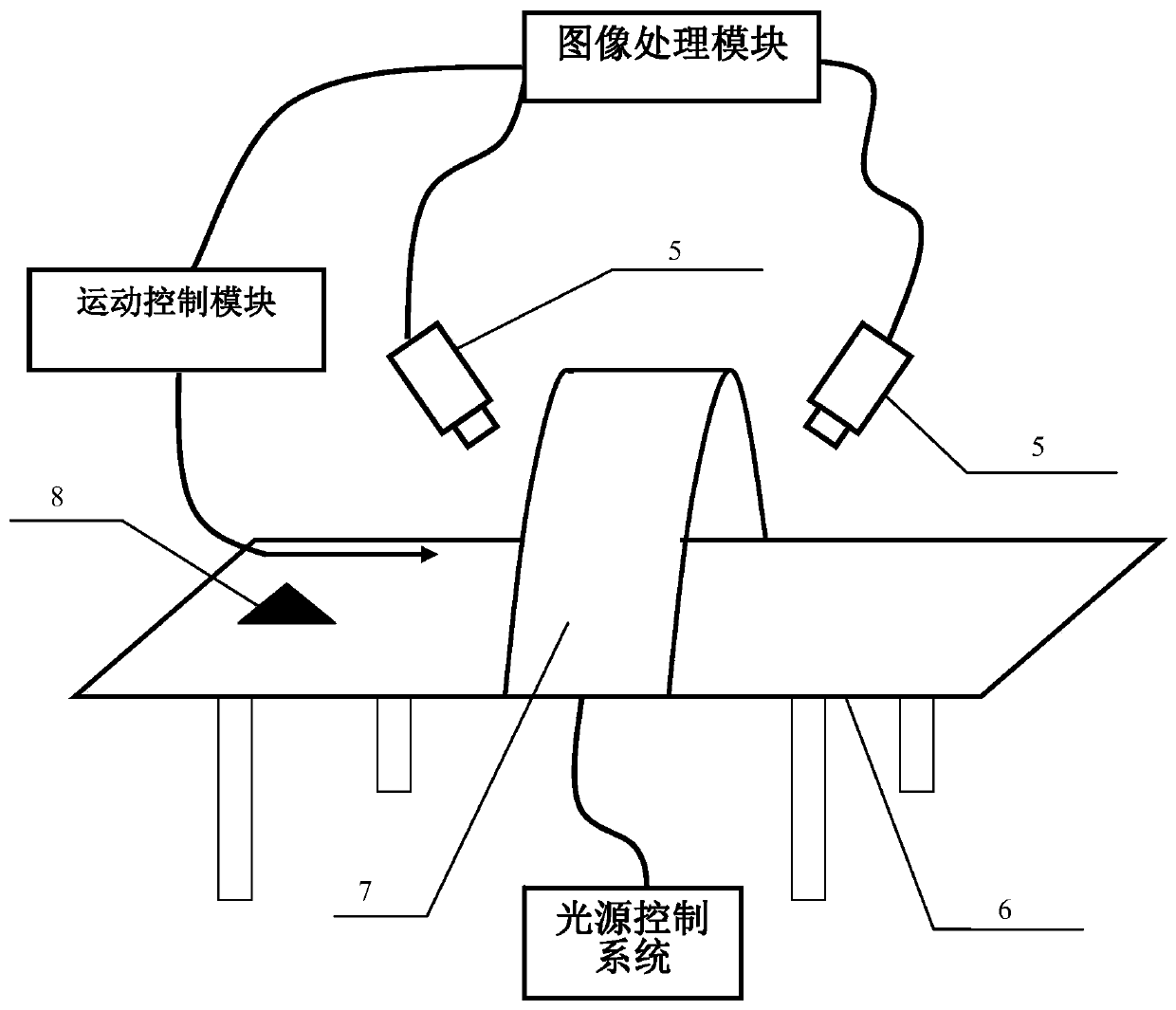

[0036] Such as image 3 with Figure 8 As shown, this embodiment provides a dynamic optical detection system for surface defects, including an image acquisition module 5, an image processing module, a diffuse reflection light source 7, and a transmission device for transmitting an object to be tested 8, and the transmission device includes a mobile platform 6 and a motion control module for controlling the movement of the mobile platform 6, the image processing module is connected with the image acquisition module 5 and the motion control module respectively, and the diffuse reflection light source 7 is arranged on the top of the mobile platform 6;

[0037] The motion control module is used to control the moving speed of the mobile platform 6 according to the control instruction sent by the image processing module, so that the object to be measured 8 enters the illumination area of the diffuse reflection light source 7;

[0038] The image acquisition module 5 is used to acq...

Embodiment 2

[0061] Such as Figure 9 As shown, the present embodiment provides a dynamic optical detection method for surface defects, comprising the following steps:

[0062] A1. Control the brightness of the diffuse reflection light source;

[0063] A2. Control the movement of the mobile platform so that the object to be measured passes through the illumination area of the diffuse reflection light source;

[0064] A3. Collect the image information of the object to be tested, judge whether to obtain the overall image of the object to be tested according to the image information according to the preset method, and if so, perform image defect analysis according to the image information; otherwise, return to continue to execute step A1.

[0065] The above method uses a diffuse reflection light source to realize the image acquisition module to completely photograph the object to be measured at a large angle, and solves the problem of photographing the object to be measured by adjusting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com