Automatic rising and falling wind resistance high pressure fine water mist fire extinguishing device

A high-pressure water mist and fire-extinguishing technology, applied in fire rescue and other directions, can solve the problems of reducing fire-extinguishing efficiency, being easily blown away by wind, and low fire-extinguishing performance, saving space, improving fire-extinguishing efficiency and performance, and fire-extinguishing efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

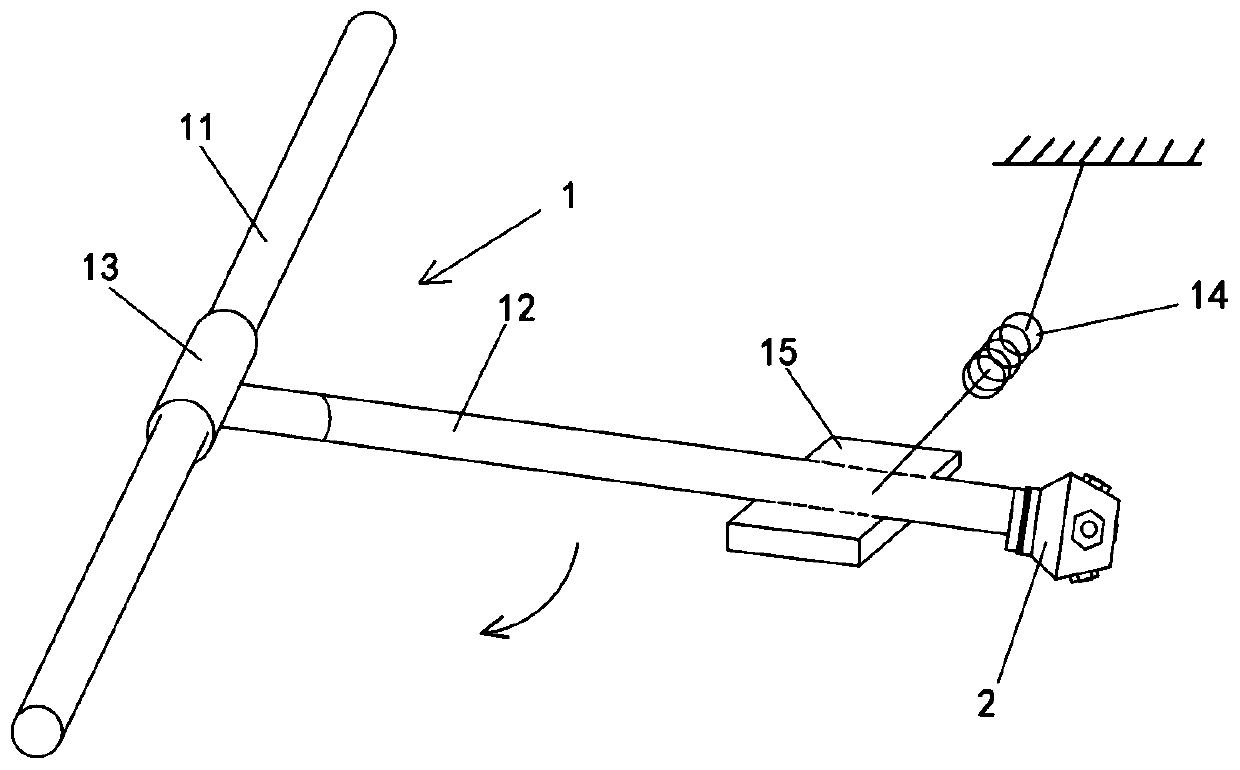

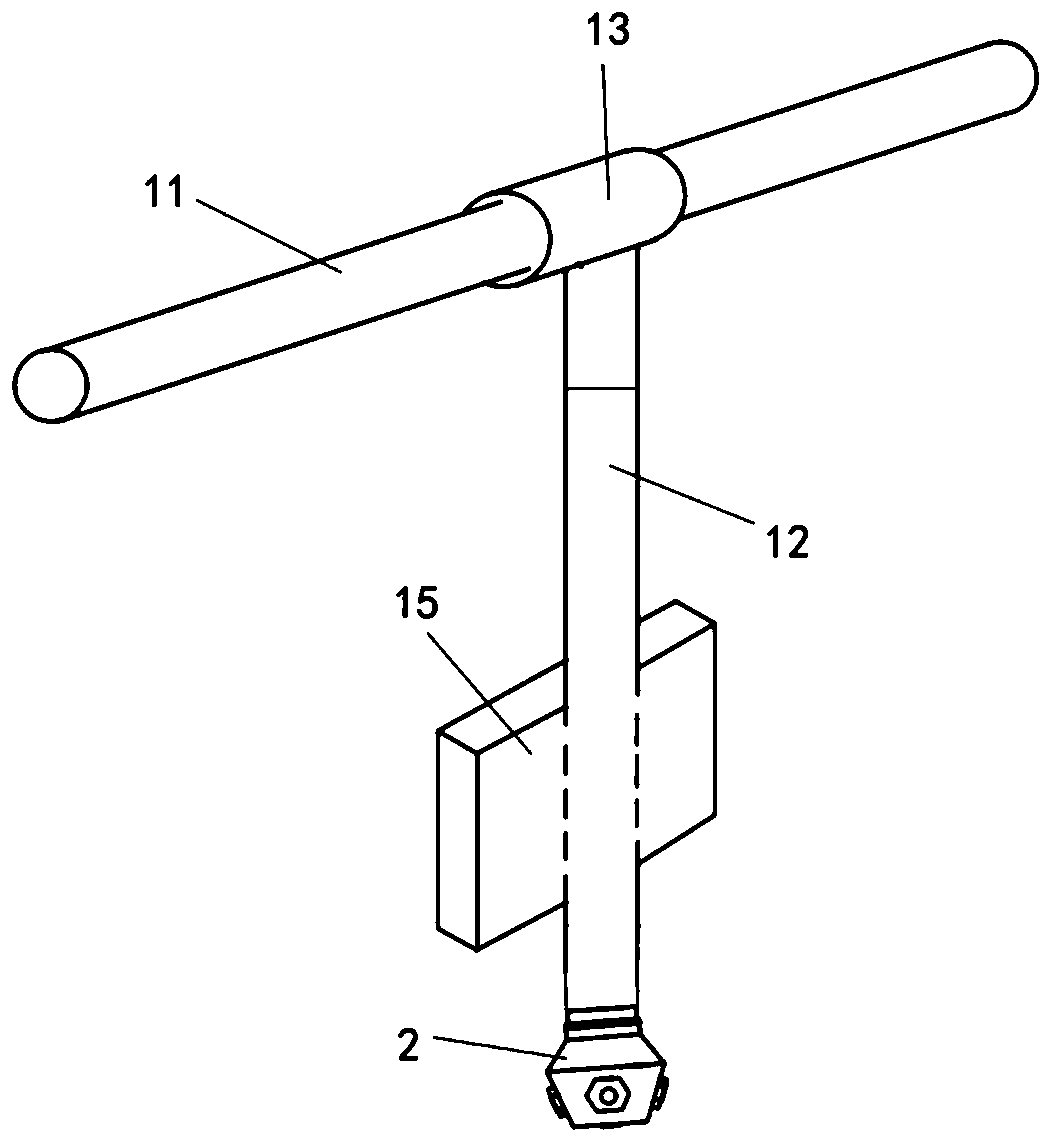

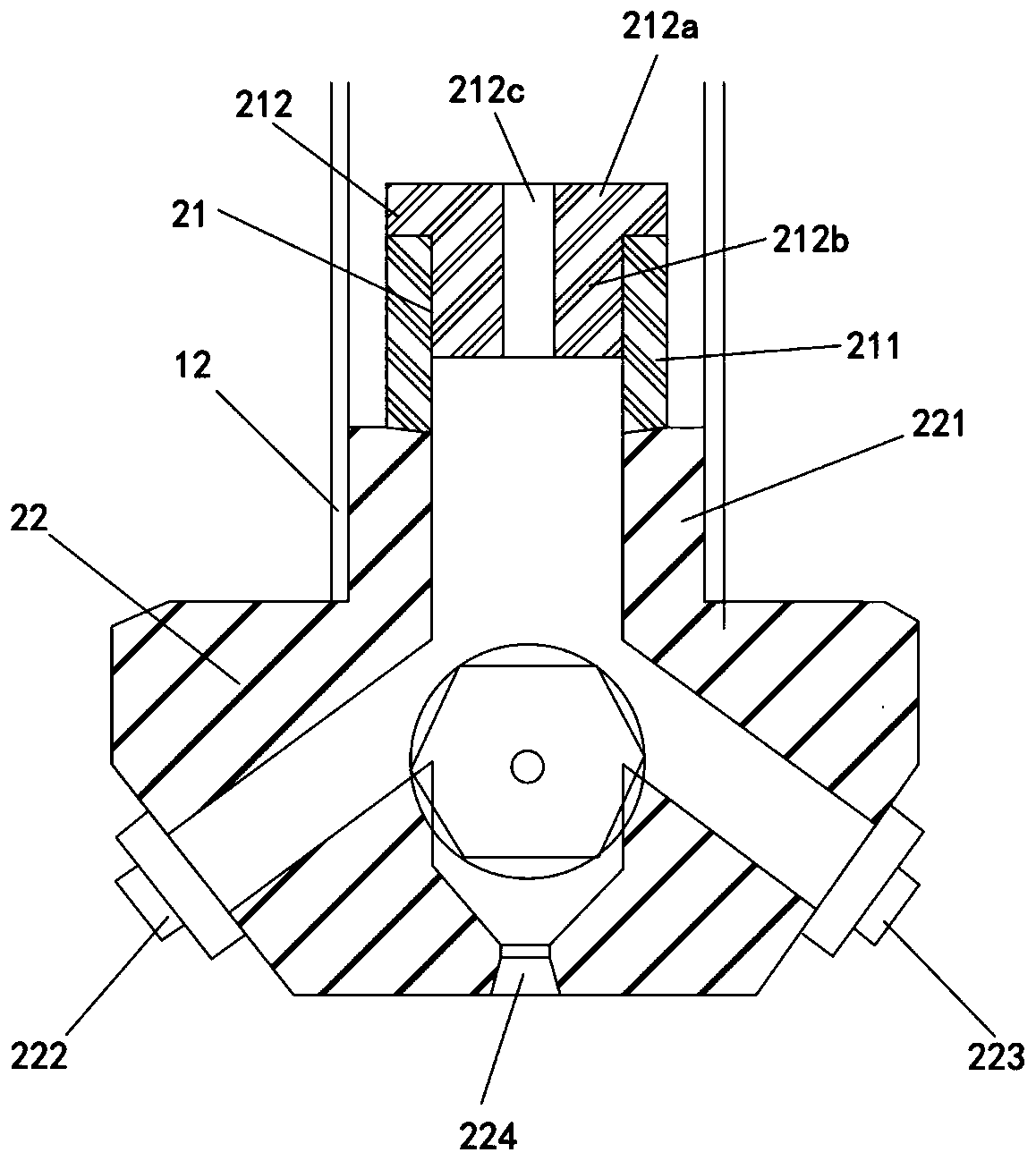

[0028] Such as figure 1 and figure 2 As shown, this embodiment provides an automatic wind-resistant high-pressure water mist fire extinguishing device, including a lifting mechanism 1 and a fire extinguishing nozzle 2 .

[0029] Lifting mechanism 1 comprises main water pipe 11 , branch water pipe 12 , T-shaped three-way pipe 13 , spring 14 and water storage tank 15 . The main water pipe 11 is connected to both ends of the T-shaped three-way pipe 13 in the transverse direction through an existing rotary sealing method, so that the T-shaped three-way pipe 13 can rotate along the axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com