Servo deviation adjustment rod sealing and hydraulic driving blowout preventing integrated device

A technology of polished rod sealer and sealed box body, which is applied in the directions of sealing/isolation, wellbore/well components, earth-moving drilling, etc., which can solve the inconvenient installation and removal of sealing packing, and the absence of deviation adjustment mechanism and centralization mechanism. , the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

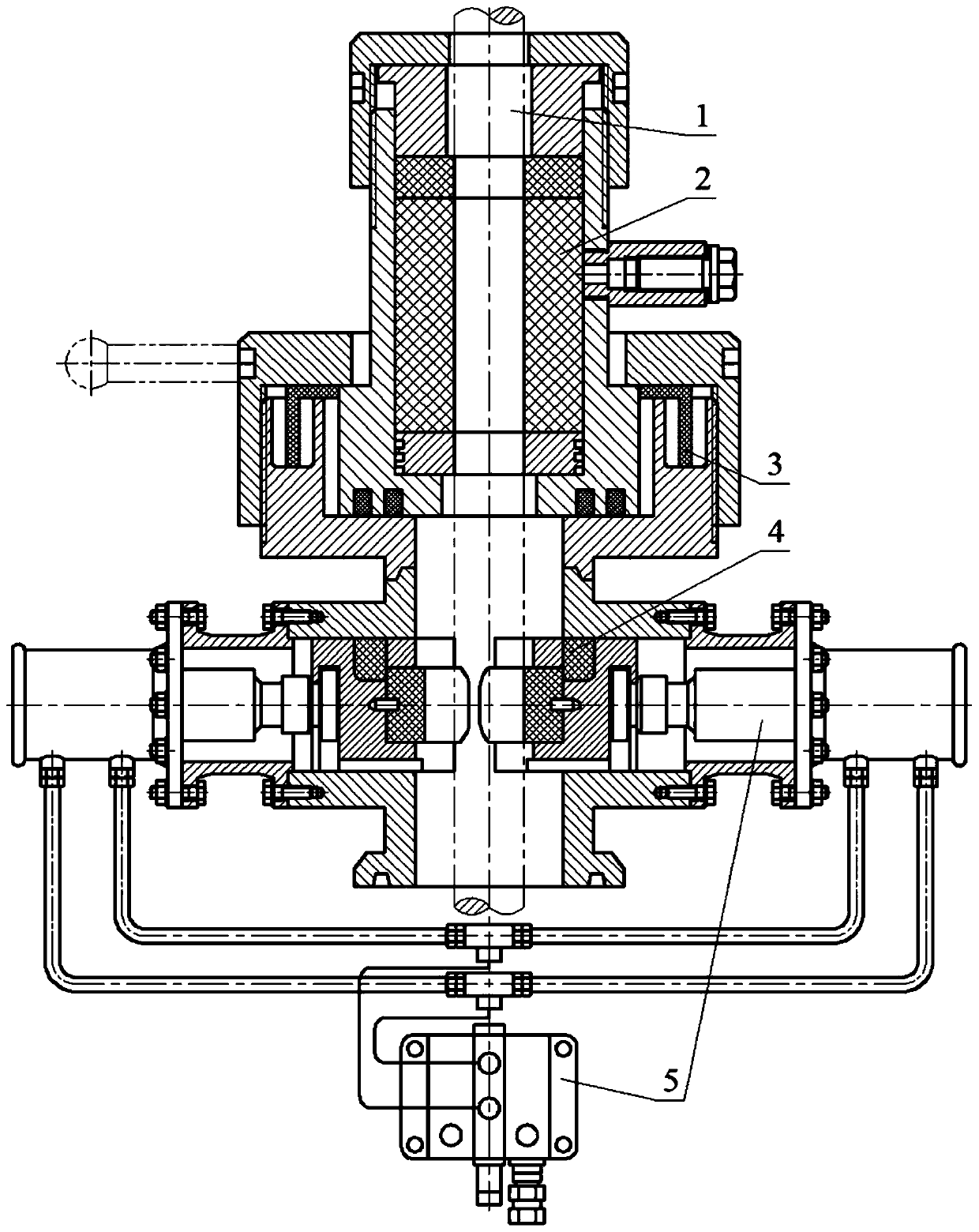

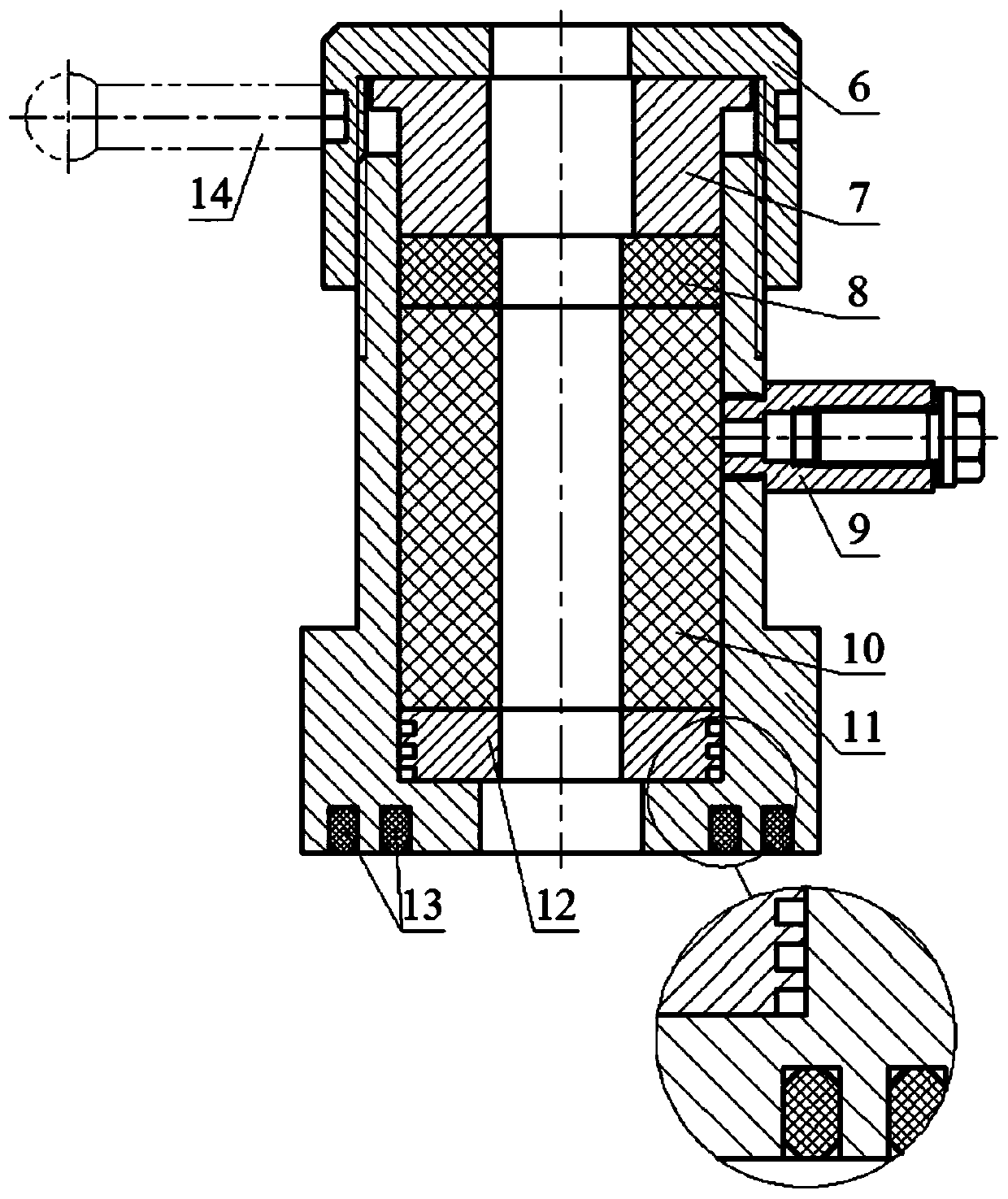

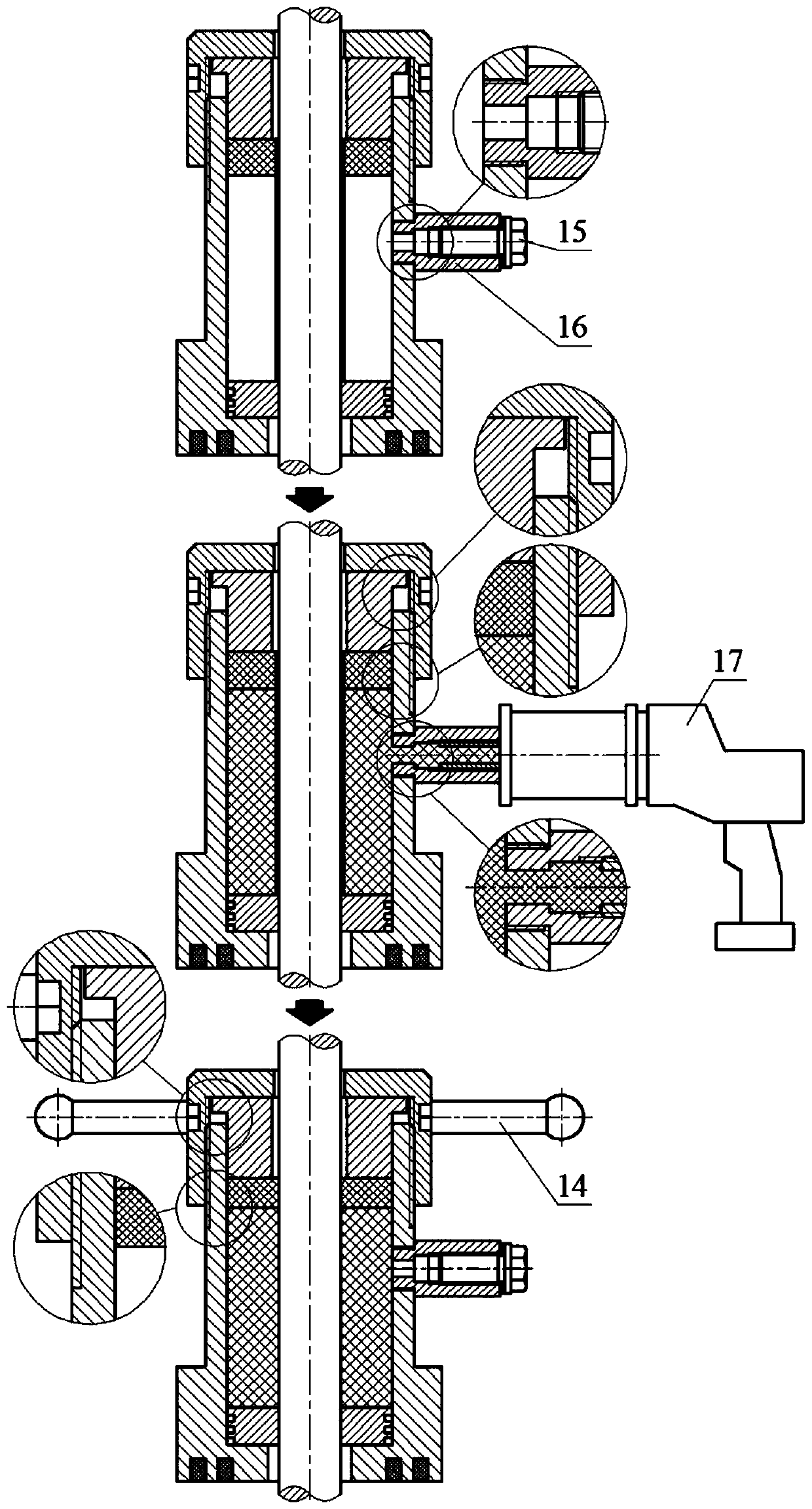

[0046] exist figure 1 Among them, the integrated device for sealing and liquid-driven anti-blowout of the polarizing rod with dynamic adjustment is composed of a polished rod sealer 2, a follow-up deflection adjuster 3, a snap-in BOP 4 and a hydraulic drive force device 5. The injection integrated device is based on the glue injection packing, rectangular sealing ring and double sealing ring of the polished rod sealer 2, the L-shaped sealing ring of the follower deflection adjuster 3, and the rod sealing core and shell sealing core of the buckle blowout preventer 4, Combined with the power provided by the hydraulic driving force device 5, the radial follow-up sliding deviation adjustment of the sucker rod 1 at the wellhead, the double-stage non-metallic dynamic seal and the radial precision snap-fit sliding blowout prevention operation are realized.

[0047] exist figure 1 Among them, the integrated device for sealing the polarizing rod with dynamic adjustment and liquid dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com