Sand prevention and filling system of large casing well

A casing well and sand filling technology, applied in casing, wellbore/well valve device, drill pipe, etc., can solve the problem of not being able to retreat, and achieve the effect of avoiding sand plugging and ensuring water-sand ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

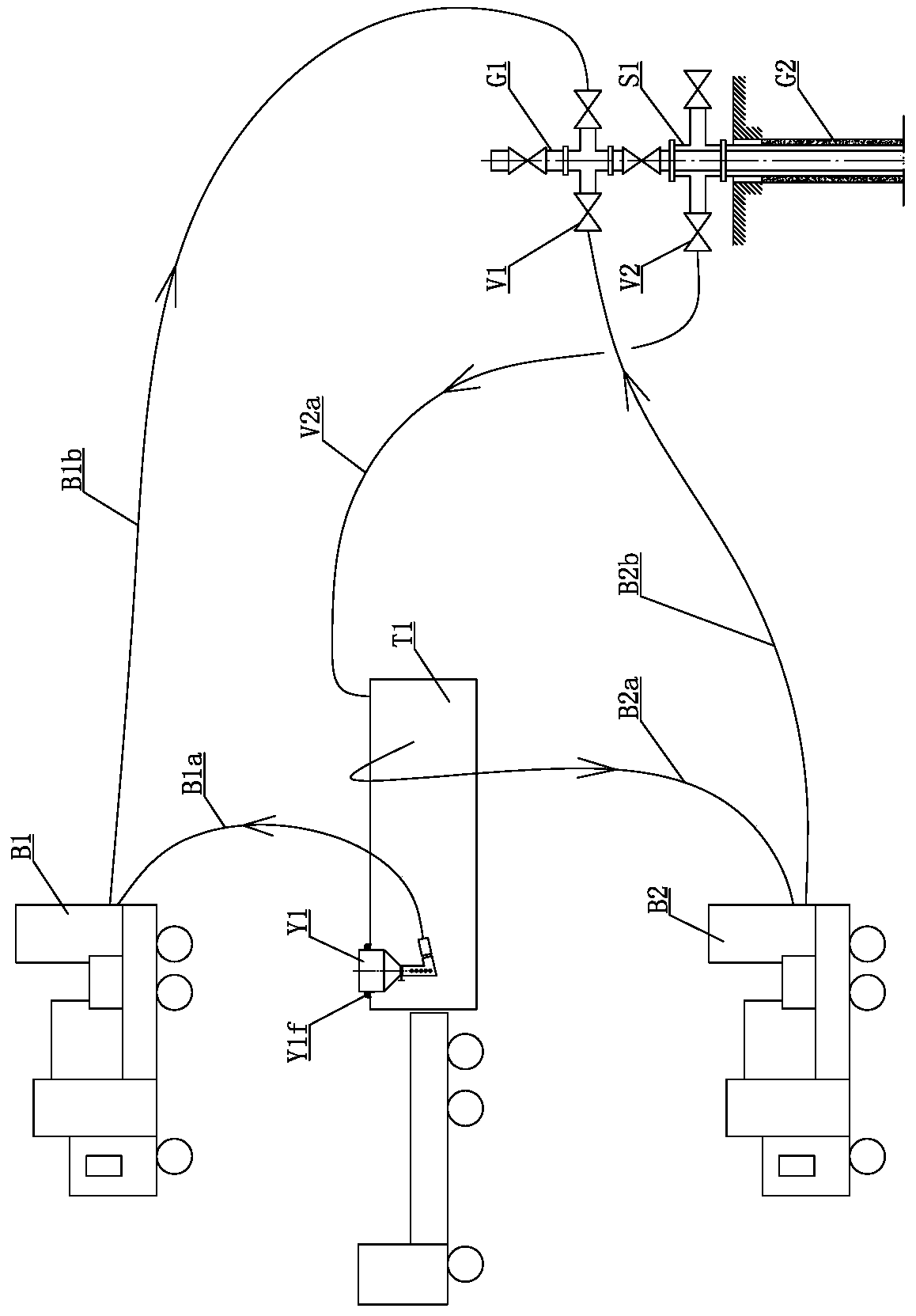

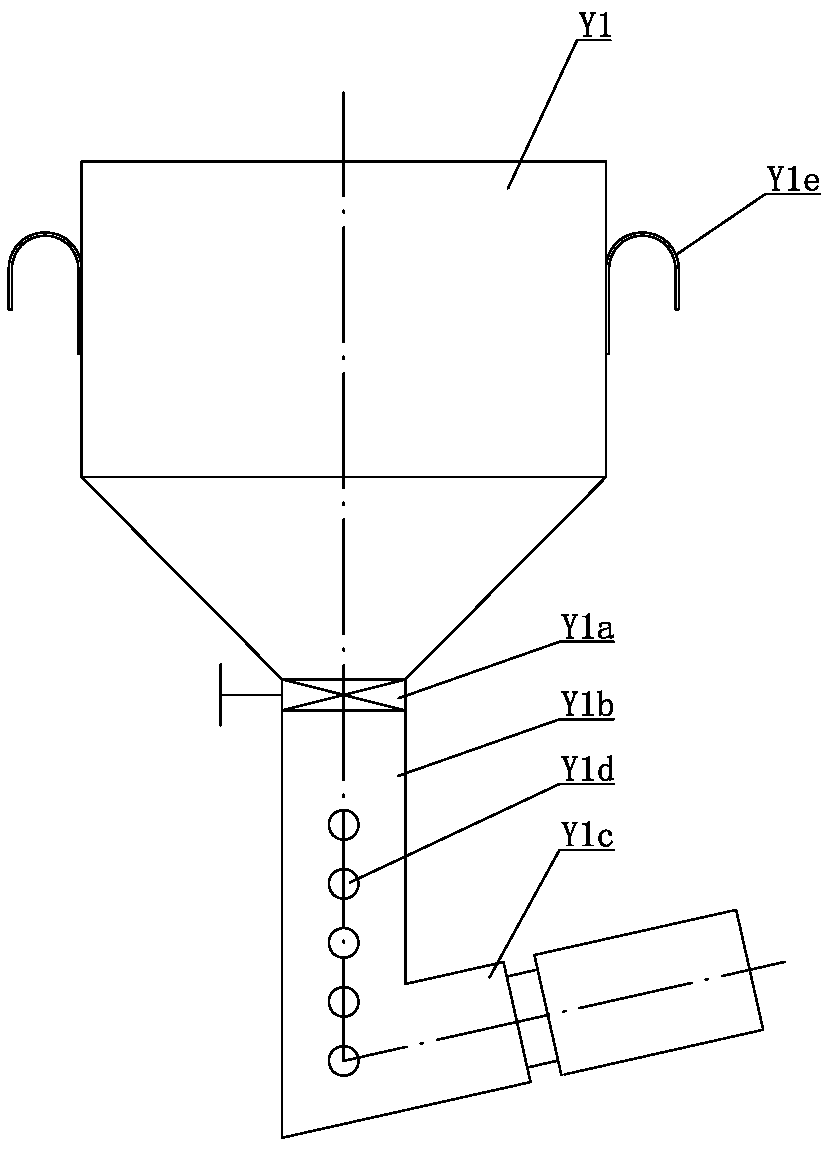

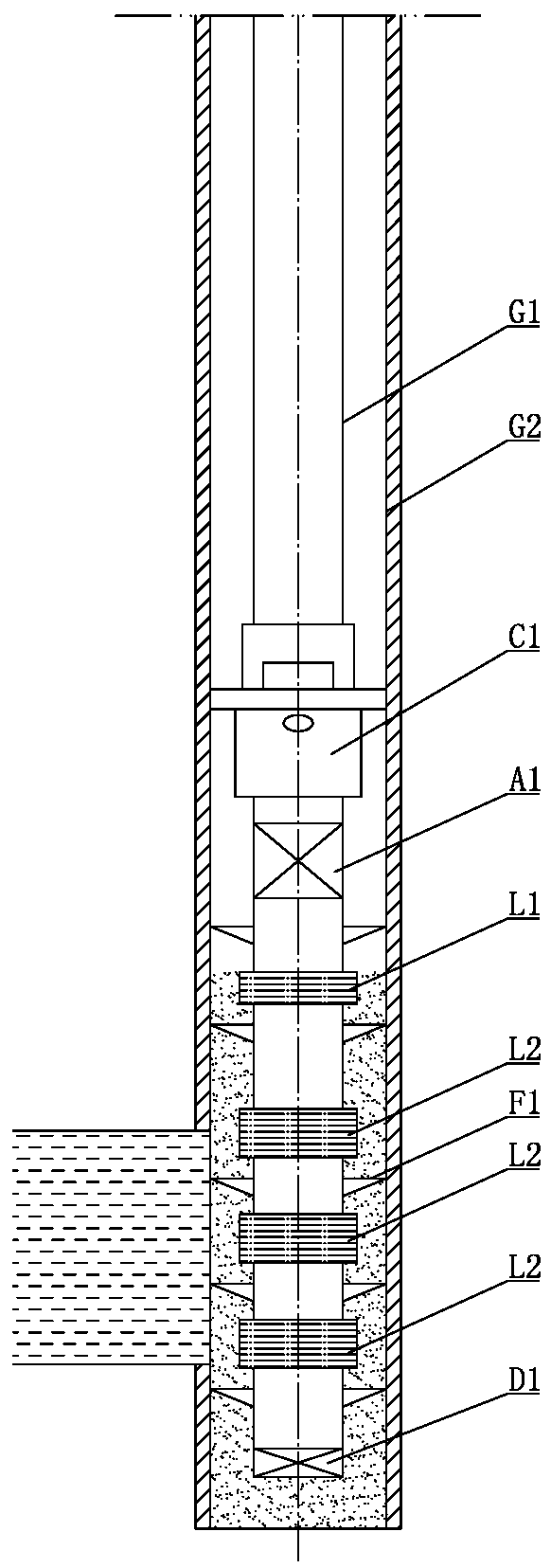

[0033] Such as figure 1 , figure 2 As shown, the sand control and sand filling system for large cased wells of the present invention, the ground facilities include a large tank T1, a main pump truck B1, an auxiliary pump truck B2, a sand filling funnel Y1, and a cross S1 located at the wellhead. The center of S1 passes through, and the left and right sides of the four-way S1 are respectively connected with the casing gate V2 connected with the annulus of the casing G2, and the upper sides of the oil pipe G1 are respectively connected with the oil pipe gate V1, and the bell mouth of the sand filling funnel Y1 There are at least two hooks Y1e welded on the outer periphery, and the hooks Y1e are respectively suspended on the support rods Y1f, and each support rod Y1f is respectively across the upper port of the large tank T1, and the throat of the sand filling funnel Y1 is equipped with a sand filling adjustment door Y1a, There are multiple funnel permeable holes Y1d distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com