Horizontal well drilling and fracturing completion string and its technology

A horizontal well and WOB technology, applied in the field of oil and gas field exploration and development, can solve the problems of inability to meet the technological requirements of large-scale volume fracturing, well control risks, environmental pollution caused by blowout, and increase in the development cost of horizontal wells, thereby reducing Sewage storage capacity, reduce the risk of construction sticking, and speed up the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

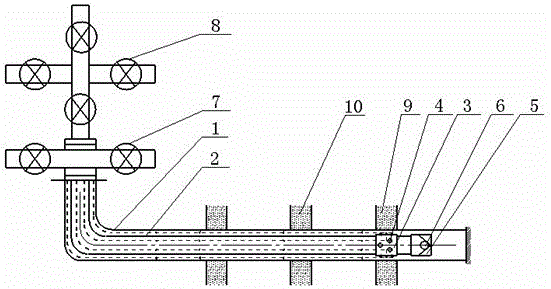

[0042] Such as figure 1As shown in the schematic diagram of the pipe string structure, the oil pipe 2 is sleeved in the casing 1, and the lowermost end of the oil pipe 2 is arranged with a hydraulic spray gun 3. The side of the hydraulic spray gun 3 is a spray gun hole, and the bottom is a ball seat 5 that can place a steel ball 6. The wellhead ends of casing 1 and tubing 2 are provided with casing valve 7 and tubing valve 8 respectively.

[0043] Among them, the ball seat 5 is a gradually shrinking bell-shaped structure, and the diameter of the lowermost bell mouth is smaller than the diameter of the steel ball 6. When sandblasting and perforation is required, the steel ball 6 is put into the ball seat 5 from the oil pipe 2 to form a single flow valve, so that the liquid for sandblasting and perforating is ejected from the hole 4 of the spray gun to meet the technical requirements of sandblasting and perforating; when sand-adding fracturing is to be performed, the pressure in...

Embodiment 2

[0046] This horizontal well drilling and fracturing completion process includes the following steps:

[0047] a. Lower the tubing 2 to the bottom of the well, perform large-volume reverse circulation flushing on the casing 1, and perform a pressure test on the casing 1 to meet the technical standard of flushing;

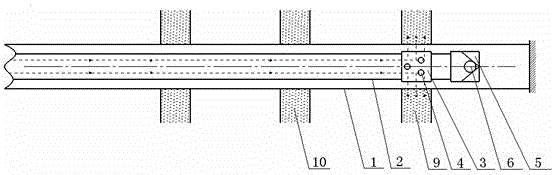

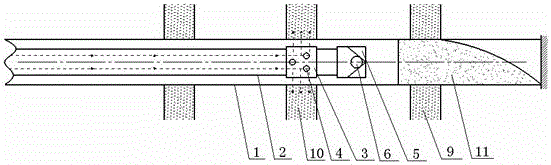

[0048] b. Lift the tubing 2 to the position of the first section 9 of the horizontal well construction, see figure 2 ;

[0049] c. Throw the steel ball 6 inward from the upper port of the oil pipe 2, and pump the steel ball 6 to the ball seat 5, so that the spray liquid in the oil pipe 2 can only be sprayed from the hole 4 of the spray gun. At this time, the ground construction The pressure of the pump can reach the hydraulic jet construction pressure; open the tubing valve 8, and perform single or multi-cluster hydraulic jetting on the first section 9 in the horizontal well through the tubing 2;

[0050] d. After the injection is completed, close the casing valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com