A method for fracturing through mudstone layers in horizontal wells

A horizontal well and mudstone technology, applied in the field of oil production technology in oil fields, can solve the problems of construction failure, narrow crack width and high fracture pressure, and achieve the effect of avoiding sand plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

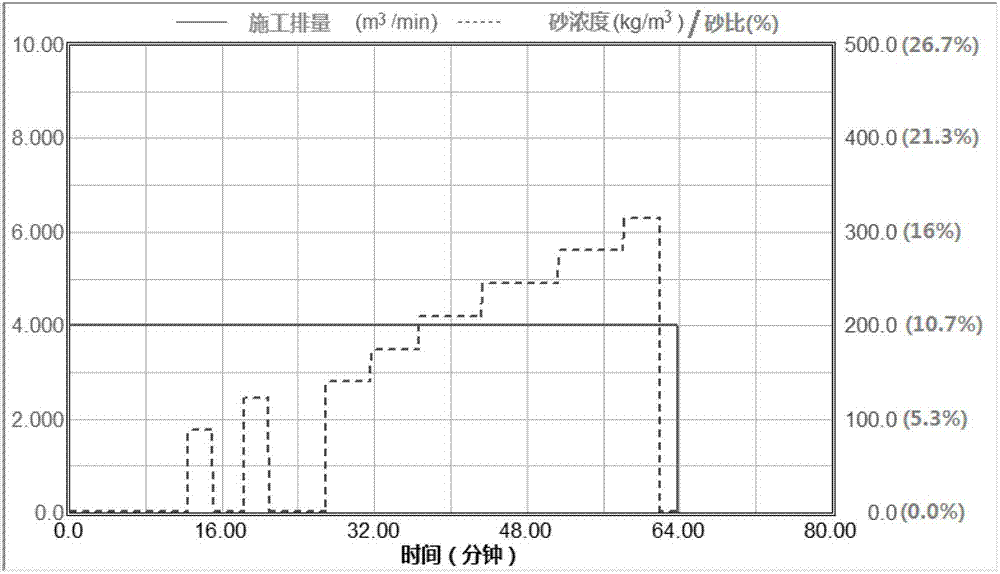

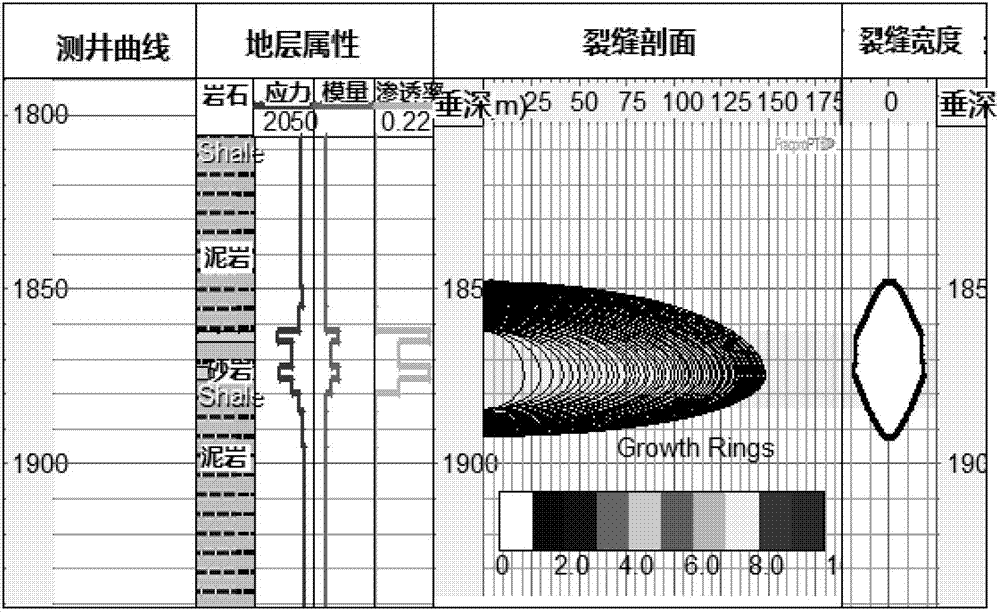

[0044]The mudstone penetration fracturing method of the horizontal well in this embodiment: for the fracturing characteristics of unknown formations, the step test fracturing technology is firstly used to analyze the extension characteristics of mudstone fractures, and to understand the extension pressure, closure pressure and the fluid loss characteristics of the formation. For the main sand fracturing construction, the following technical measures are taken, and the pumping procedures are as follows: figure 1 shown.

[0045] In the initial stage of fracturing, start the fracturing crew quickly, and inject fracturing fluid with a displacement of 4.0m within 15 seconds 3 / min, the pressure is suppressed in the wellbore, causing the formation to crack rapidly.

[0046] In the pre-fluid stage, the pre-fluid is injected to expand the fracture, and the injection volume of the pre-fluid is 45% (v / v) of the total injection volume of the fracturing fluid, so that the fracture is ful...

Embodiment 2

[0050] For the main sand fracturing construction, take the following technical measures:

[0051] In the initial stage of fracturing, start the fracturing crew quickly, and inject fracturing fluid displacement to reach 4.5m within 12 seconds 3 / min, the pressure is suppressed in the wellbore, causing the formation to crack rapidly.

[0052] In the pre-fluid stage, the pre-fluid is injected to expand the fracture, and the injection volume of the pre-fluid is 45% (v / v) of the total injection volume of the fracturing fluid, so that the fracture is fully extended in length and height, providing support The laying of the agent provides conditions and expands the oil drainage area of the fracture. At the same time, in the preflush stage, 5% (v / v) and 7% (v / v) ceramsite slugs with a particle size between 40 and 70 mesh were added to the preflush to polish the crack wall.

[0053] In the sand-carrying liquid stage, the sand ratio is 8%-10%-12%-14%-16%-18% (v / v) in a stepwise manne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com