A manual brick removal machine

A brick machine and brick-enclosing technology, which is applied in the field of manual brick-picking machines, can solve problems such as poor brick-picking effect and small pulling force, and achieve the effects of compact structure, fast and reliable action, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

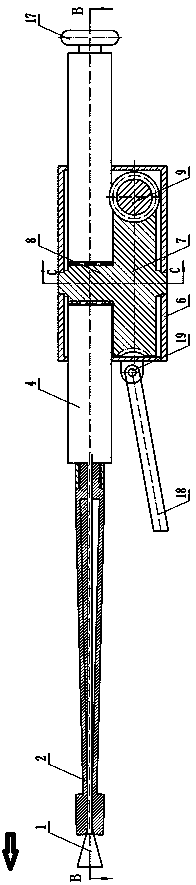

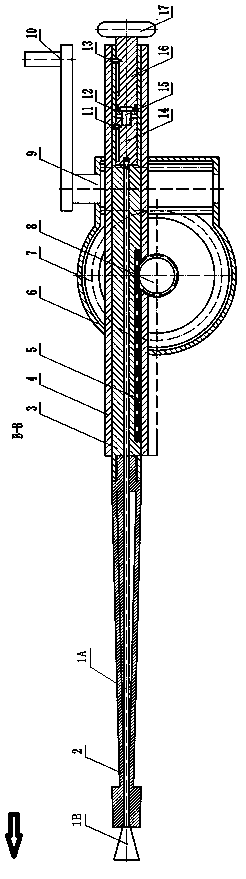

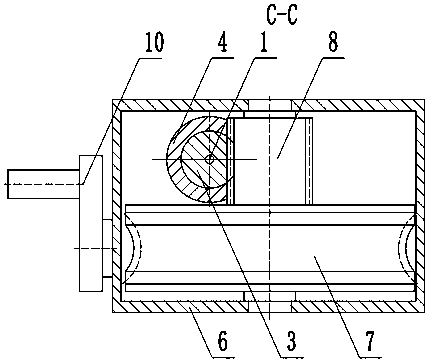

[0033] Embodiment I of the present invention: the present invention is used for the oxygen lance brick demolition with aperture. Such as Figure 1 ~ Figure 3 As shown, the position and the direction of motion of each part in the definition figure are the position and the direction shown in the figure; the present invention includes a hook device, a force device; The support sleeve 4 and the casing 6 are fixedly connected; the coaxial sliding fit in the support sleeve 4 is provided with a pull sleeve 3, and the pull sleeve 3 is used to connect and install the hook device, and transmit the force generated by the force device to the pull hook device;

[0034] The hook device includes a hook mechanism and a hook expansion mechanism; the hook mechanism includes a pull tube 2; the end of the pull tube 2 close to the tapered wedge 1B is provided with two or more axial openings, preferably four openings; Wherein the draw tube 2 is an elastic structure whose tail is connected, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com