System and method for automatic detection of implement working width

A technology of working width and automatic detection, applied in land preparation methods, agriculture, applications, etc., can solve problems such as inaccurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention described below are not intended to be exhaustive or to limit the disclosure to the precise forms described in the following detailed description. Rather, the embodiments were chosen and described in order to enable others skilled in the art to recognize and understand the principles and practice of the present disclosure.

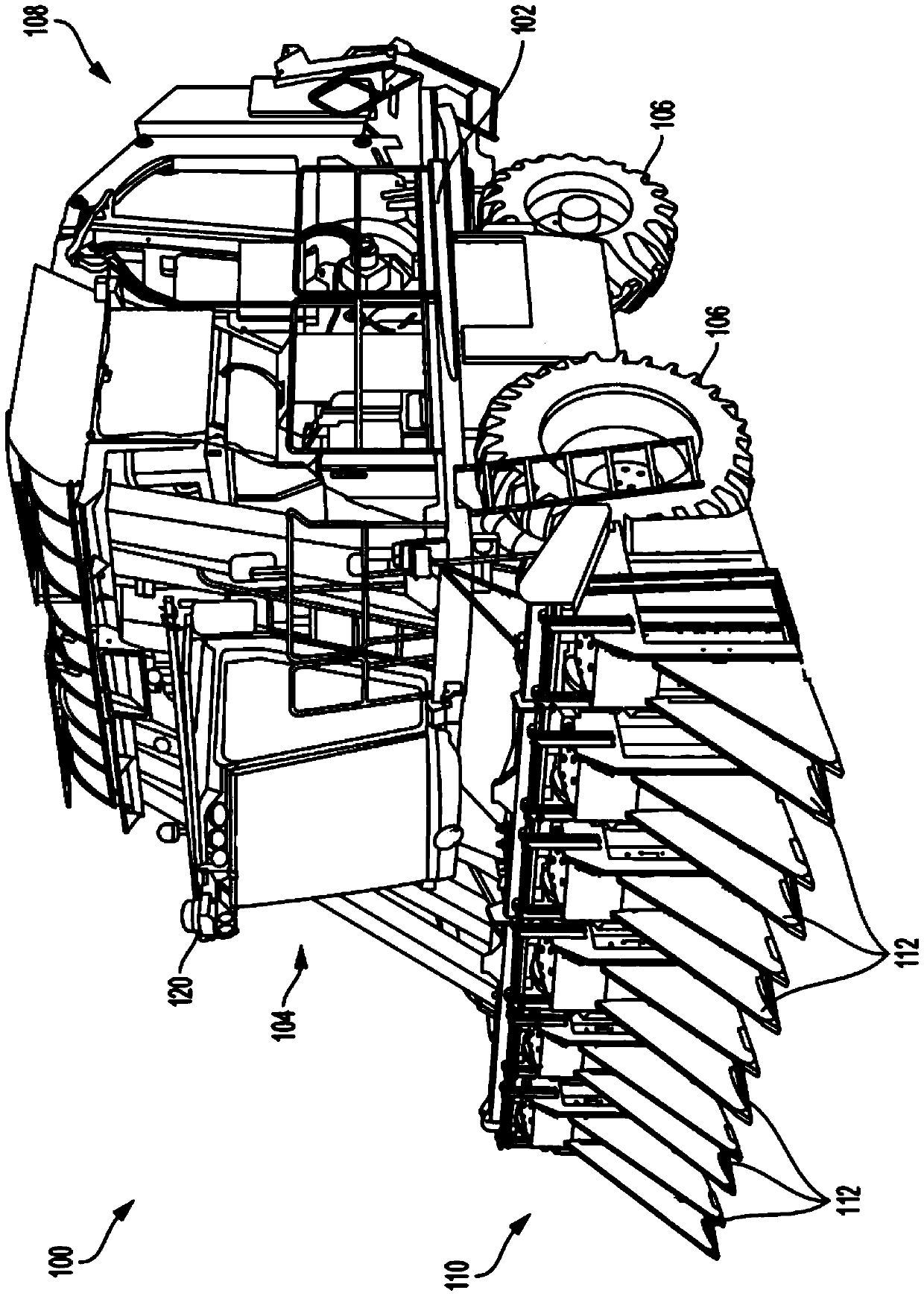

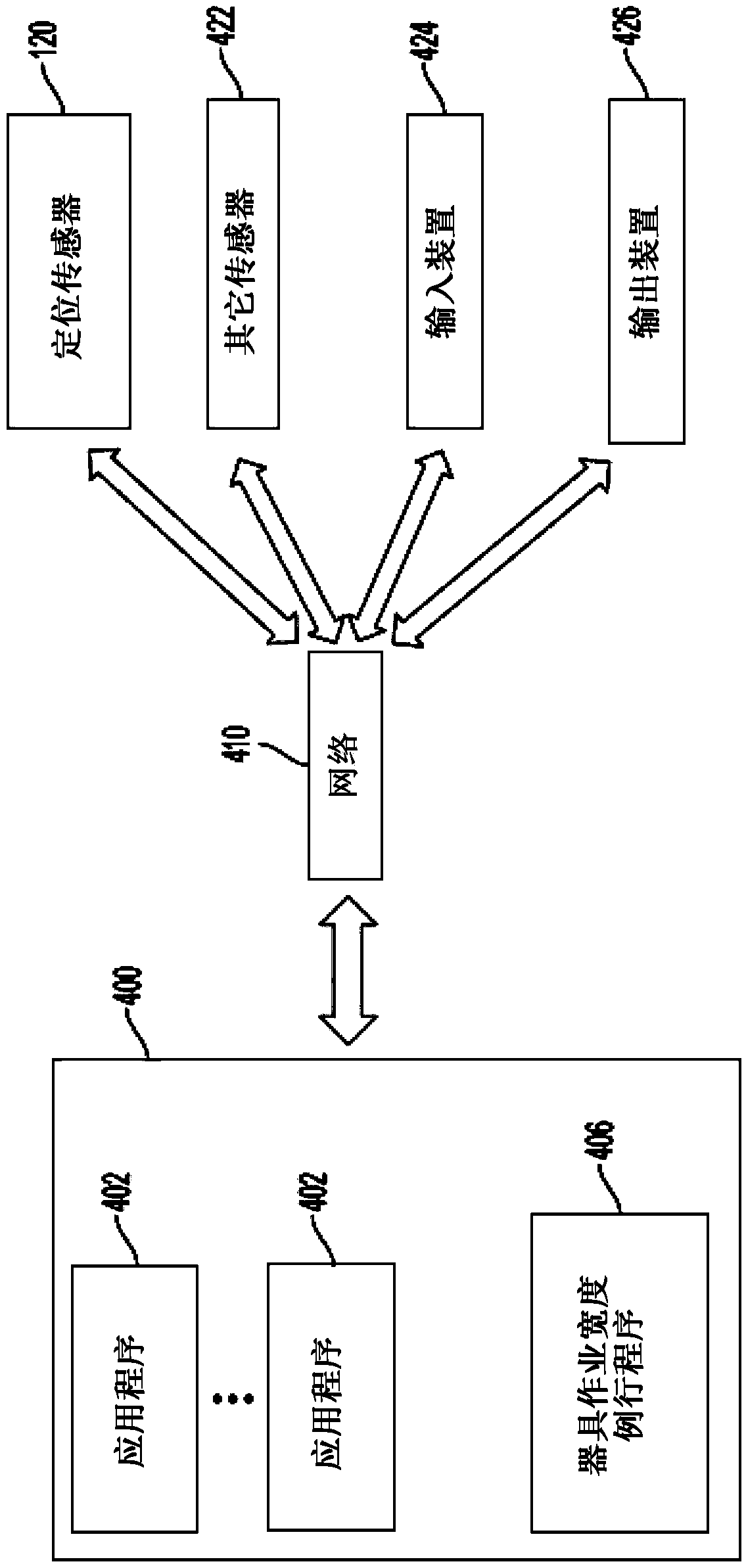

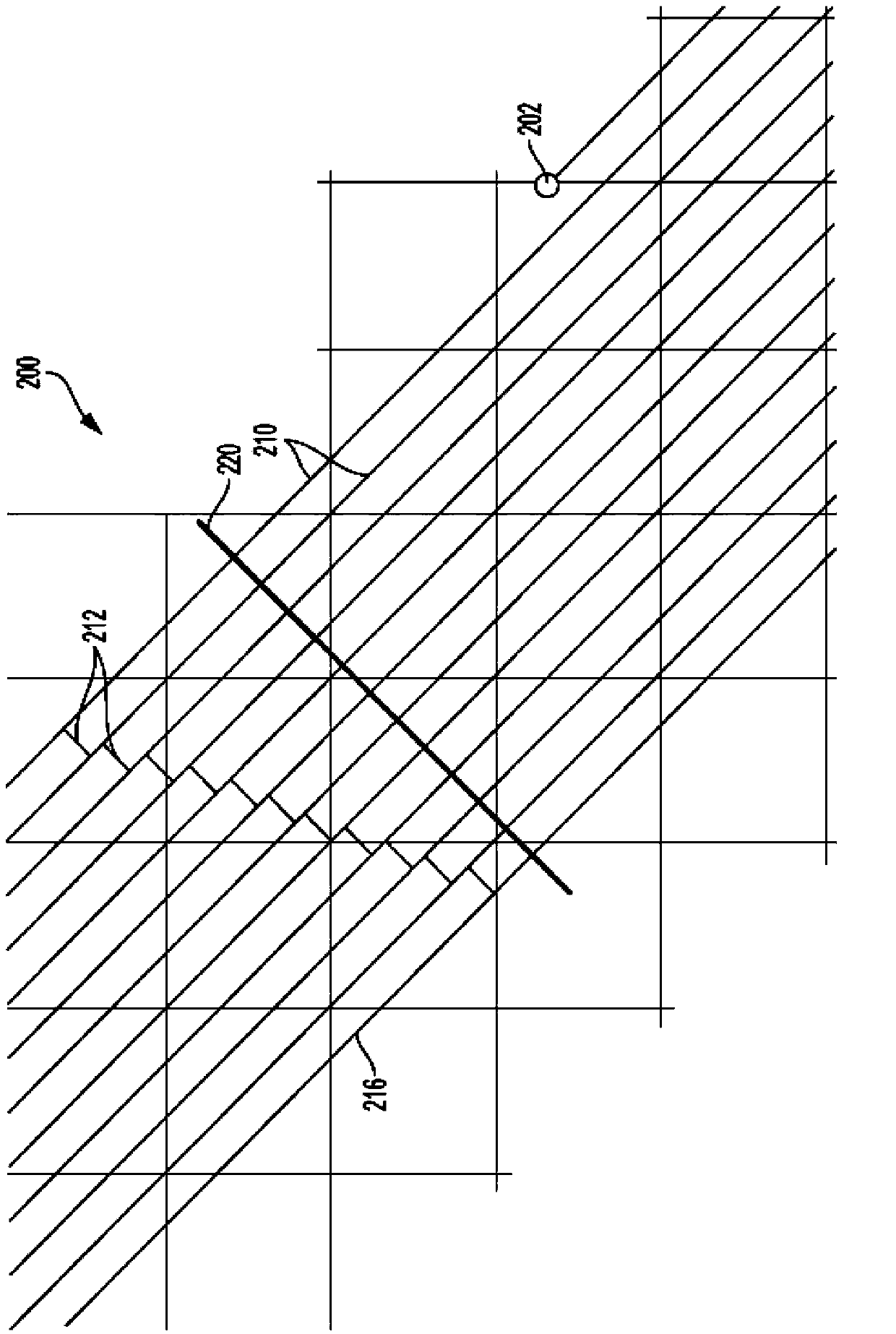

[0022] Many crops are grown and harvested in parallel rows. Because of this regular pattern, the machines are able to pass continuously for planting, harvesting and other tasks. When making measurements and estimates of fields such as acres and yields, an important parameter used in these calculations is the implement width. The working width of the appliance is the width of the working (cultivated land, planting and harvesting, etc.) area when the appliance passes through the field once. The appliance operating width may not be the same as the appliance physical width, which is the actual physical width of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap